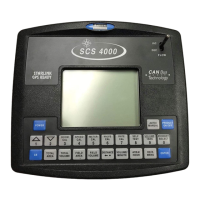

Initial Startup & Console Programming Page: 35 Reset Console Memory Procedure to reset the SCS console's internal memory to initial programming screens.

Units Setting the measurement units (US Acres, Hectares, etc.) for the console.

Valve Type Selecting the type of control valve used with the SCS console.

Valve Cal Programming the valve calibration number to adjust control valve response.

Rate Cal Entering the target application rate for product application.

Speed Cal Recommends initial speed calibration values and procedures for refining them.

Boom Cal Programming boom section widths for accurate application.

Edit Mode Detailed explanation of how to enter and use Edit mode for programming.

Calibration Keys How calibration keys are used to program and calibrate the system.

Boom Cal Specific instructions for accessing and entering boom widths.

Speed Cal Instructions for accessing speed calibration.

Meter Cal Instructions for accessing meter calibration for different product types.

Valve Cal Detailed explanation of valve calibration and its parameters.

Rate Cal Explanation of the rate calibration function.

Self Test How to use the self-test mode for checking the product control system.

Function Keys Explains the use of function keys for displaying application information.

Area;Hour Estimates area coverage based on current speed and boom operation.

Data Menu Accesses the SCS Data Menu for further settings.

Tank Volume Displays current volume remaining in the tank or bin.

Self Test Mode Simulates speed for testing the system without the vehicle moving.

Decimal Shift Feature to increase system accuracy at low application rates.

Data Menu Page: 45 Serial Submenu Contains options related to serial communication and data logging.

Data Logger Enables or disables data logging and specifies conditions for its use.

Trigger Value Determines how often data is sent to the serial port.

Boom Select Assigns products to individual boom sections for application.

Off Rate % Sets acceptable percentage deviation for application rate and triggers alarms.

PWM High Offset Sets the maximum desired RPM or hydraulic output for PWM control valves.

PWM Low Offset Sets the minimum desired RPM or hydraulic output for PWM control valves.

Low Flow Limit Controls valve to low flow limit and activates alarm if volume/minute falls below assigned limit.

Low Tank Activates low level alarm when tank volume falls below a defined level.

Valve Delay Sets delay between console controlling flow rate and booms being turned on.

Valve Cal 2 Fine-tunes control valve response for PWM mode applications.

Pressure Displays current PSI, kPa, or BAR pressure readings.

Agitator Enables or disables a chemical agitator.

PWM Output Indicates PWM valve position for fine-tuning offsets.

Contrast Adjusts screen contrast for readability.

Days Wait Sets delay before console enters low power mode and loses time settings.

Data Lock Prohibits calibration value entry without a data lock code.

Ratio Rate Enables or disables ratio rate application mode for multiple products.

Zero Speed Shutoff Shuts off product control if speed drops below a set limit in automatic mode.

CAN Submenu Options for checking CAN communication and node status.

Setup Steps to set up the data logging system with a compact flash card.

Console Calibration Page: 59 Speed Cal Recommends initial speed calibration values and procedures for refining them.

Boom Cal Calculating and programming boom section widths for liquid sprayers.

Meter Cal Finding and copying flow meter calibration numbers.

Valve Cal Programming valve calibration numbers for control valve response.

Break Point Digit Sets percentage from target rate for slower turn to avoid overshoot.

Dead-Band Digit Allowable difference between target and actual application rate.

Rate Cal Programming target application rate and checking gate opening capability.

Spinner RPM Setting up spinner RPM control and associated calibration values.

Flow Cal Sets system response to rate control inputs based on flow meter data.

Boom Cal Entering boom widths for granular applications.

Spreader Constant Calculating and verifying the spreader constant for granular applications.