OTHER FEATURES

Control Operation During a Power Failure

In the event of a power failure, the valve will keep track of the time and day for 48 hours. The programmed settings

are stored in a non-volatile memory and will not be lost during a power failure. If power fails while the unit is in

regeneration, the valve will finish regeneration after power is restored. If the valve misses a scheduled regeneration

due to a power failure, it will queue regeneration at the next regeneration time once power is restored.

Safety Float

The brine tank is equipped with a safety float which prevents your brine tank from overfilling as a result of a

malfunction such as a power failure.

New Sounds

You may notice new sounds as your water softener operates. The regeneration cycle lasts approximately 2 hours.

During this time, you may hear water running intermittently to the drain.

Manual Bypass

In the case of emergency, such as an overflowing brine tank, you can isolate your water softener from the water

supply using the bypass valve located at the back of the control. To resume soft water service, open bypass valve by

rotating the knobs counterclockwise.

MAINTENANCE

Adding Salt

Use only high grade water softener salt. Check the salt level monthly. It is important to ALWAYS maintain the salt

level above the water level. To add salt, simply remove the salt tank lid and add the salt directly into the brine tank.

Be sure the brine well cover is on and fill only to the height of the brine well. The salt tank should never be empty.

Prevent Salt Bridging

Humidity or wrong type of salt may create a cavity between the water and the salt. This action, known as “bridging”,

prevents the brine solution from being made, leading to your water supply being hard. If you suspect salt bridging,

pour some warm water over the salt to break up the bridge. Allow four hours to produce a brine solution, then

manually regenerate the softener. This should always be followed up by allowing the unit to use up any remaining

salt and then thoroughly cleaning out the brine tank.

Care of Your Softener

To retain the attractive appearance of your new water softener, clean occasionally with mild soap solution. Do not

use abrasive cleaners, ammonia or solvents.

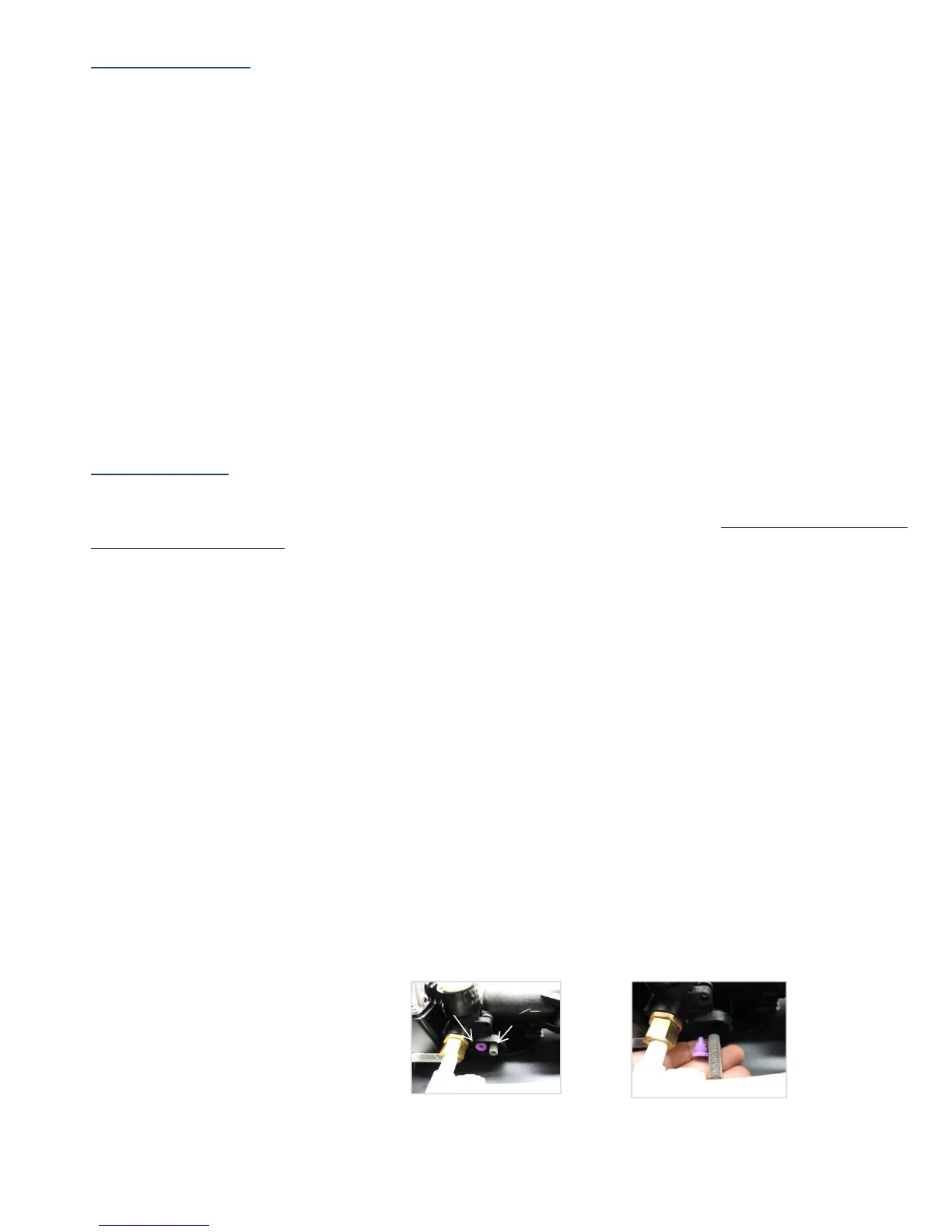

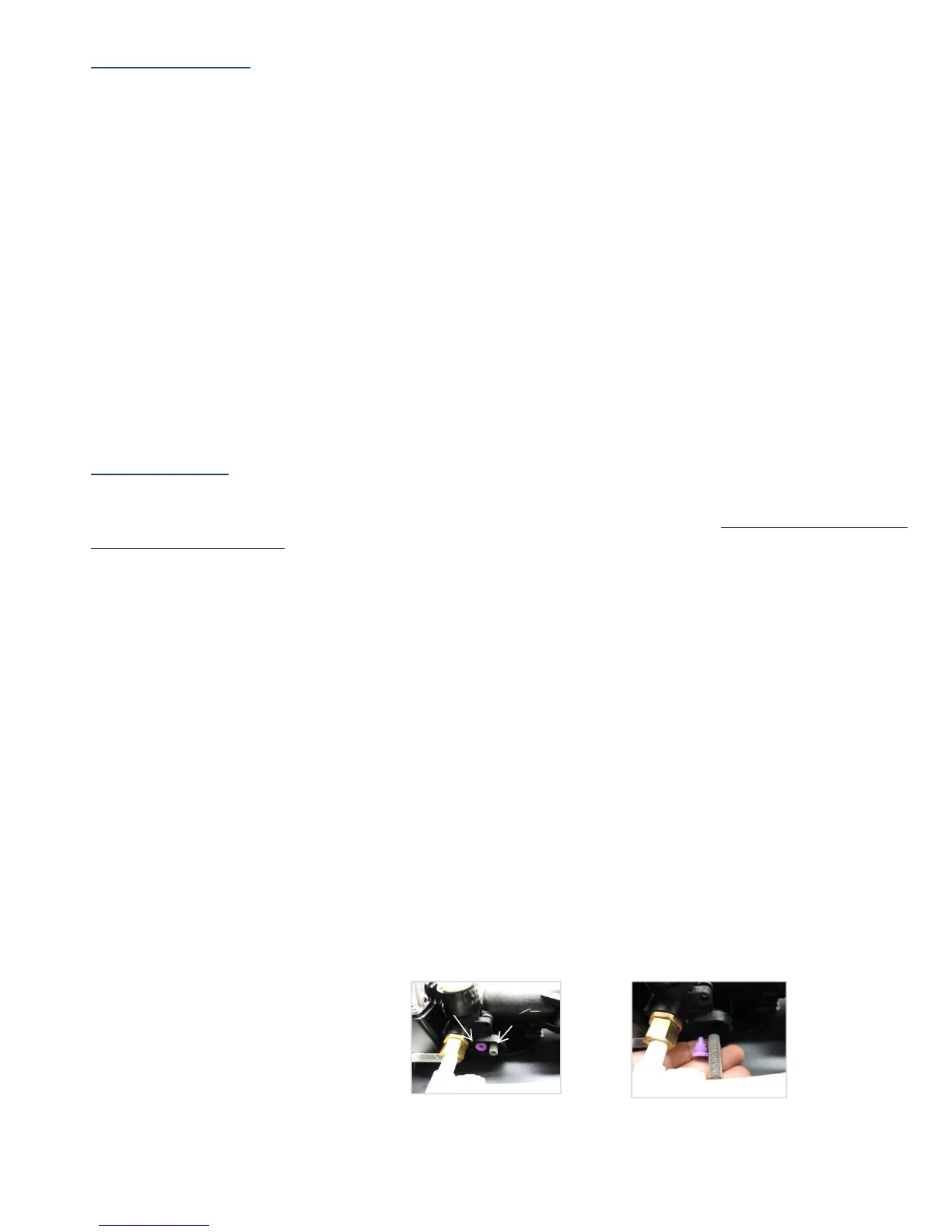

Cleaning the Injector Assembly

Sediment, salt and silt will restrict or clog the injector. A clean water supply and pure salt will prevent this from

happening. The injector assembly is located on the right side of the control valve. This assembly is easy to clean.

Shut off the water supply to your softener and reduce the pressure by opening a cold soft water faucet. Using a

screwdriver, remove the two screws holding the injector cover to the control valve body. Carefully remove the

assembly and disassemble as shown below. The injector orifice is removed from the valve body by carefully turning

it out with a large screwdriver. Remove the injector throat the same way. Carefully flush all parts including the

screen. Use a mild acid such as vinegar to clean the small holes in the orifice and throat.

Reassemble using the reverse procedure.

Loading...

Loading...