Thermal Power Limits

The voice

colls

of RAMSA professional loudspeakers are

designed to operate at very

high

temperatures before risk

of a 'burnout' failure. However, It is useful to remember that

the vast majority of the power in a loudspeaker Is converted to

heat, with only a small percentage of the energy converted into

acoustic power. Because the voice coil is operating in an air

gap,

precious little heat Is conducted away through the cone

and suspension elements. Some of the heat is radiated to the

transducer's metal parts, but the majority of the cooling comes

from air circulation.

The outward and inward movement of the diaphragm creates

air movement to cool the voice

coil,

without which the coil

would be subject to greater heating and premature thermal

failure.

The EIA RS-426A test signal contains sufficient low

frequency information to create air movement across the voice

coil that is typical of program material use conditions, but

the weighting precludes high power at low frequencies that

could

induce

mechanical failures by exceeding transducer

displacement limits. Power ratings based upon the EIA

RS-426A rating method are, therefore, appropriate thermal

power limits for program use conditions.

Both the WS-A500 (operated with its internal passive

crossover) and WS-A550 can easily sustain their (RS-426A)

thermal rated power, but can be damaged by exceeding

mechanical displacement limits (currently, there are no

displacement-limited power capacity rating methods). When

the WS-A500 Is

bi-amplified,

special precautions are

necessary to protect the HF transducer from damage.

Mechanical Power Limits

A loudspeaker imparts sound pressure to the air, alternately

compressing and rarefying by outward and inward diaphragm

movement for each Hz of audio information. (One Hertz is

a complete cycle of diaphragm movement, beginning from rest

position to the outward peak, returning through the rest position

to the inward peak, and finally returning outward to the rest

position.) The rate at which the diaphragm completes cycles is

the frequency, while the energy produced is proportional to the

product of frequency squared and diaphragm displacement.

For constant frequency-energy output

(flat

power response),

direct-radiating diaphragms must quadruple

In

displacement

for each halving of frequency.

All transducers have mechanical diaphragm displacement

limits.

Depending upon the transducer's design, the limits are

reached when the voice coil is driven out of the magnetic

field,

or when the suspension can no longer stretch to

allow diaphragm movement. In the former case, the driving

electromagnetic force diminishes as the voice

coll

begins to

leave the air gap. Under the conditions, it

Is

unlikely that the

transducer would be easily damaged through over-excursion,

as the driving force Is reduced before the suspension limits are

reached.

The LF transducer of the model WS-A500 is of this

type.

With other design approaches, the available voice coil travel

and electromotive strength can be sufficient to exert damaging

forces upon the suspension components. Transducers

intended for extended bass or subwoofer applications

generally feature very long voice coils and high dynamic forces

to enable large volume displacement. With these 'long-throw'

devices, physical damage is possible at electrical power levels

that are less than the thermal power capacity rating of the

speaker, depending upon the

frequency-magnitude

of the audio

signal.

The transducer in the WS-A550 subwoofer system is

typical of a class of devices with these characteristics.

Signal Processing Requirements

The WS-A500 and WS-A550 loudspeaker systems are

capable of high performance in demanding professional-use

application. Both systems are highly-specialized devices, and

have been optimized for operation within specific frequency

ranges. To achieve optimal performance, the WS-A500 and

WS-A550 should be used with the RAMSA model WS-SP2A,

which provides band-pass signal processing for both speaker

systems.

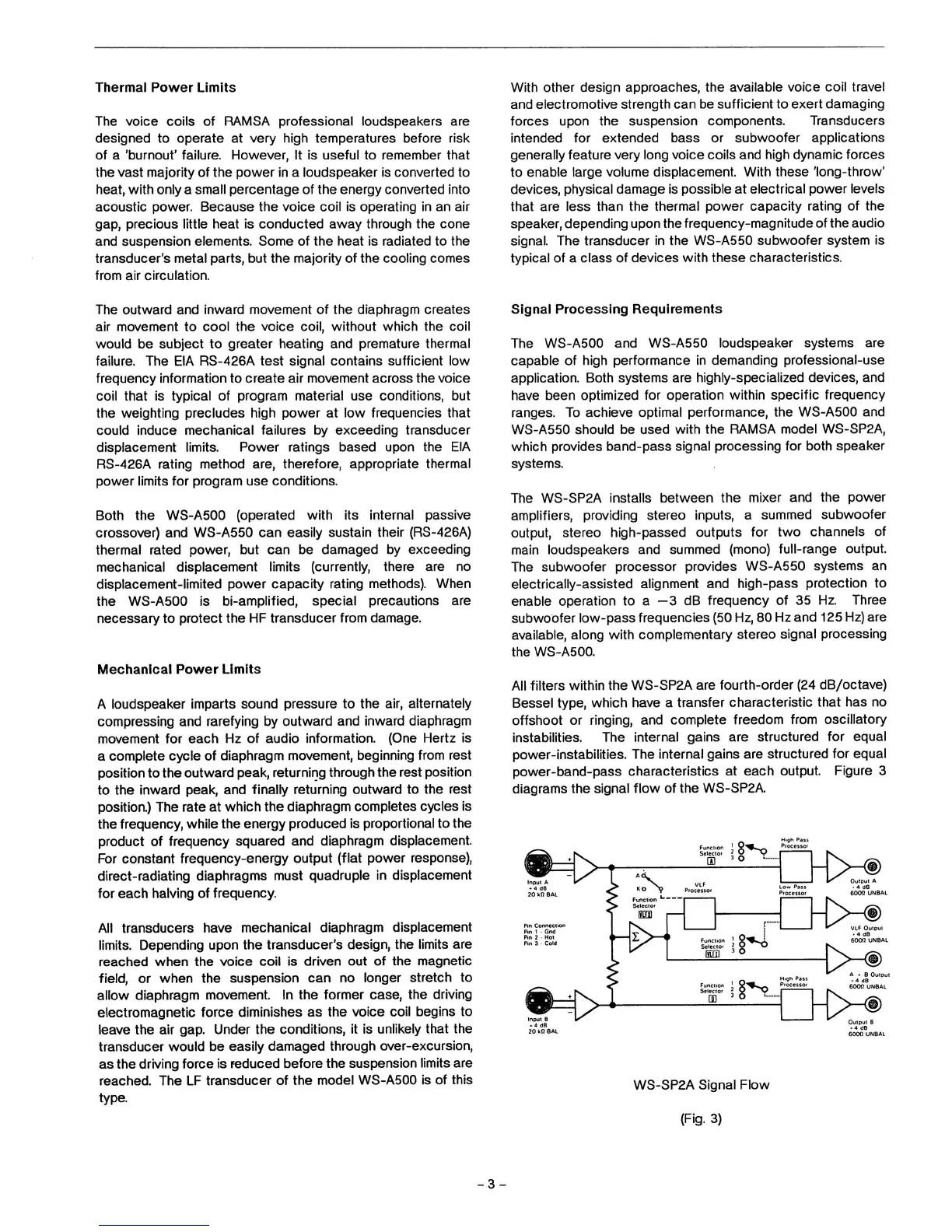

The WS-SP2A installs between the mixer and the power

amplifiers, providing stereo

Inputs,

a summed subwoofer

output, stereo high-passed outputs for two channels of

main loudspeakers and summed (mono) full-range output.

The subwoofer processor provides WS-A550 systems an

electrically-assisted alignment and high-pass protection to

enable operation to a —3 dB frequency of 35 Hz. Three

subwoofer low-pass

frequencies

(50 Hz, 80 Hz and

125

Hz) are

available, along

with

complementary stereo signal processing

the WS-A500.

All filters within the WS-SP2A are fourth-order (24 dB/octave)

Bessel type, which have a transfer characteristic that has no

offshoot or ringing, and complete freedom from oscillatory

instabilities. The internal gains are structured for equal

power-instabilities. The internal gains are structured for equal

power-band-pass characteristics at each output. Figure 3

diagrams the signal

flow

of the WS-SP2A.

8^o

i

Processc

Sei

^M§)

Œ

©

X

d

dB

dii

soon

uNBAi

20 Ml BAL

-T>M§)

©

EFJ

>*

Pin Conned

LF Output

Gnd

Pin

2 Hot

6001) UNBAL

Pin 3 - Cold

r>-<§)

fycm

©

B

Outp

4 dB

"^0

Func

6000

UNBAL

Inrjuf

B

<

Selec

V-®

m

©

B

Output B

B

4

dB

20

kit SAL

600(1 UNBAL

WS-SP2A Signal Flow

(Fig.

3)

-3-

Loading...

Loading...