signals is sent out through drive ICULN2003 to control relay’s ON/OFF. Then the

machine can work well under SCM uniform control.

Chapter II Typical Trouble Analysis

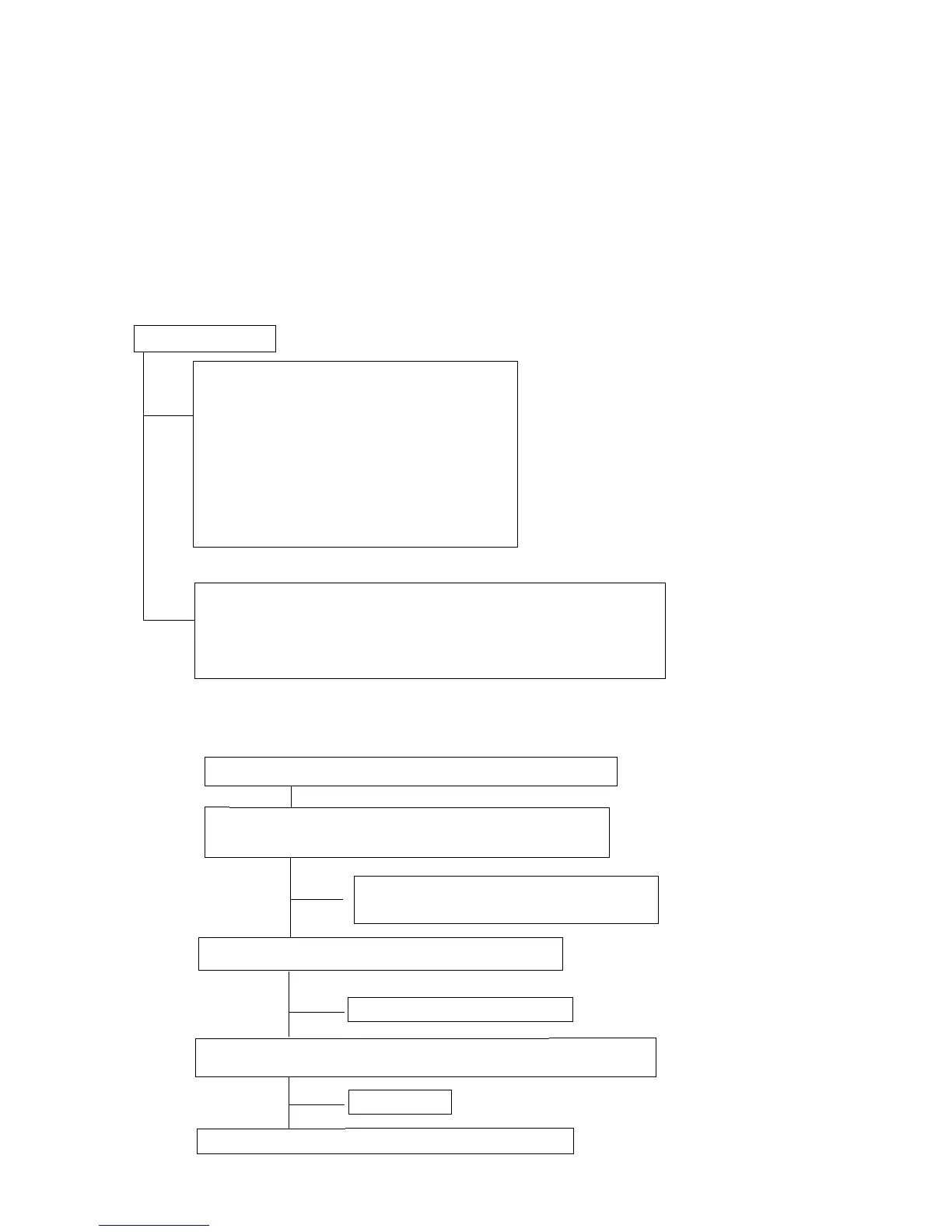

Trouble Detecting Flow for Abnormal Display

Display Abnormal

Display Failure Code

E1:Indoor temperature sensor failure:

sensor plug is in a bad contact with

control panel, or damage in sensor

E2:

Coil pipe temperature sensor:

sensor plug is in bad contact with

control panel, or damage in sensor.

Water-full indicator turns on and display

P2 (Refer to Section One Chapter I)

Display stroke-lack or indicator off :

1.Control panel is in a bad contact with display panel, then

need to re-insert plug .

2.

Damage in display panel, then need to replace display panel.

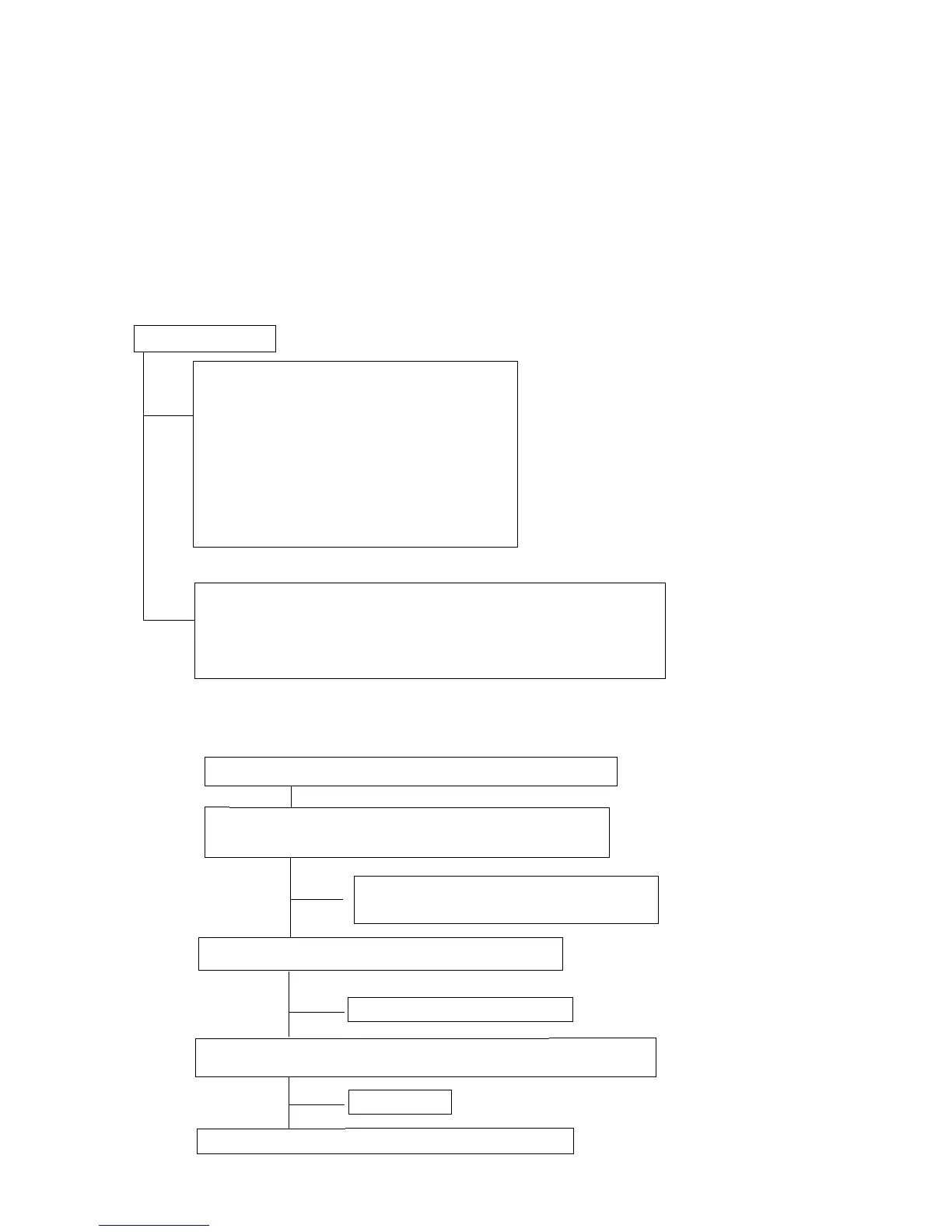

Trouble Shooting Flow for Machine Turn-On Failure

NO

Re-plug N line and L line , make them in

a good contact with film-inserted

After power-on , key "POWER "cannot run machine:

Check if power cord terminator (N, L) is in a good

contact with control panel film-inserted.

Check if there is 5V voltage out from 7805

YES

NO

YES

Replace main control panel

Check if the link between display panel and main control

panel is loose.

NO

YES

Re-link them

Replace main control panel and display panel .

Loading...

Loading...