IL THRUSTER

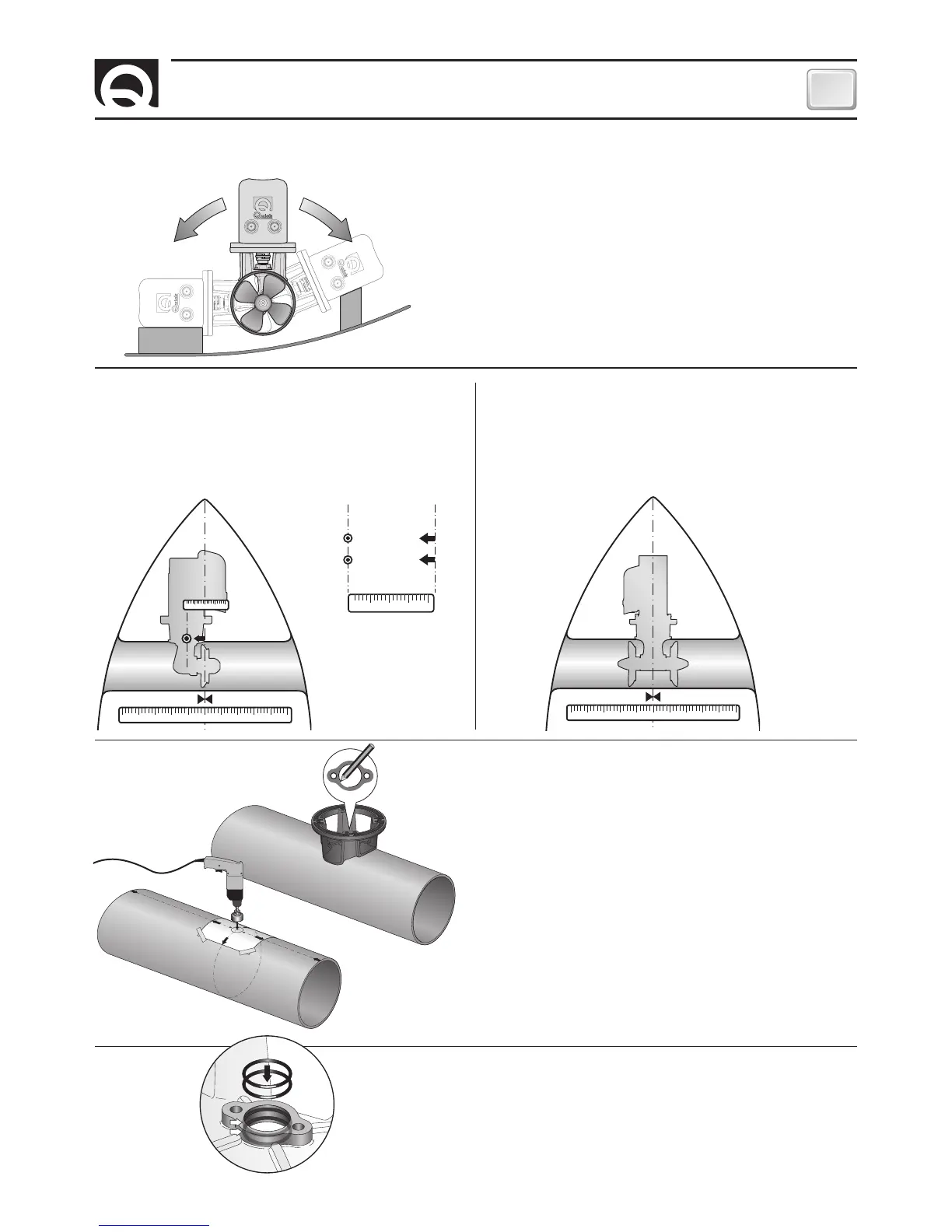

To position the thruster in the tube, find the half-way point

and move to the value shown (

to the right or to the left see

NOTE page 23

) in the table below so that the propeller is

positioned exactly half way along the internal length of the

tunnel.

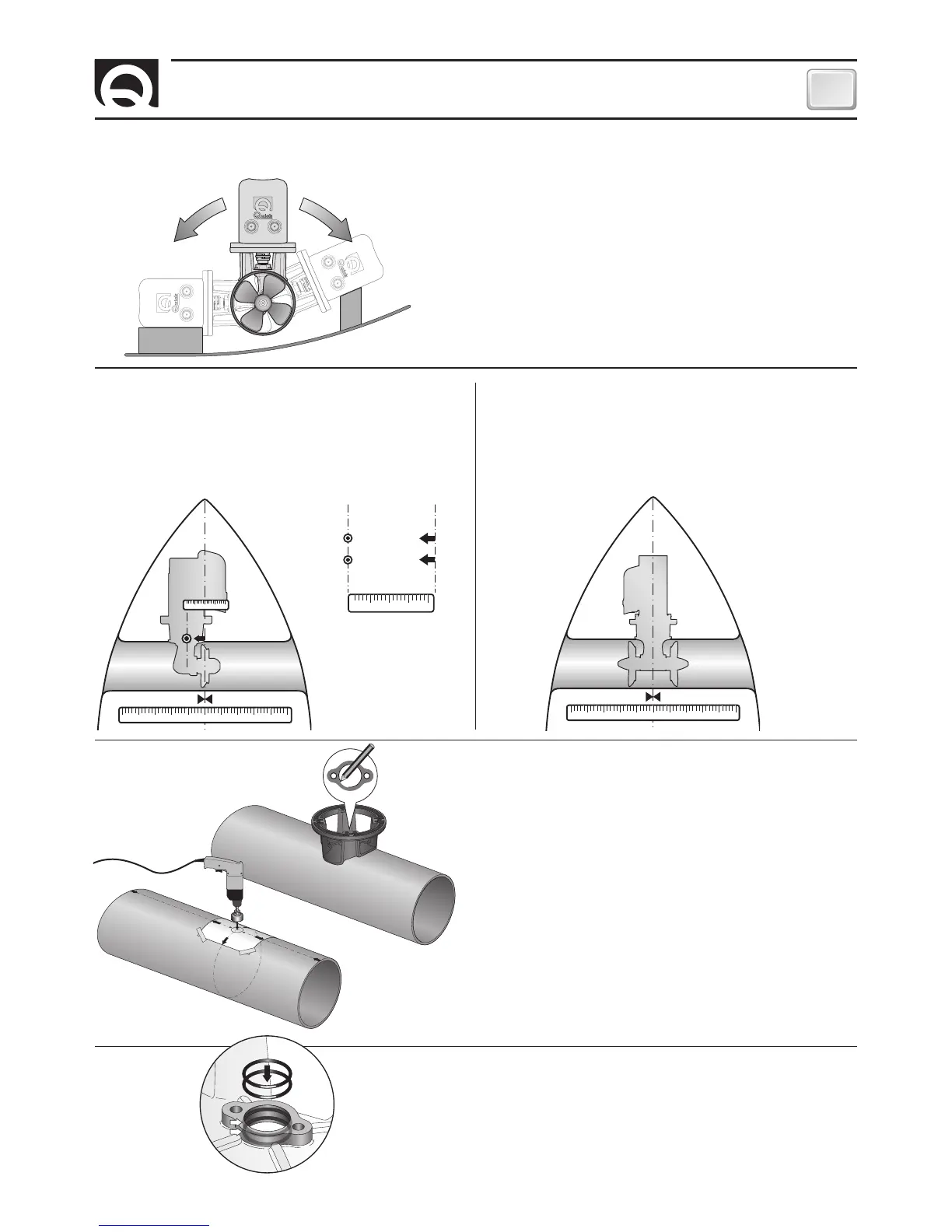

• Use the flange to mark the centre of the holes on the tube.

• Fix the drilling template on the reference points, making

sure they are aligned with precision at the half-way point of

the tube.

N.B. All holes must be exactly aligned with the half-way point

of the tunnel, since tolerance between propeller and tunnel

is minimal.

• Take care that there are no resin residues in the contact

area between flange and tube; this could cause misalign

-

ment. Any resin residues and any other hindrance to correct

contact must be removed by sandpaper.

• The thruster can be installed at any angle within 90° from

vertical.

• If the electric motor is positioned of necessity at an angle

of more than 30° from vertical, a special support must be

constructed.

10 2 3 4 5 6 7 8 9 10

10 2 3 4

• Insert two o-rings into the special seats inside the flange.

10 2 3 4 5 6 7 8 9 10

• To position the thruster in the tube, find the half-way point.

SINGOL PROPELLER DOUBLE PROPELLER

Loading...

Loading...