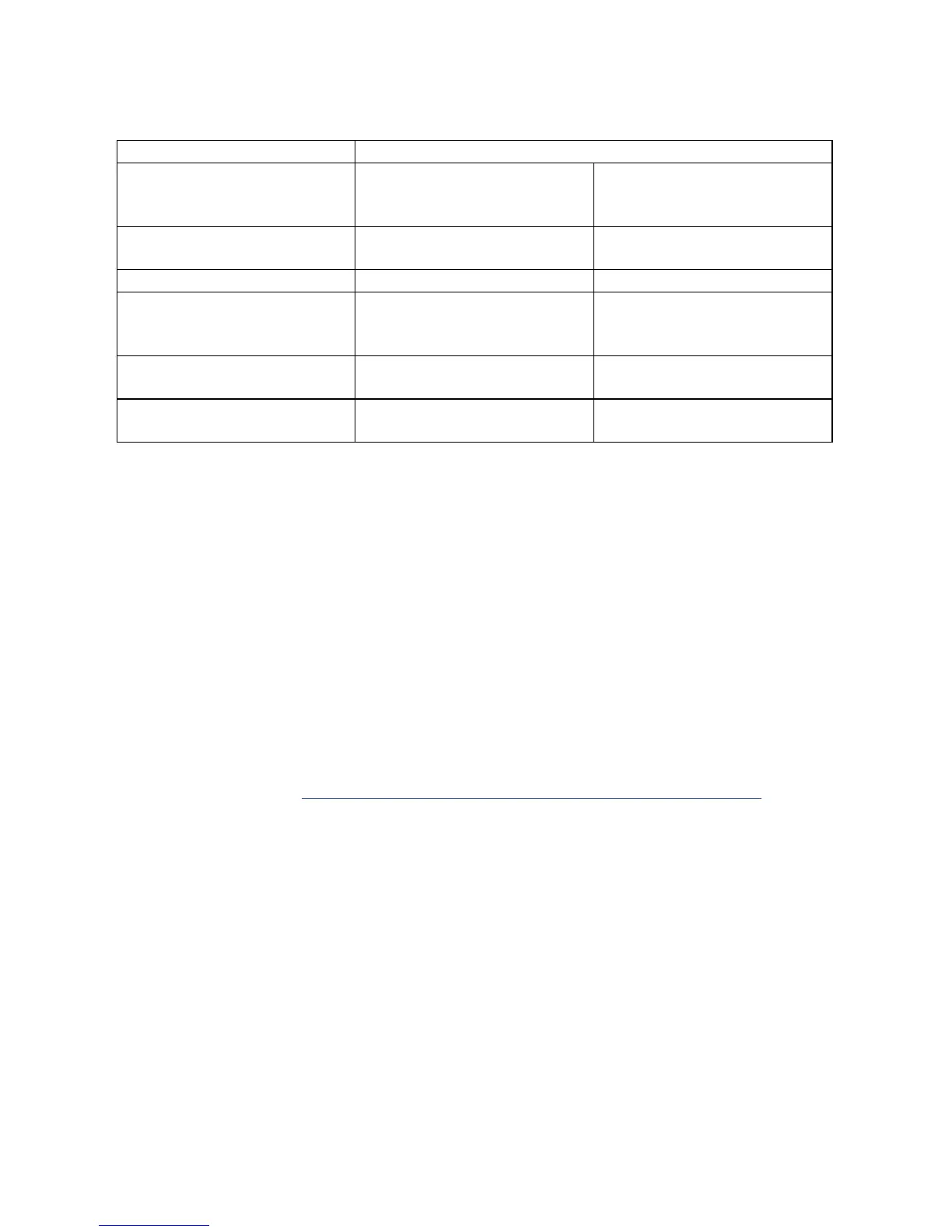

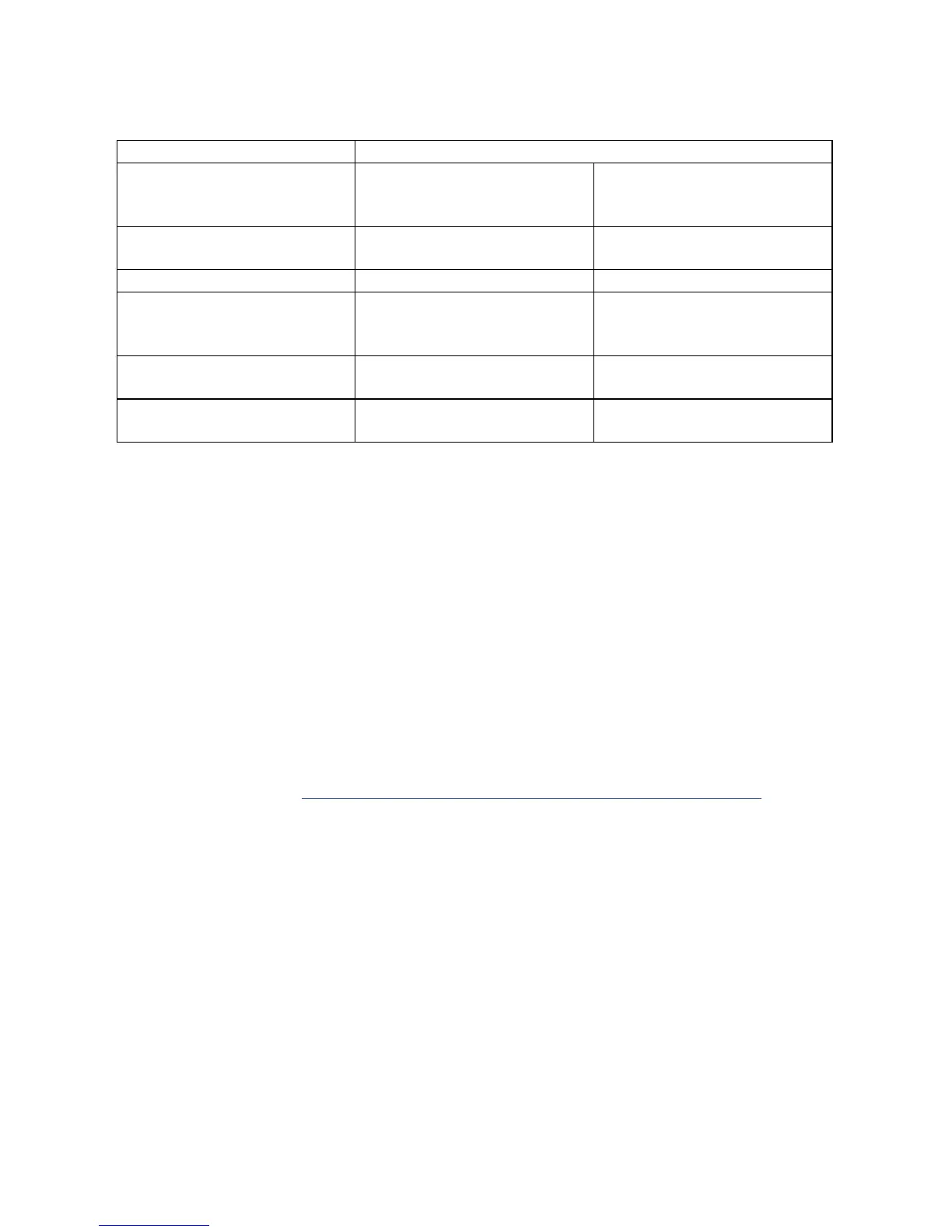

Global reference values at 20°C for the electrical resistivity of concrete of mature

structures (age > 10 years).

Environment Concrete resistivity ρ kΩcm

Ordinary Portland Cement

(CEM I)

Blast furnace slag cement

(>65% slag) or fly ash (>25%)

or silica fume (5%)

Very wet, submerged, splash

zone, fog room

5-20 30-100

Outside, exposed 10-40 50-200

Outside, sheltered, coated,

hydrophobised (not carbon-

ated) (20°C / 80% RH)

20-50 100-400

Outside sheltered as above

(Carbonated)

100 and higher 200-600 and higher

Indoor climate (carbonated)

20°C / 50%RH

300 and higher 400-1000 and higher

Resistivity mapping

Mapping out the resistivity of a structure enables useful interpretations to be made by comparing

the values against those in the above table. Please note that the temperature correction described

earlier should be taken into consideration. If exposure conditions are the same, varying resistivity

values may indicate local variations of the water/cement ratio. If it is known that the concrete is

homogenous throughout the structure, then the resistivity measurements can be used to determine

how relatively wet and dry the various areas are.

Correlation to permeability

Studies have shown that resistivity can be directly correlated to chloride diffusion rate. On site

mapping of the resistivity of a concrete structure will identify the most permeable areas. Such

areas are more likely to be susceptible to chloride penetration. The Resipod model with 38 mm

spacing conforms to the AASHTO T 358 Surface Resistivity Test Method which uses surface

resistivity as an indication of the permeability of concrete. Details of the test can be found on the

official AASHTO website http://tig.transportation.org/Pages/SurfaceResistivityTest.aspx.

On site assessment of curing efficiency

Resistivity measurements may be used on site to determine premature drying of concrete. This

is a particularly important application in hot countries where premature drying out can lead to

structural weakening due to non-completion of the hydration reaction. The method uses the strong

dependence of resistivity on the humidity of the concrete. Site measurements are compared with

measurements made on a saturated reference cylinder to define a relative resistivity which can be

used to isolate the effects of humidity and thereby determine premature drying. Please refer to

“Electrical resistivity as a tool to on site assessment of curing efficiency – by L. Fernandez Luco,

C. Andrade and M.A. Climent (June 2009)”.

Resistivity measurements and cathodic protection systems

The effectiveness of a cathodic protection system depends very much on the resistivity of the

concrete. Mapping out the resistivity prior to installation allows the structure to be divided into

separate zones requiring different levels of current flow.

Loading...

Loading...