16

Weld deposit “stringy” and incom-

plete

Weld deposit too thick

Rusty, painted, damp, oil or greasy workpiece

Rusty or dirty wire

Poor ground contact

Incorrect gas / wire combination

Torch moved over workpiece too quickly

Gas mixture incorrect

Torch moved over workpiece too slowly

Welding voltage too low

Ensure workpiece is clean and dry.

Ensure wire is clean and dry.

Check ground clamp/workpiece connection

Check on the manual for the correct combination

Move the torch slower

See shielding gas table

Move the torch faster

Increase welding voltage

14.0 PROTECTION GASES GUIDE

METAL

Mild steel

Aluminium

Stainless steel

Copper, Nickel and Alloys

GAS

Argon + CO2

Argon + CO2 + Oxygen

Argon (thick < 25mm)

Argon + Helium (thick > 25mm)

Argon + CO2 + Oxygen

Argon + Oxygen

Argon

Argon + Helium

NOTE

Argon controls spatters

Oxygen improves arc stability

Arc stability, good fusion and minimum spatter

Higher heat input suitable for heavy sections. Minimum porosity.

Arc stability

Minimum spatter

Suitable for light gauges because of low flowability of the weld

pool

Higher heat input suitable for heavy sections.

Contact the technical service of your gas supplier to know the percentages of the different gases which are the most suitable to your application.

15.0 TECHNICAL DATA INFORMATION GUIDE

11

11

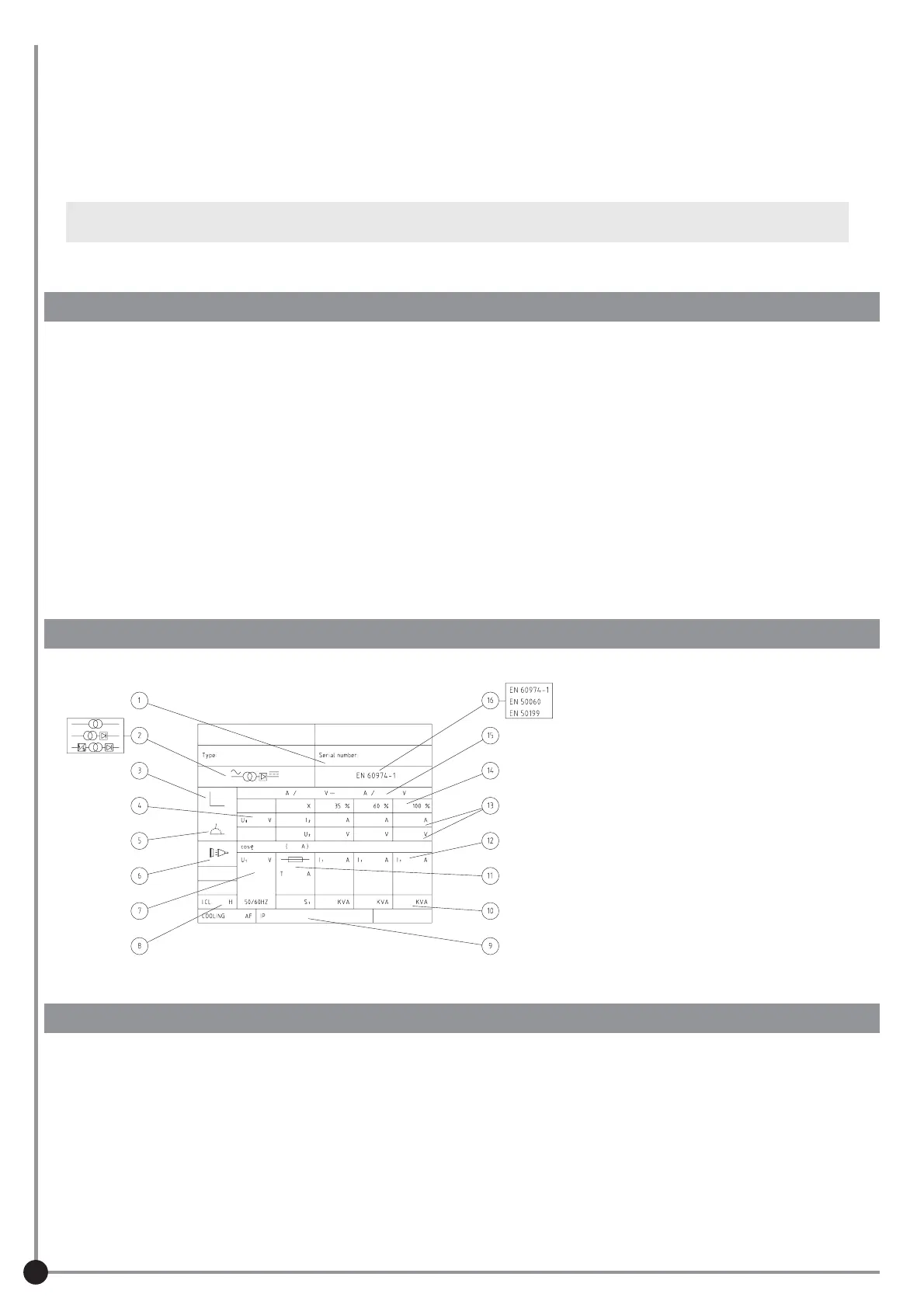

1 Serial Number of the Unit

22

22

2 Power source model

33

33

3 Kind of characteristic

44

44

4 Min. - Max rated No Load Voltage

55

55

5 Kind of welding

66

66

6 Symbol for the main supply and no. of phases

77

77

7 Rated value of the supply voltage

88

88

8 Code letter for degree of insulation

99

99

9 Protection degree

1010

1010

10 Power

1111

1111

11 Size of the necessary main fuse

1212

1212

12 Supply current

1313

1313

13 Welding supply and voltage

1414

1414

14 Power Factor

1515

1515

15 Control range (current / voltage)

1616

1616

16 Referring standard

16.0 WELDING HINTS AND MAINTENANCE

√√

√√

√ Always weld clean, dry and well prepared material.

√√

√√

√ Hold gun at a 45° angle to the workpiece with nozzle about 6mm from the surface.

√√

√√

√ Move the gun smoothly and steadily as you weld.

√√

√√

√ Avoid welding in very drafty areas. A weak pitted and porous weld will result due to air blowing away the protective welding gas.

√√

√√

√ Keep wire and wire liner clean. Do not use rusty wire.

√√

√√

√ Sharp bends or kinks on the welding cable should be avoided.

√√

√√

√ Always try to avoid getting particles of metal inside the machine since they could cause short circuits.

√√

√√

√ If available, use compressed air to periodically clean the hose liner when changing wire spools

IMPORTANT: Disconnect from power source when carrying out this operation.

√√

√√

√ Using low pressure air (20-30 PSI), occasionally blow the dust from the inside of the welder. This keeps the machine running cooler. Note: do

not blow air over the printed circuit board and electronic components.

√√

√√

√ The wire feed roller will eventually wear during normal use. With the correct tension the pressure roller must feed the wire without slipping. If

the pressure roller and the wire feed roller make contact (when the wire is in place between them), the wire feed roller must be replaced.

√√

√√

√ Check all cables periodically. They must be in good condition and not cracked.

Loading...

Loading...