6

Tip temperature

High soldering temperature will degrade the tip. Keep the temperature at the lowest as possible during work.

The tip temperature can recover quickly, which ensures efficient and effective soldering even at low

temperature. It also protects the soldered items from damage by high temperature.

Cleaning

Clean the tip regularly with a cleaning sponge; otherwise, oxides and carbides from solder and flux can form

impurities on the tip. These impurities can result in defective joints or reduce the tip's heat conductivity.

When you use the soldering iron frequently, be sure to loosen the tip and remove all oxides at least once a

week. It can help to maintain the tip's performance.

When not in use

Never leave the soldering iron at a high temperature for too long, as the tip's solder plating will be covered

with oxide, which can greatly reduce the tip's heat conductivity.

After use

Wipe the tip clean and tin it with fresh solder, which can prevent the tip from being oxidized.

Troubleshooting

Warning:

Disconnect the power plug before servicing. Failure to do so may result in electric shock. If the power cord is

damaged, it must be replaced by the manufacturer, its service agent or similarly qualified person in order to

avoid personal injury or damage to the unit.

Check 1. Whether the power cord or plug is connected or not?

→If no, connect it.

Check 2. Whether the fuse is damaged?

→If yes, replace the fuse with 3.15A/250V

Unable to set temperature

Knob damaged or Program fault

→Return dealer for maintenance

Check 1. Whether the iron heater is damaged?

→If yes, replace the iron heater

Check 2. Does the grounding spring touch the iron heater ?

→Reassembly

Check 3. Is the lead of iron heater twisted and inaccessible?

→If yes, replace soldering iron or return to dealer for repair

Refer to: How to determine the fault of heater or cord

Check 1. Is the tip temperature too high?

→If yes, set an appropriate temperature.

Check 2. Is the tip clean?

→If not, refer to Tip maintenance and Use.

Problem 5.

The tip temperature is different

from the set temperature.

Is the tip clean?

→If not, refer to Tip maintenance and Use.

→Or return dealer for maintenance

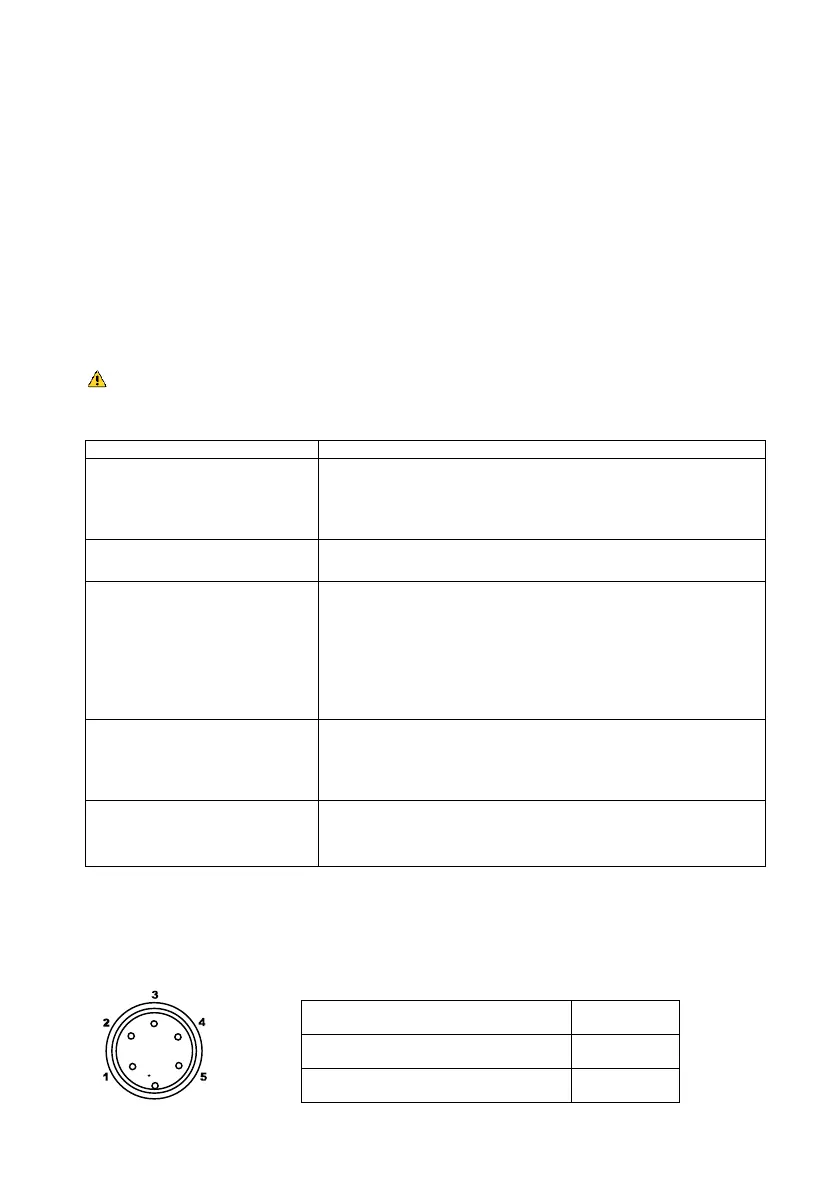

How to determine the fault of heater or cord.

Disconnect the plug and measure the resistance value between the connecting plug pins as follows.

If the values of 'a' and 'b' are far away from the normal values, replace the heater (sensor) and/or cord

assembly (refer to procedures 1 and 2).

If the value of 'c' is more than the normal value, remove the oxidization by lightly rubbing it with sandpaper or

steel wool.

a. Between pins 2&3 (Sensor)

b. Between pins 1& 4 (Heater)

c. Between metal case & Tip

Loading...

Loading...