12

DESCALING IMMERSION HEATER(S)

Before removing the immersion heater(s) the unit

must be drained. Ensure the water, electrical

supply, boiler and solar primary circuit are OFF

before draining. Attach a hosepipe to the drain

cock having sufficient length to take water to a

suitable discharge point below the level of the unit.

Open a hot tap close to the unit and open drain cock

to drain unit.

MAINTENANCE

MAINTENANCE REQUIREMENTS

Unvented hot water systems have a continuing

maintenance requirement in order to ensure safe

working and optimum performance. It is essential

that the relief valve(s) are periodically inspected and

manually opened to ensure no blockage has oc-

curred in the valves or discharge pipework. Similarly

cleaning of the strainer element and replacement of

the air in the expansion vessel will help to prevent

possible operational faults.

The maintenance checks described below should be

performed by a competent installer on a regular

basis, e.g. annually to coincide with boiler mainte-

nance.

SAFETY VALVE OPERATION

Manually operate the temperature/pressure relief

valve for a few seconds. Check water is discharged

and that it flows freely through the tundish and

discharge pipework. Check valve reseats correctly

when released. NOTE: Water discharged may be

very hot!

Repeat the above procedure for the expansion valve.

STRAINER

Turn off the cold water supply, boiler and immersion

heaters. The lowest hot water tap should then be

opened to de-pressurise the system. Remove the

pressure reducing valve cartridge to access the

strainer mesh. Wash any particulate matter from the

strainer under clean water. Re-assemble ensuring

the seal is correctly fitted, DO NOT use any other

type of sealant.

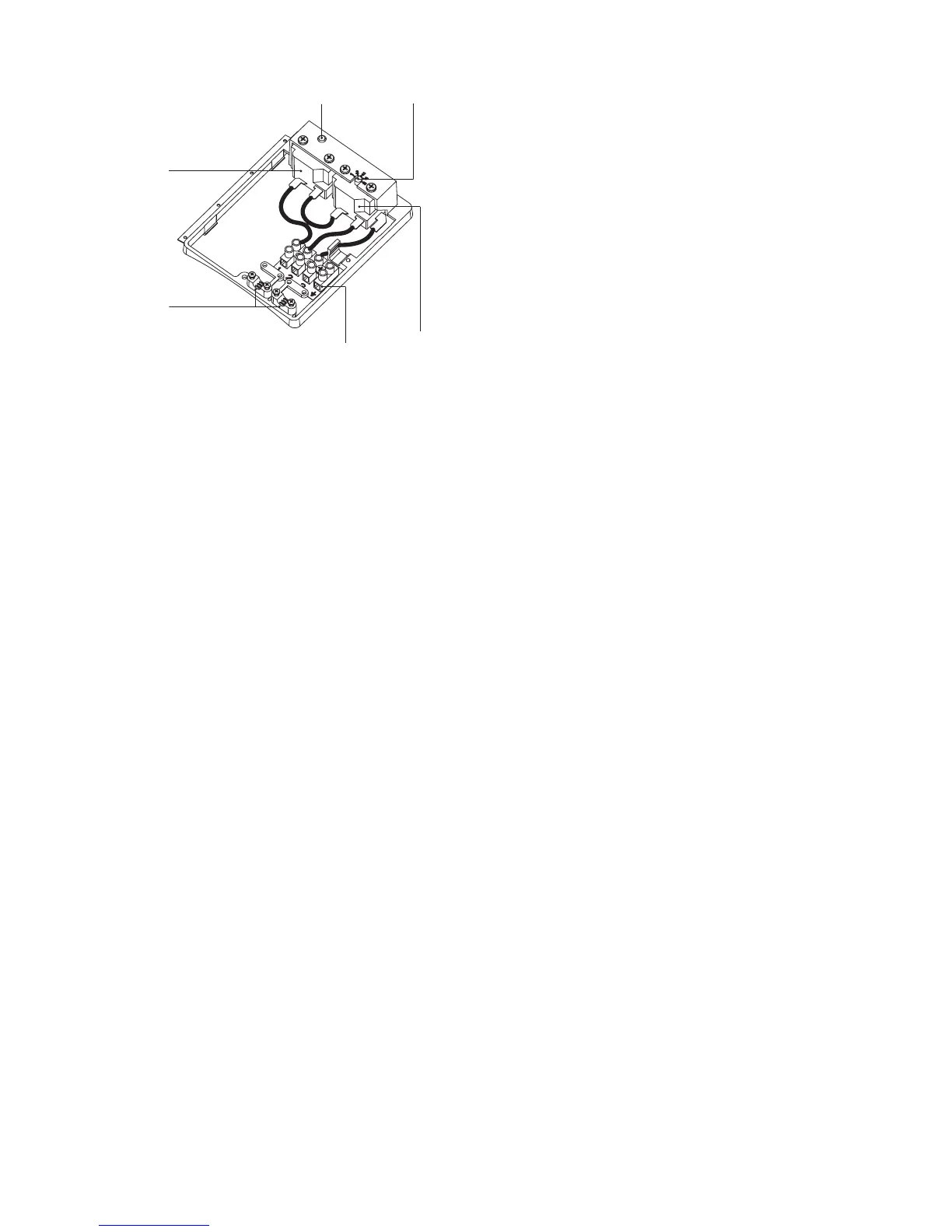

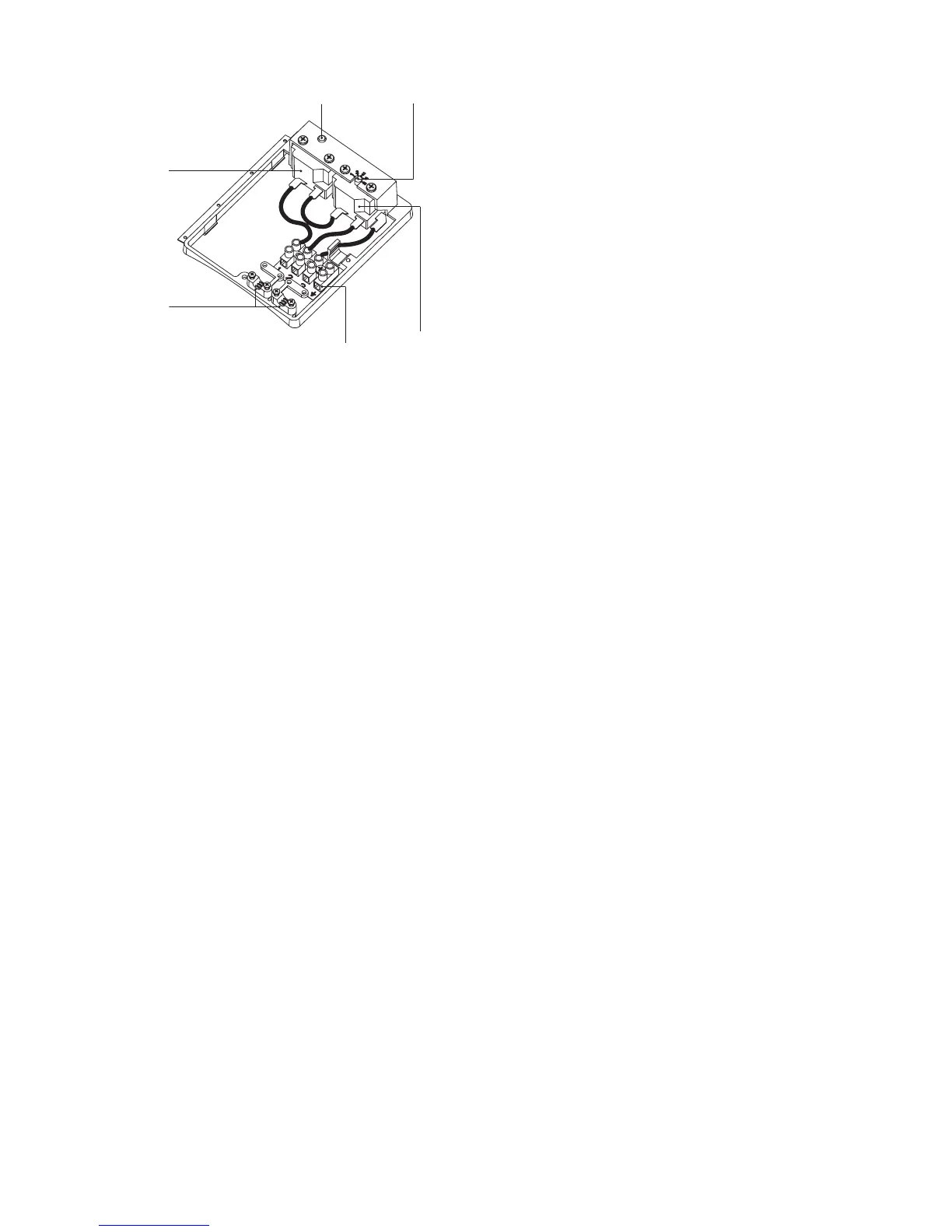

INDIRECT

THERMAL

CUT-OUT

CABLE

CLAMPS

TERMINAL BLOCK

INDIRECT

THERMOSTAT

THERMOSTAT

ADJUSTMENT

INDIRECT THERMAL

CUT-OUT RESET BUTTON

NOTE: THE HOUSING COVER AND

ELEMENT ASSEMBLY HAVE BEEN REMOVED

FROM THIS VIEW FOR CLARITY

Fig. 10: Indirect thermostat and thermal cut-out

DIRECT MODELS:

Open the cover(s) to the immersion heater

housing(s) and disconnect wiring from the

thermostat mounted on top of the immersion

heater(s). Remove the thermostat by carefully

pulling outwards from the immersion heater.

Unscrew immersion heater backnut(s) and

remove immersion heater from the unit. A key

spanner is supplied with the Pullin Evolution

Solar unit for easy removal/tightening of the

immersion heater(s). Over time the immersion

heater gasket may become stuck to the mating

surface. To break the seal insert a round bladed

screwdriver into one of the pockets on the

immersion heater and gently lever up and down.

INDIRECT MODELS:

Open the cover(s) to the immersion heater

housing(s) and disconnect wiring from immer-

sion heater(s). Remove the thermostat by

carefully pulling outwards from the immersion

heater. Remove thermostat capillary sensors

from the pockets on the immersion heater.

Unscrew immersion heater backnut(s) and

remove immersion heater from the unit. A key

spanner is supplied with the Pullin Evolution

Solar unit for easy removal/tightening of the

immersion heater(s). Over time the immersion

heater gasket may become stuck to the mating

surface. To break the seal insert a round bladed

screwdriver into one of the pockets on the

immersion heater and gently lever up and down.

Carefully remove any scale from the surface of

the element(s). DO NOT use a sharp implement

as damage to the element surface could be

caused. Ensure sealing surfaces are clean and

seals are undamaged, if in doubt fit a new

gasket.

Replace immersion heater(s) ensuring the lower

(right angled) element hangs vertically down-

wards towards the base of the unit. It may be

helpful to support the immersion heater using a

round bladed screwdriver inserted into one of

the thermostat pockets whilst the backnut is

tightened. Replace thermostat capillaries into

pocket (indirect models). Replace the immersion

heater thermostat by carefully plugging the two

male spade terminations on the underside of the

thermostat head into the corresponding termina-

tions on the element. Rewire, check, close and

secure immersion heater housing cover(s).

Loading...

Loading...