GENERAL

Power Capacity Ratings

Loudspeaker Limitations and Failure Modes

Because there are no 'standard' musical programs with which

to test the power capacity of a loudspeaker, laboratory rating

methods have been

developed.

The purpose of power capacity

ratings is two-fold: to provide a

repeatable,

Industry-standard

basis for comparisons, and to achieve a rating method that

is representative of actual-use conditions. Standard test

signals are repeatable, and provide for reliable comparative

measurements, but test signal evolved to simulate 'typical'

audio programs cannot emulate typical audio programs or

conditions of use by definition. Power capacity ratings are

not absolute, when the program material is other than the

test signal used for the rating. Knowledge of the power

capacity rating method and of practical loudspeaker limitations

can prevent unforeseen failures, rewarding the informed with

years of trouble-free product use.

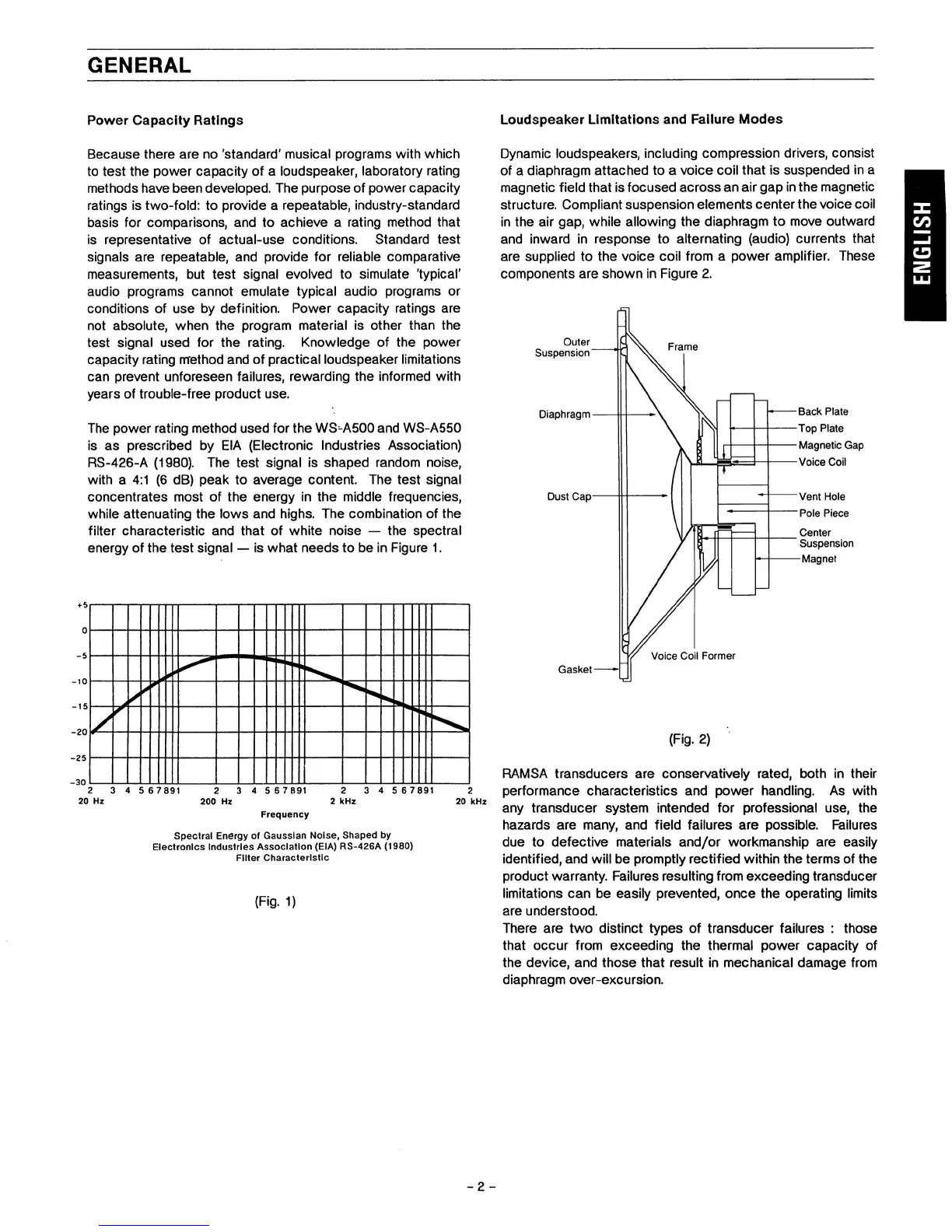

The power rating method used for the

WS^A500

and WS-A550

is as prescribed by

EIA

(Electronic Industries Association)

RS-426-A (1980). The test signal is shaped random noise,

with a 4:1 (6 dB) peak to average content. The test signal

concentrates most of the energy in the middle frequencies,

while attenuating the lows and highs. The combination of the

filter characteristic and that of white noise — the spectral

energy of the test signal — is what needs to be in Figure 1.

0

-5

10

-15

20

25

in

2

20 Hz

3 4 5 67891

2 3

200 Hz

4 5 67891

Frequency

2

2 kHz

3 4

5

67891 2

20 kHz

Spectral Energy of Gaussian Noise, Shaped by

Electronics Industries Association (EIA) RS-426A (1980)

Filter Characteristic

(Fig.

1)

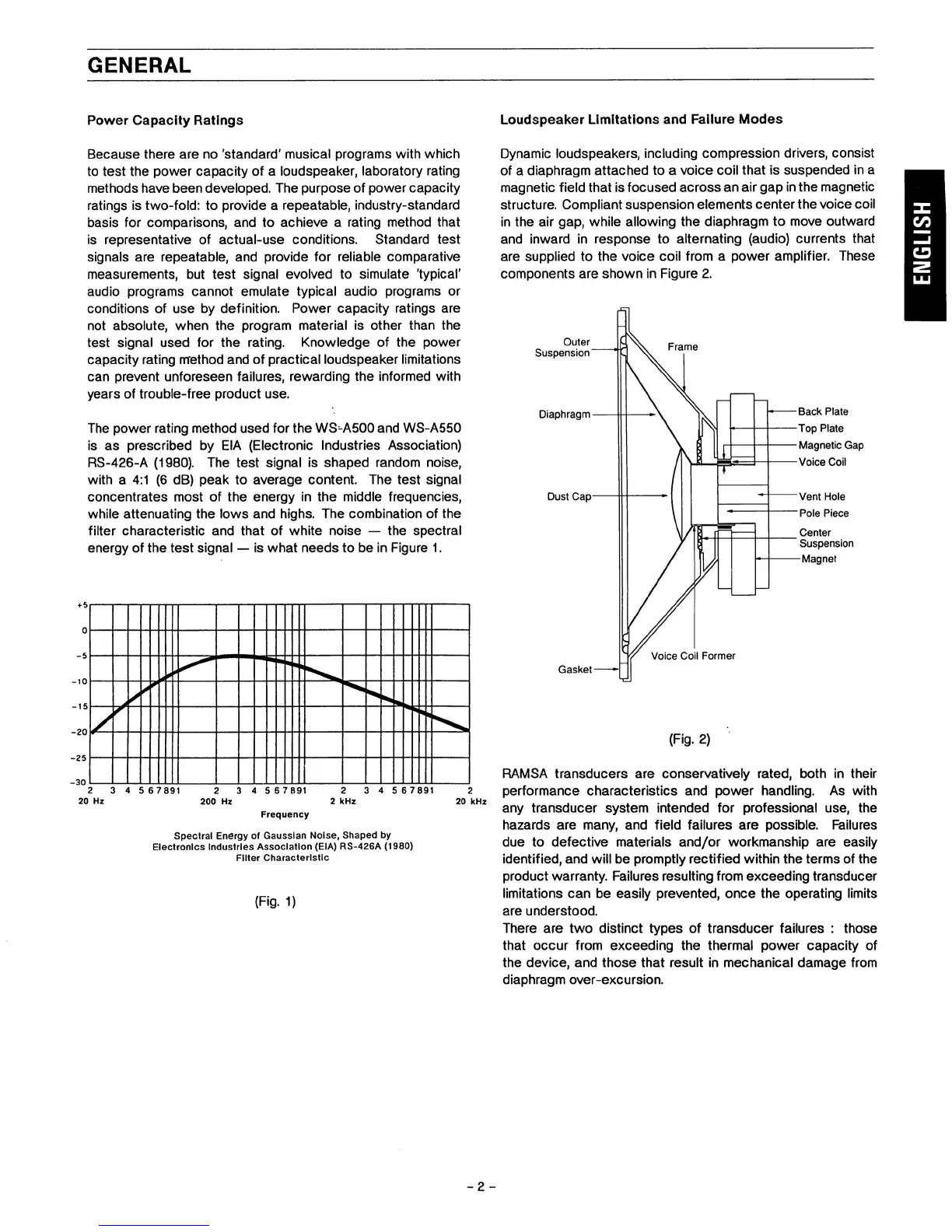

Dynamic loudspeakers, including compression drivers, consist

of a diaphragm attached to a voice

coll

that is suspended in a

magnetic

field

that

is

focused across an air gap

in

the magnetic

structure. Compliant suspension elements center the voice coil

in the air gap, while allowing the diaphragm to move outward

and inward in response to alternating (audio) currents that

are supplied to the voice coil from a power amplifier. These

components are shown in Figure 2.

Outer

Suspension

Diaphragm

Dust Cap

Frame

Back Plate

Top Plate

Magnetic Gap

Voice Coil

Vent Hole

Pole Piece

Center

Suspension

Magnet

Voice Coil Former

Gasket

(Fig.

2)

RAMSA transducers are conservatively rated, both in their

performance characteristics and power handling. As with

any transducer system intended for professional use, the

hazards are many, and field failures are possible. Failures

due to defective materials and/or workmanship are easily

identified,

and will be promptly rectified within the terms of the

product warranty. Failures resulting from exceeding transducer

limitations can be easily prevented, once the operating limits

are understood.

There are two distinct types of transducer failures : those

that occur from exceeding the thermal power capacity of

the device, and those that result in mechanical damage from

diaphragm over-excursion.

Loading...

Loading...