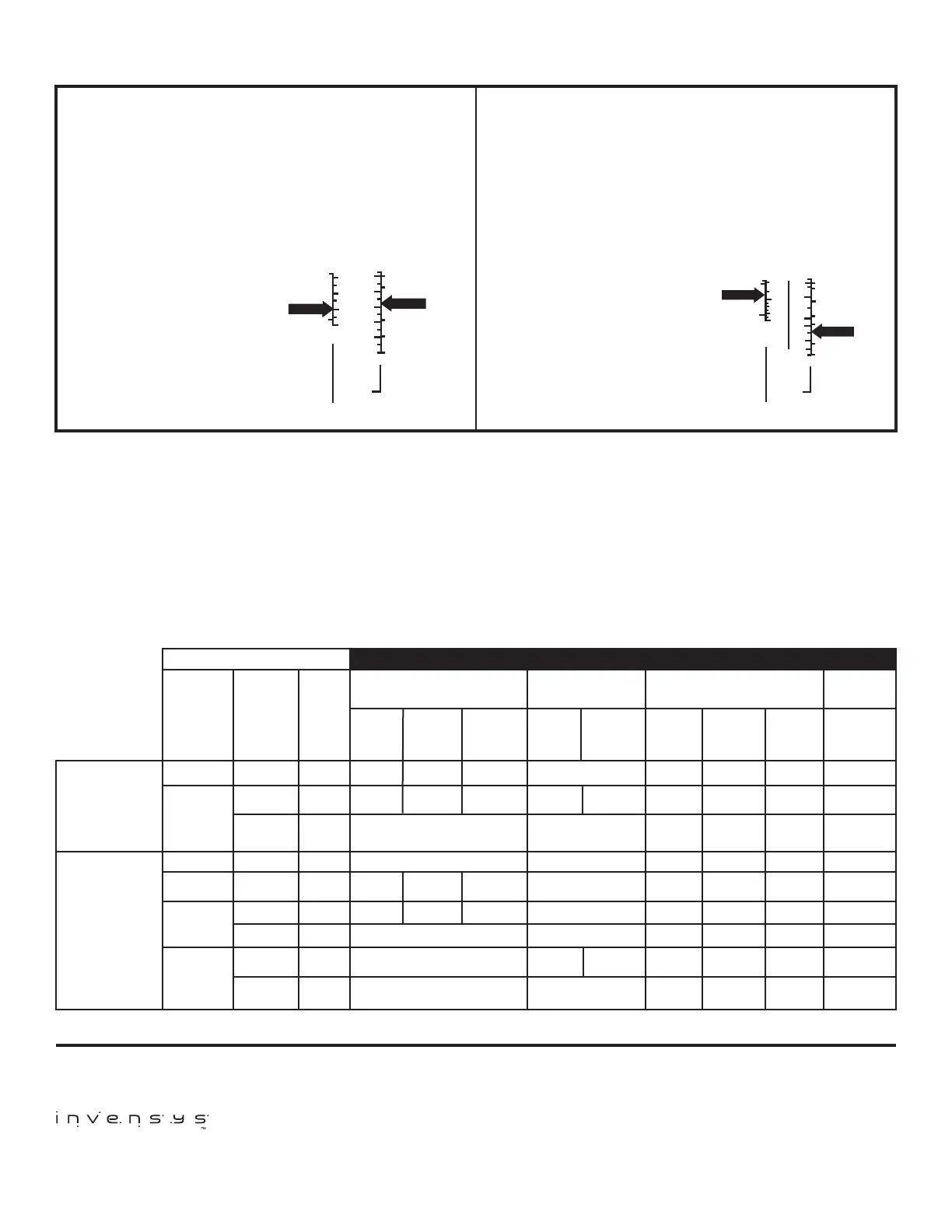

ADJUSTMENT EXAMPLES (See Control Settings and Adjustment P.3)

CLOSE ON RISE CONTROLS with Automatic

reset 010 and 020; 016 terminals 2-3

The scaleplate directly indicates the cut-in and differential.

The cut-out is calculated by subtracting the differential from

the cut-in:

1) Adjust the range screw

until the scale pointer

indicates the desired

cut-in setting.

2) Adjust the differential

screw until the scale

pointer indicates the

desired differential

setting. The cut-out

setting equals the cut-in

setting, less the

differential.

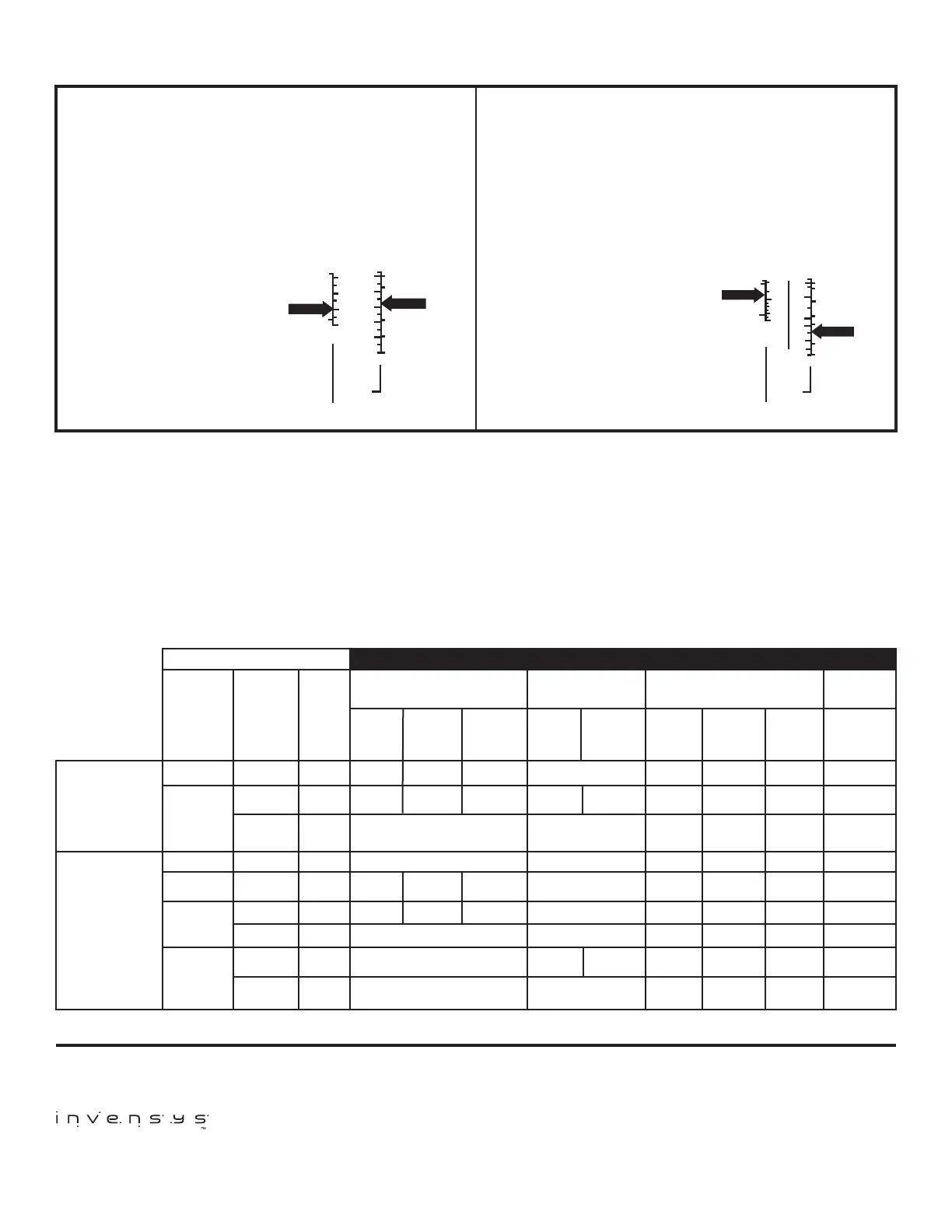

OPEN ON RISE with Automatic reset

011

The scaleplate directly indicated the cut-out and differential.

The cut-in is calculated by subtracting the differential from

the cut-out:

1) Adjust the range screw

until the scale pointer

indicates the desired

cut-out setting.

2) Adjust the differential

screw until the scale

pointer indicates the

desired differential

setting. The cut-in

setting equals the cut-out

setting, less the

differential.

EXAMPLE

Cut In

Differential

Cut Out

36 - 20 = 16

Differential

Cut In

CLOSES ON PRESSURE RISE

CUT OUT IS

CUT IN

MINUS

DIFFERENTIAL

20

36

20

30

40

10

10

20

40

60

80

100

3.0

2.0

1.0

KG.

LBS.

0

1.0

4.0

5.5

7.0

KG.

LBS.

EXAMPLE

Cut Out

Differential

Cut In

360 - 120 = 240

Differential

Cut Out

OPEN ON RISE OF PRESSURE

CUT IN IS

CUT OUT

MINUS

DIFFERENTIAL

120

360

40

100

150

150

250

350

450

1.0

4

KG.

LBS.

10

15

20

30

KG.

LBS.

LOW PRESSURE CHECK

Low pressure controls can be preset by using a container of re-

frigerant and a gauge set. Use a continuity meter to indicate the

closing and opening of the switch. Adjust the control to the de-

sired settings; pressurize the control while adjusting the settings.

Low pressure settings can be rechecked when the unit is running

by connecting a gauge to the section line service valve. Close the

liquid line valve and allow the system to pump down, observing

the low switch opening (or closing). Open the liquid line valve and

allow the pressure to increase, observing the high switch closing

(or opening). Adjust the settings as necessary.

HIGH PRESSURE CHECK

High pressure control settings can be checked by selectively dis-

connecting various stages of fans or by blocking the air ow on

air cooled condensers. On water cooled condensers, reduce or

shut off the water ow while observing the cut-out and adjust as

required.

CAUTION: These checks must be for a brief time only.

LOW

PRESSURE

HIGH

PRESSURE

Pressure

Range

P.S.I.G.

(Inches

Mercury

Vacuum)

(12”) to 50

(10”) to 100

50 to 150

100 to 250

100 to 400

150 to 450

Differential

P.S.I.

5 to 35

10 to 40

Manual*

Reset

10 to 40

20 to 100

40 to 150

17 Fixed

40 to 150

Manual**

Reset

Lowest

Event

P.S.I.G.

(Inches

Mercury

Vacuum)

(20”)

(20”)

(20”)

10

0

0

83

0

110

SPECIFICATIONS

O10 O11 O16 O20

SPST-Opens Low SPST-Opens High SPDT-Opens High or Low DPST-

Opens Low

Male

Flare

O16-120

O16-107

O16-585

-

-

O16-5870

-

O16-503

O16-209

36”

Capillary

with

Flare Nut

O16-557

O16-527

-

O16-166

-

O16-108

O16-142

-

-

48”

Capillary

with

Flare Nut

-

-

O16-261

-

O16-593

-

-

-

O16-200

36”

Capillary

with

Flare Nut

O20-7002

O20-7004

-

-

-

O20-7006

-

-

-

36”

Capillary

with

Flare Nut

Male

Flare

48”

Capillary

with

Flare Nut

36”

Capillary

with

Flare Nut

Male

Flare

O10-1401

O10-1831

Use O16

Use O16

O10-1807

O10-1894

Use O16

Use O16

Use O16

O10-1402

O10-1483

-

O10-2054

O10-1842

O10-1093

O10-2000

-

O11-1799 O11-3099

Use O16

Use O16

Use O16

Use O16

Use O16

011-1713

Use O16

Use O16

011-1711

* Locks on Pressure decrease. Pressure must rise approx. 10 PSI to be reset.

** Locks on pressure increase. Pressure must stop approx. 40 PSI to be reset.

191 E. North Avenue

Carol Stream Illinois 60188 USA

Customer Service Telephone 1.800.304.6563

Customer Service Facsimile 1.800.426.0804

HVACCustomerService@Invensys.com

Invensys™, Robertshaw

®

, Ranco

®

, and Eliwell are trademarks

of Invensys plc., its subsidiaries and/or affiliated companies. All

other brands mentioned may be the trademarks of their respective

owners.

www.Uni-Line.com

www.InvensysControls.com

©2013 Invensys

1515064 Rev C

For Technical Service

Telephone 1.800.445.8299

Facsimile 1.630.260.7294

TechnicalService@Invensys.com

Loading...

Loading...