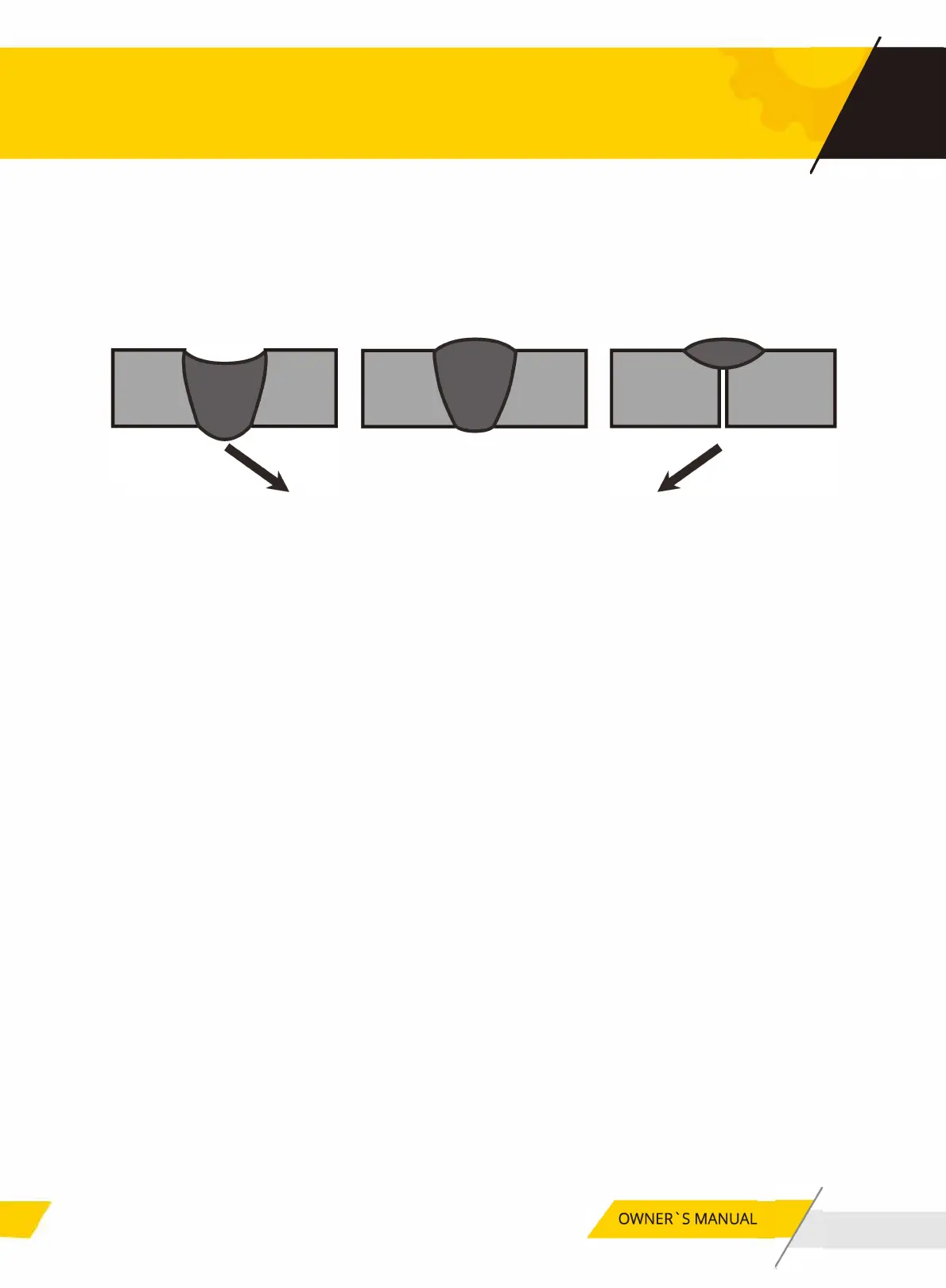

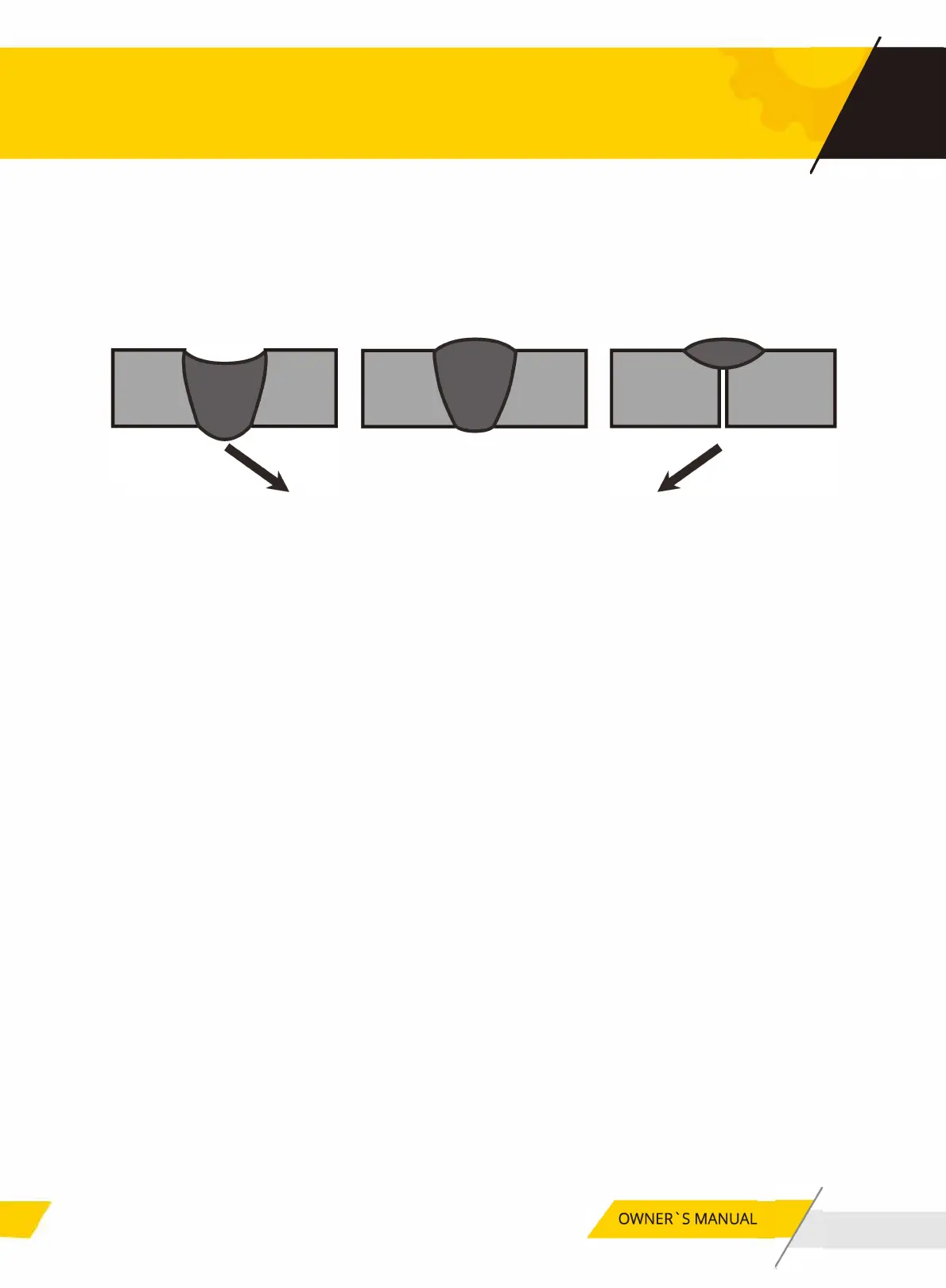

WELD PROBLEMS

Penetration(Workpiece Heat Control)

EXCESS PENETRION OR

BURN-THROUGH

Weld droops on top and

underneath, or falls through

entirely, making a hole.

PROPER PENETRION

Weld is visible underneath and

bulges slightly on top.

INADEQUE PENETRION

Weld does not penetrate the

joint fully, just on the surface.

PROFILE VIEWS

POSSIBLE CAUSES AND SOLUTIONS

1.

Reduce wire feed speed.

Decrease weld current.

2.

Increase travel speed and

ensure that travelspeed is kept

steady.

3.

Reduce wire feed speed.

POSSIBLE CAUSES AND SOLUTIONS

1.

Maintain 1 /2" or less stick out.

Keep arc on leading edge of

weld puddle. Hold MIG Gun at

proper angles.

2.

Reduce travel speed.

Increase weld current.

3.

Bevel thick workpieces, allow slight

gap, and weld in several passes.

4.

Increase wire feed speed.

Peld

38

Loading...

Loading...