A

C

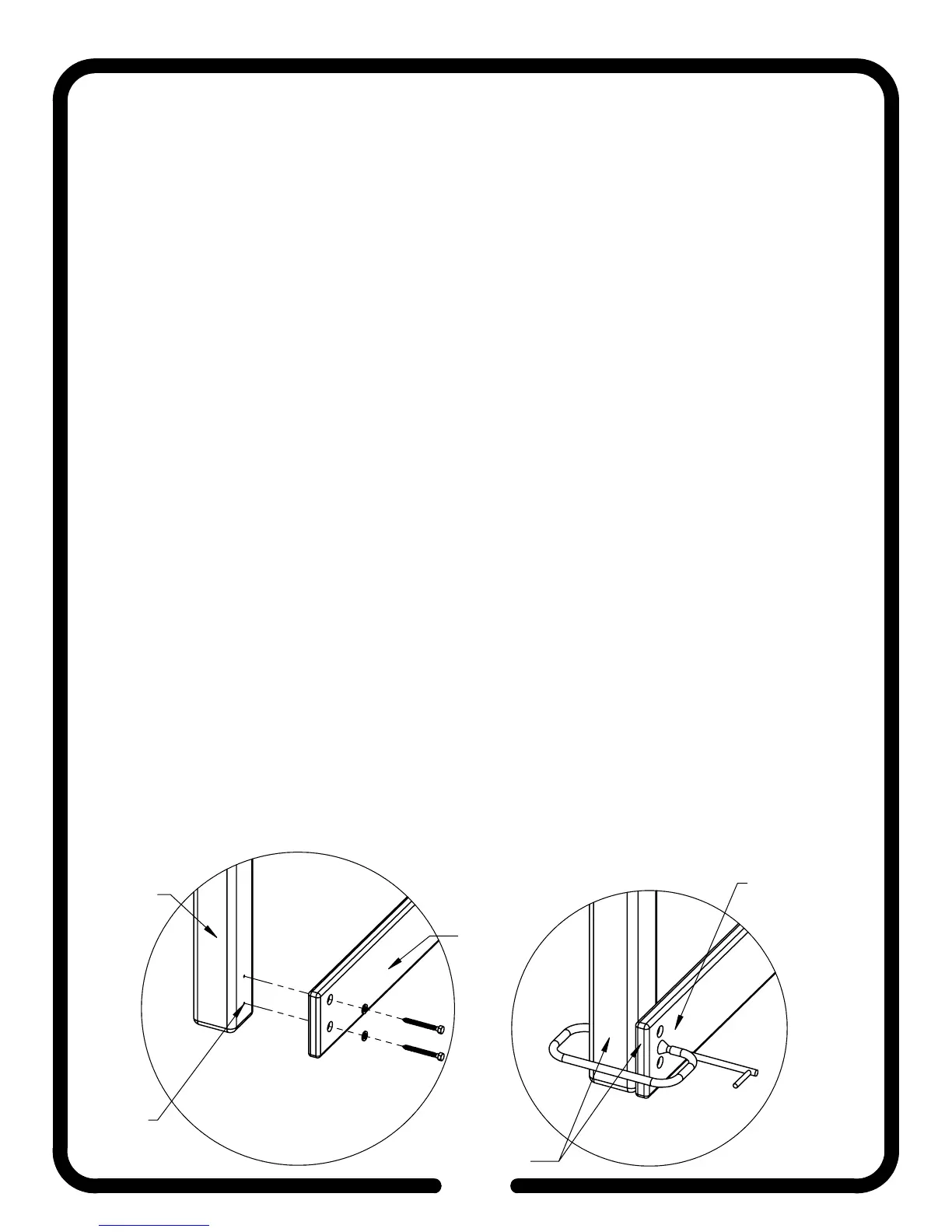

UPRIGHT

FACIA

PILOT

HOLES

DETAIL A

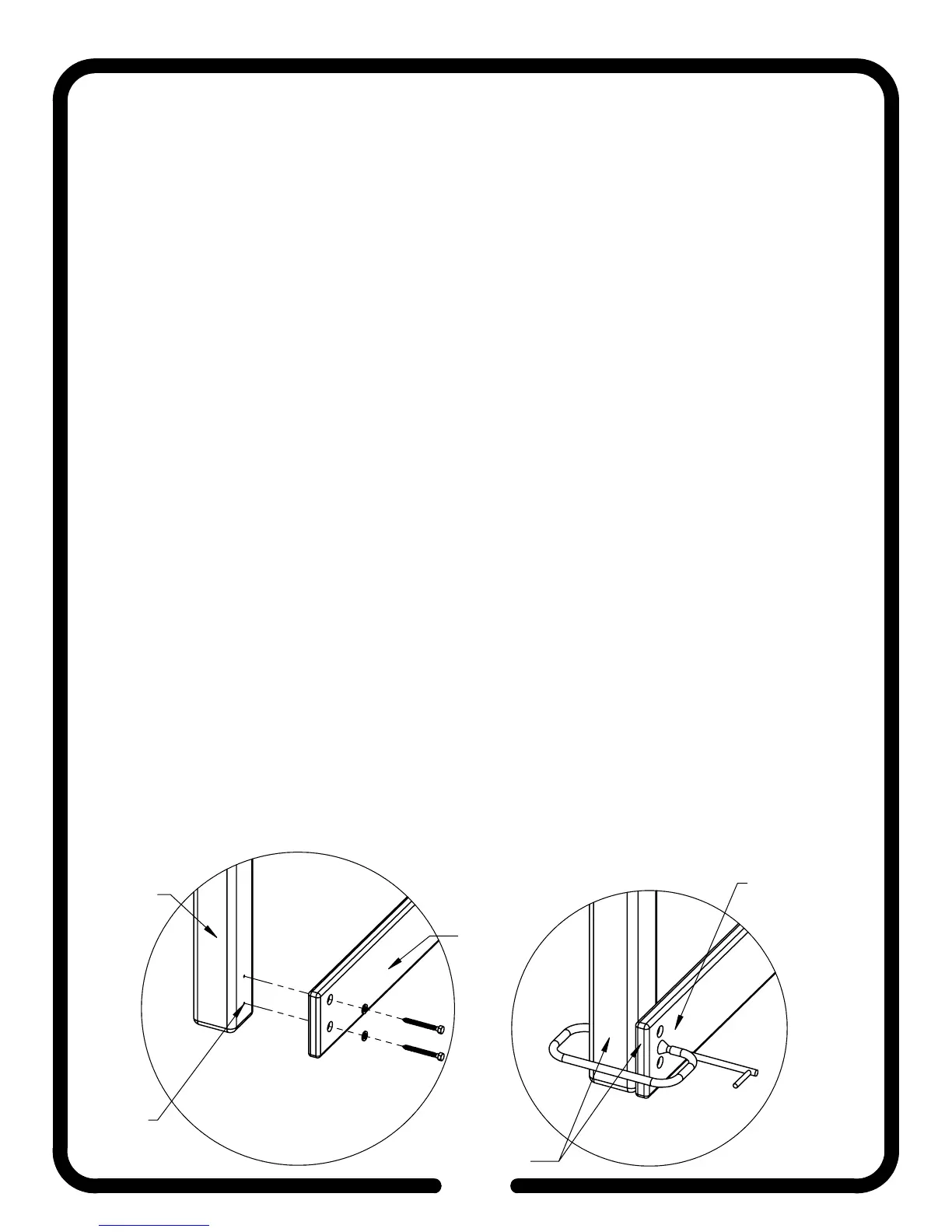

FACES MUST

BE FLUSH

USE FACIA AS

A GUIDE FOR

PRE-DRILLING

HOLES

DETAIL B

8.

Check

the C-Links on the chain to ensure they are securely closed. Tighten with a crescent wrench as

needed.

9.

On a yearly basis,

we recommend that you coat your play system with a sealant or preservative. You may

also want to spot sand areas before sealing. Be sure that the sealant you select is non-toxic and child safe.

10.

When you are ready to dispose of your play set,

make sure all metal, plastic and wood components are

disposed of in accordance with local waste ordinances.

Helpful Installation Hints

*NOTE: Refer to these assembly tips throughout the entire installation process.

1.

After thoroughly reading all information and properly locating your play system site, carefully

unpack parts. As you unpack your play system, keep the parts list handy and become familiar with each

part before beginning assembly. Remember that a little extra time spent familiarizing yourself with the parts

and instructions before you begin will help avoid mistakes and save you time later.

2.

Group

both wood and non-wood parts together in accordance to each Step of this assembly manual. Doing

this now, will help you quickly locate parts and assemble the set with more ease.

3.

Locate

an area to sort your hardware in accordance to each step. A solid surface, such as the empty boxes,

are best to ensure you do not lose any hardware.

4.

Before

starting each Step, thoroughly read the entire instructions to ensure all information is understood.

Pay special attention to the orientation of each part, details & notes, and proper usage of hardware. Each

piece of hardware is required for a certain part of the assembly.

5.

Certain

Steps of the assembly are best performed on a hard flat surface to ensure proper and accurate

assembly.

6.

All

Lag Bolts must have pre-drilled holes 2" deep (as shown in Detail A). Use a 1/8" drill bit for all 1/4" and

5/16" Lag Bolts and use a 1/4" drill bit for all 3/8" Lag Bolts. Lag Bolts can be difficult to drill into knot holes.

Pre-drilling pilot holes will help to prevent the Lag Bolts from breaking. Refer to "Commonly Asked Questions"

on page 7 for more information about Lag Bolts.

7.

All

#14 Phillips Pan Head Tap Screws must have pre-drilled holes 1/2" deep. Use a 1/8" drill bit.

8.

Use

a clamp to secure Facias flush to the Uprights and use holes in facia as a guide for placing Lag

Bolt Pilot Holes (as shown in Detail B).

9.

Verify

Facias are flush with Uprights.

10.

Check

assembly periodically to ensure the set is level and all facias are square to the uprights.

11. If a gap occurs between boards when inserting Screws or Lag Bolts, back out hardware and apply pressure to

the top board while reinserting hardware in the same hole.

6

Loading...

Loading...