15

15

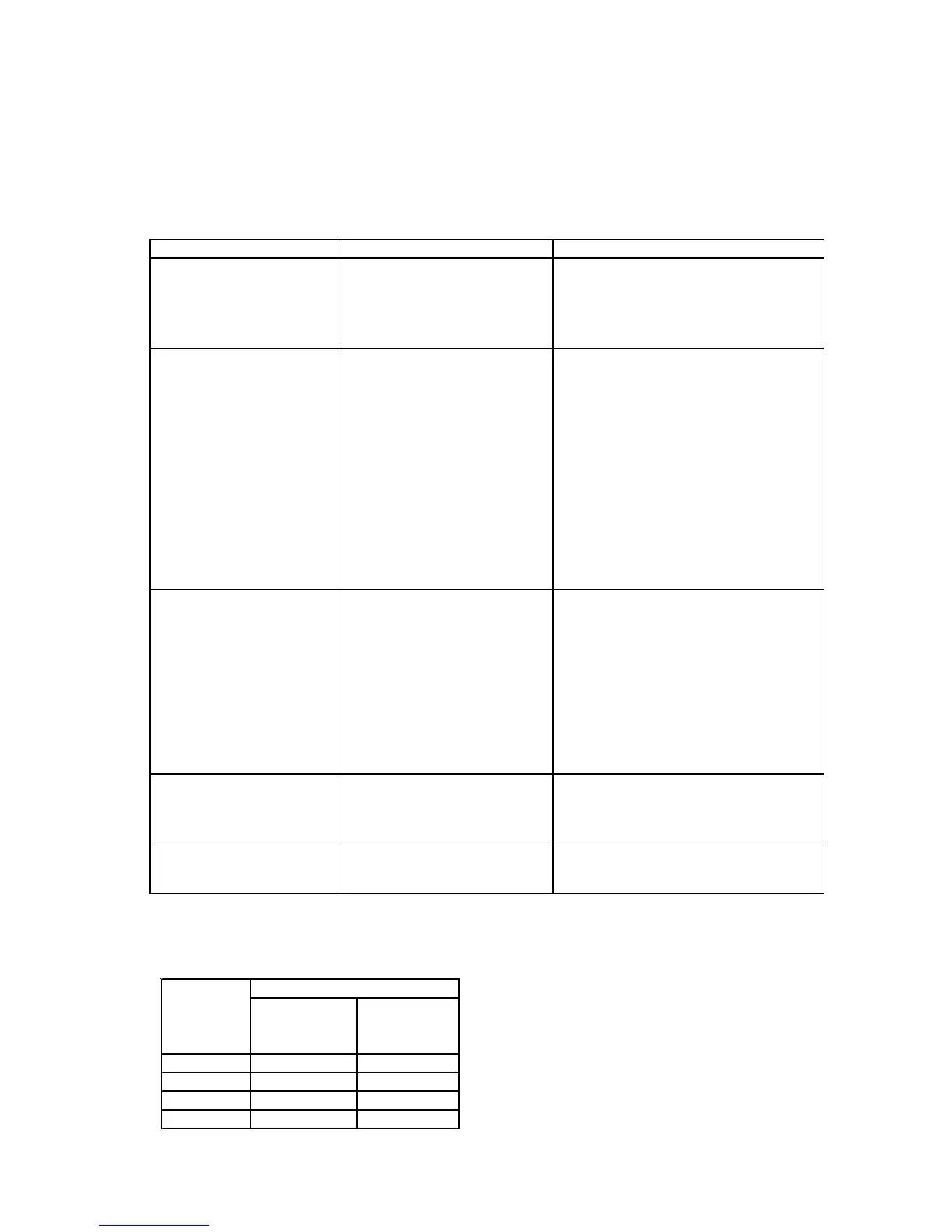

FAULT FINDING

The Fault Finding chart below will enable operational

faults to be identified and their possible causes

rectified. Any work carried out on the Pullin Evolution

Solar water heater and its associated controls MUST

be carried out by a competent installer for unvented

water heating systems. In case of doubt contact

Service Support.

DO NOT TAMPER WITH ANY OF THE SAFETY

VALVES OR CONTROLS SUPPLIED WITH THE

PULLIN EVOLUTION SOLAR AS THIS WILL

INVALIDATE ANY GUARANTEE

Table 3: Fault Finding Chart

WARNING

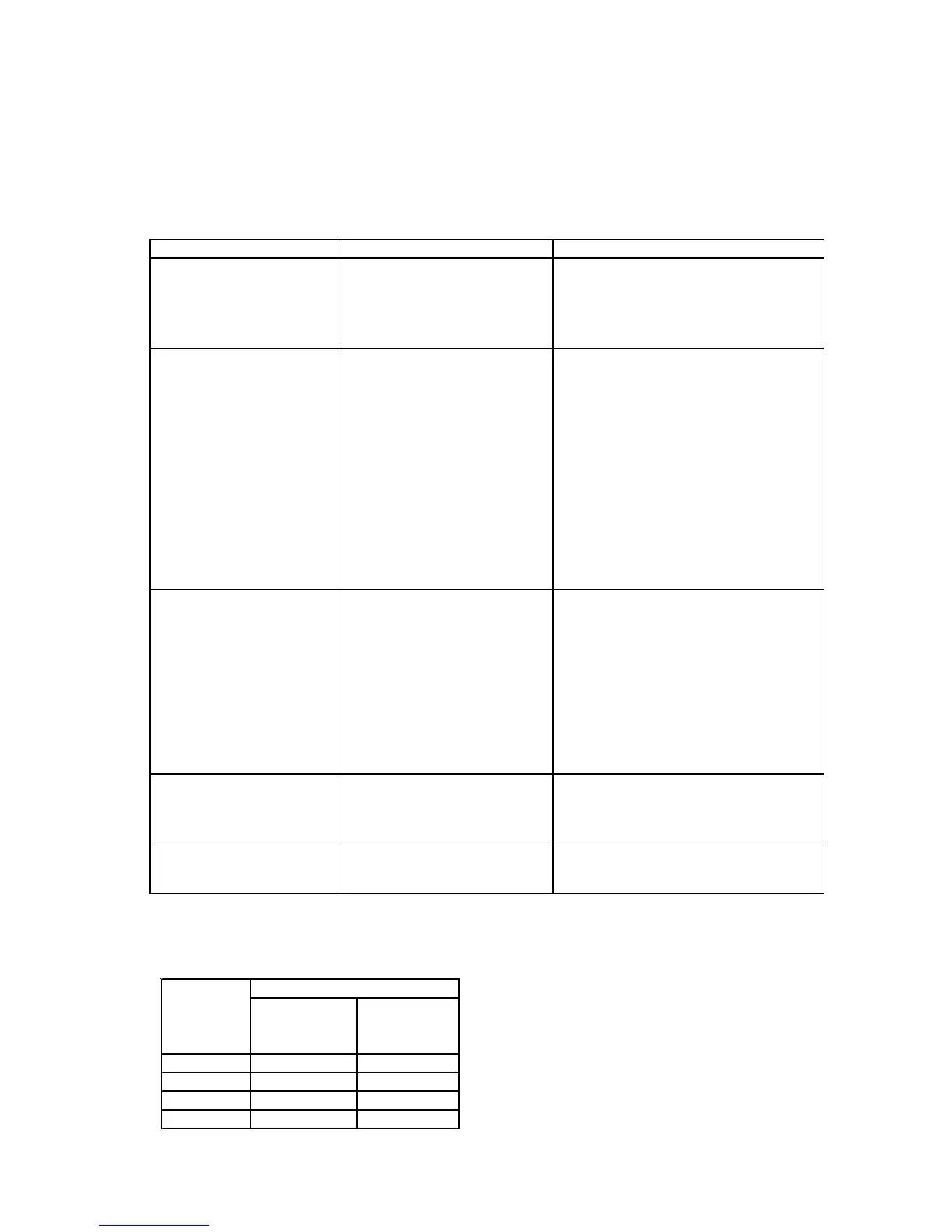

Table 4: Standing heat losses (based on an ambient

air temperature of 20

o

C and a stored water tem-

perature of 65

o

C)

OTHER INFORMATION

ENVIRONMENTAL INFORMATION

Pullin products are manufactured from many recyclable

materials. At the end of their useful life they should be

disposed of at a Local Authority Recycling Centre in

order to realise the full environmental benefits.

Insulation is by means of an approved CFC/HCFC free

polyurethane foam with an ozone depletion factor of

zero.

per day

(kWh/24h)

per year

(kWh/365d)

190 2.11 770

210 2.30 840

250 2.45 894

300 2.72 993

Nominal

Capacity

(litres)

Standing Heat Loss

FA ULT POSSIBLE CAUSE REMEDY

1. Mains supply off. 1. Check and open stop cock.

2. Strainer blocked. 2. Turn off water supply. Remove strainer

and clean (see Maintenance section).

3. Cold W at e r Combinatio n V alve

incorrectl

ramme.

4. INDIRECT bo iler not w orking. 4. Che ck boiler operat ion. If fault is

suspected consult boiler manufact urer's

inst ruct ions.

5. INDIRECT thermal cut-out has

operated.

5. Check. Reset by pushing button on cut-

out. Check operation of indirect

thermostat.

6. INDIRECT motorised valve not

connected correctly.

6. Check wiring and/or plumbing

connections to motorised valve (see Fig. 8).

1. INTERMITTENTLY

Expansion Vessel charge pressure

has reduced below 3.5bar.

1. See Maintenance section for re-charging

procedure.

2. CONTINUALLY

a. Cold W at er Combinat ion V alve

Pressure Reducer not w orking

correctly.

2a. Check pressure from Cold Water

Combinat ion V alve. If gre at e r than 3.5bar

replace Pressure Reducer cart ridge.

b. Expansion Valve seat damaged. 2b. Remove Expansion Valve cartridge.

Che ck condit ion of seat . If ne cessary fit

new Expansion Valve cartridge.

Wat er discharges from T&P

Re lief Valve

1. T he rmal cont rol failure NOT E

w at er w ill be ve ry hot .

1. Sw itch off pow e r t o imme rsion heat er(s)

and shut down boiler. DO NOT turn off

wat er supply. W hen discharge st ops check

all t he rmal cont rols, replace if fault y.

Milky water

1. Oxygenat ed w ater. 1. W ater from a pressurised system releases

oxygen bubbles when flowing. The

milkiness w ill disappear afte r a short w hile .

No hot water flow

Water from hot taps is cold

Wat er discharges from

Expansion Valve

Loading...

Loading...