8

INSTALLATION - DIRECT UNITS

PLUMBING CONNECTIONS

Direct units require the following pipework connec-

tions.

• Cold water supply to and from inlet controls.

• Outlet to hot water draw off points.

• Discharge pipework from valve outlets to tundish.

ELECTRICAL SUPPLY (FIG. 6)

Pullin Evolution Solar units are fitted with two 3kW

immersion heaters as standard. It is recommended

that these should be wired via a suitable controller

to BSEN 60730. The Pullin Evolution Solar MUST

be earthed.

All wiring to the unit must be installed in accordance

with the latest IEE Wiring Regulations and the circuit

must be protected by a suitable fuse and double pole

isolating switch with a contact separation of at least

3mm in both poles. The Live and Neutral connections

are made directly onto the combined thermostat and

thermal cut-out located under the terminal cover(s)

mounted on the front of the unit. The earth connec

tion should be made to the earth connection located

to the side of the immersion heater boss(es). The

supply cable must be routed through the cable gland

located on the unit casing beneath the terminal

housing.

DO NOT operate the immersion heaters until the

Pullin Evolution Solar has been filled with water.

INSTALLATION - SOLAR PRIMARY

CONNECTION TO SOLAR PRIMARY CIRCUIT

The lower (solar) coil of the Pullin Evolution Solar

must be connected to a fully pumped solar primary

circuit. The connections are suitable for 22mm

copper pipe direct to the compression fittings

provided. The connections are also threaded 3/4”

BSP male parallel should BSP be required.

The solar primary circuit should have its own

dedicated circulating pump and safety controls which

must be installed as per the manufacturers instruc-

tions.

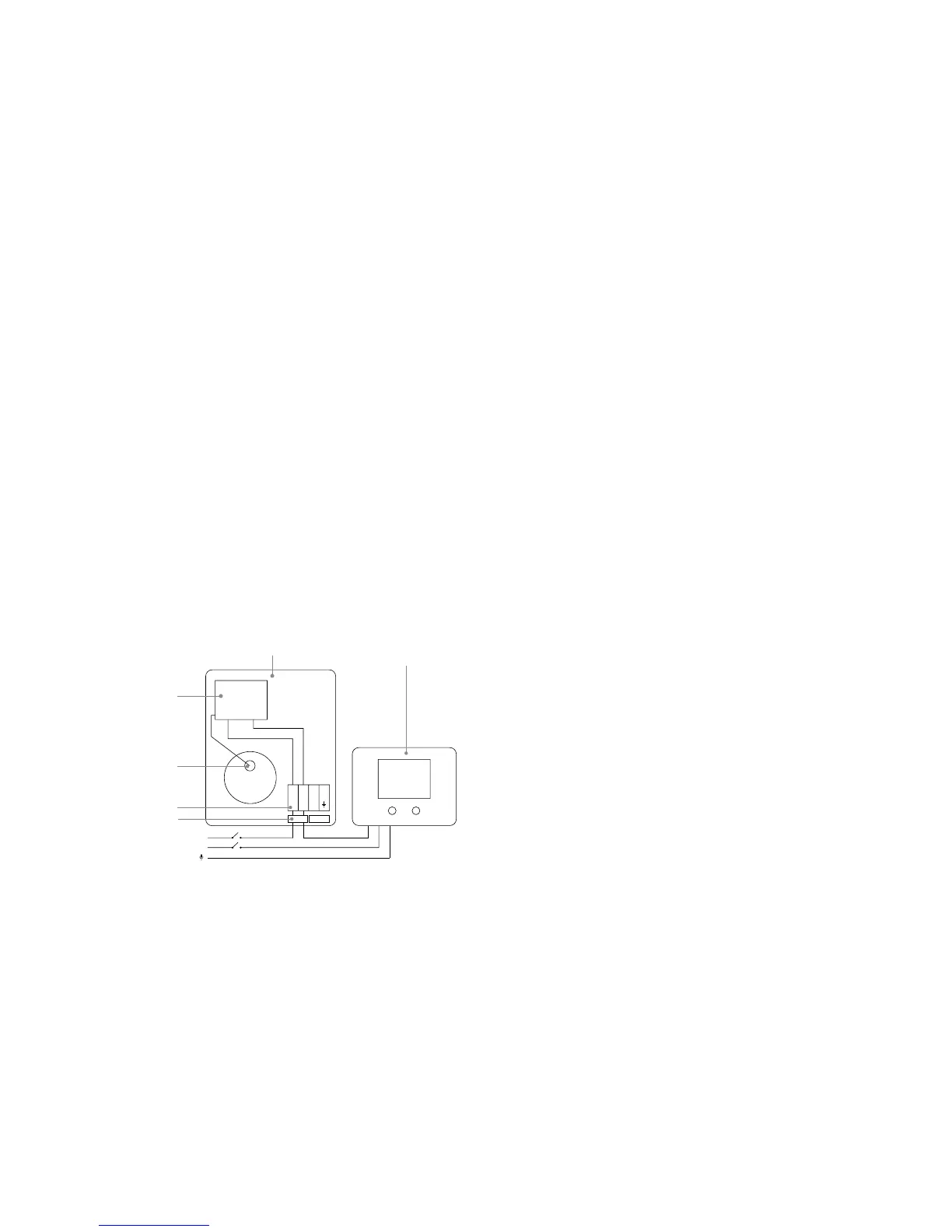

CONTROL OF SOLAR PRIMARY CIRCUIT

Temperature control of the Pullin Evolution Solar

must be carried out using a suitable proprietory

Solar Controller/Programmer. The cylinder tempera

ture sensing probe (supplied with the solar control

ler) should be fully insterted into the pocket provided

on the Pullin Evolution Solar and its cable secured

using the cable clamps on the controls housing (see

Fig.7).

Connection to the solar controller should be in

accordance with manufacturer’s instructions. The

solar controller should be programmed to give a

cylinder temperature of approximately 60°C

(maximum 70°C).

SAFETY

DISCONNECT FROM THE MAINS SUPPLY BEFORE

REMOVING ANY COVERS. Never attempt to replace

the immersion heater(s) other than with the recom-

mended Pullin immersion heater(s).

DO NOT BYPASS THE THERMAL CUT-OUT(S) IN

ANY CIRCUMSTANCES. Ensure the two male spade

terminations on the underside of the combined

thermostat and thermal cut-out are pushed firmly

onto the corresponding terminations on the element

plate assembly.

In case of difficulty contact service support; contact

details available at the back of this booklet.

Fig. 7: Solar Control Connections

The solar controller and solar primary circulation

pump must be wired via the over-temperature cut-

out mounted in the lower solar controls housing (see

Fig. 7). This will ensure that the heat input to the

solar coil is interrupted in the event of the cylinder

over-heating. There must also be suitable check

(non-return) valves installed in the solar primary

flow and return to prevent the possibility of any

thermo-syphoning if the solar circulation is stopped.

123

SOLAR DIFFERENTIAL

CONTROLLER

(NOT SUPPLIED)

SOLAR CYLINDER

CONTROLS HOUSING

CYLINDER

TEMPERATURE

CONTROL

PROBE

TERMINAL

BLOCK

OVER

TEMPERATURE

CUT OUT

L

N

CABLE

CLAMPS

Loading...

Loading...