WINTER OPERATION – When using the heater in winter ensure the flue is

not blocked by snow or fallen leaves etc. When not in use make sure the heater

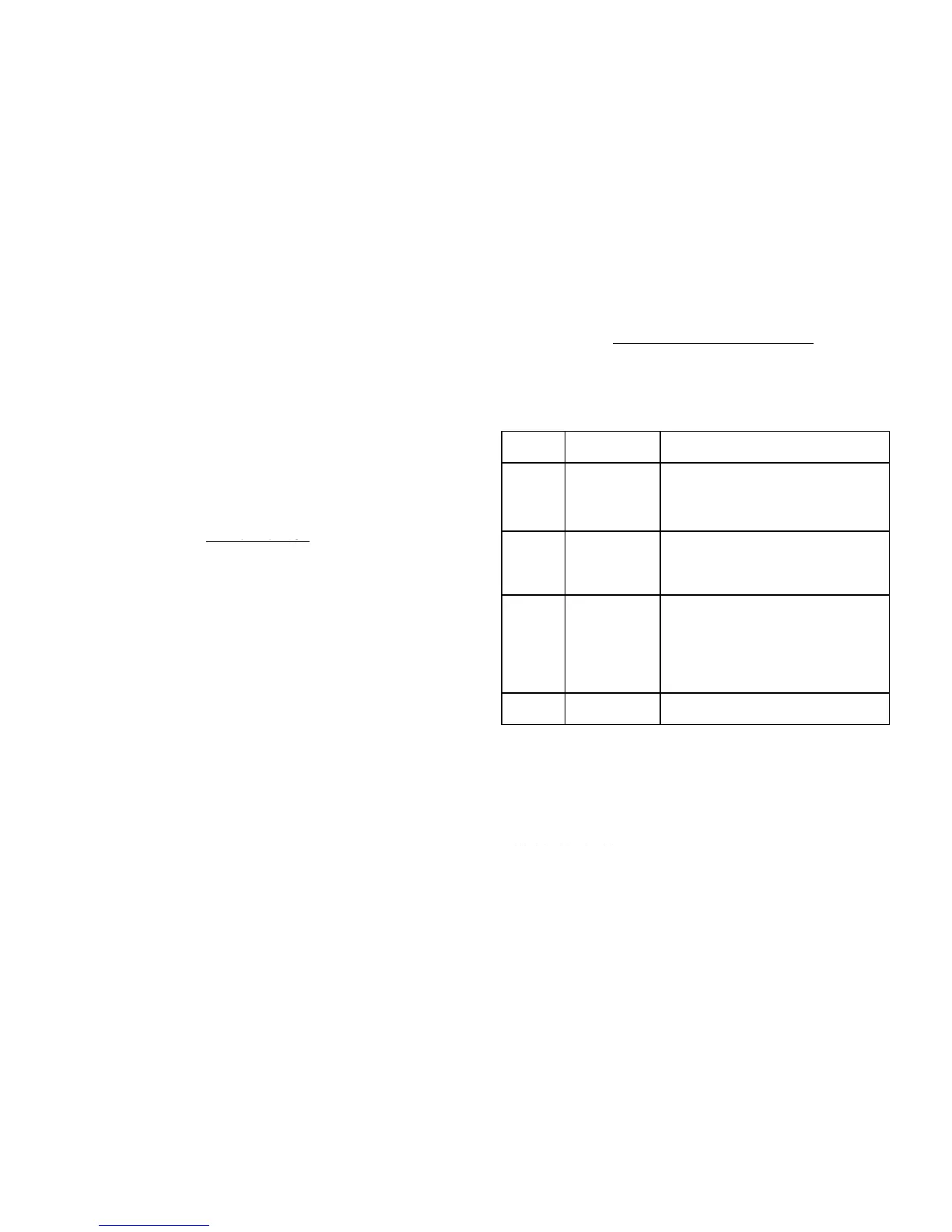

FAULT FINDING & LOCKOUTS

The heater is equipped with an electronic diagnostic system which will detect

fault conditions ranging from poor gas or DC supply to internal heater

.

ENERGY FAILURE – in the event of an energy failure isolate the gas supply.

When the energy supply has been restored clear any lockouts which may have

occurred and continue normal operation.

a number of times, pause, and repeat until switched off. Count the number of

flashes and refer to the table below.

Number

of Flashes

Fault Remedy

use

to protect the PCB in the event of an overload on the 12V circuit. This is easily

replaced and the location of the fuse is outlined on page 11.

1

No Flame

Detected

Check gas supply making sure there is gas in

the bottle and no blockage in the gas line.

Ensure propane is used at temperatures below

+5°C. Clear lockout as described below.

Check there is water in the appliance We

To clean and sterilise inside the water heater use diluted sterilising fluid and

fully rinse through with clean water afterwards. The outside of the appliance

should not normally require cleaning. If it does, isolate the electrical supplies

and wipe down with a soft, damp cloth only. Allow to fully dry before

recommend you wait at least 5 to 10 minutes to

allow the heater to cool before clearing lockout

as described below.

Minimum operating voltage is 10V, maximum

.

If descaling of this appliance is required, this can be done using ‘Kettle Klear’ or

an equivalent product and fully rinse through with clean water afterwards.

The appliance should be checked and maintained (if required) periodically by a

competent person within a maximum of 2 years according to the practice in the

3

Low/High

Supply Voltage

is 15V, when measured at the heater. Check

battery voltage. If between 10V and 15V,

check connections between heater and battery.

Check alternator or external battery charging.

Clear lockout as described below.

country where it is used and these instructions.

We recommend annual testing of gas soundness and combustion by an

accredited LPG gas engineer.

5

Other / internal

fault

Attempt to clear lockout as detailed below. If

this fails, contact Propex directly.

Clearing Lockouts

Lockouts are cleared by moving the switch from on position to off position then

osition. The complete sequence of switch movements mus

e

completed within 2.5 seconds for a lockout to be successfully cleared. If there is

air in the gas line, e.g. after a gas bottle change, the water heater may require

several attempts before it lights. If this does not clear the Overheat lock out

remove the front cover exposing the PCB and press the red button on the manual

Note: A cycling of the power supply to the unit will not clear a lockout.

If problems persist contact Propex Heatsource Ltd on 023 8058 2555

-4 -

Loading...

Loading...