-_.

-

.

_. .

.___-

----

.-.__

x..

--.

-

..-_._.

_-.

_-..

-..

.

--..

.

..------.--...-.---.--.

.-

.-..

.-

.

.

.

_

-.

.

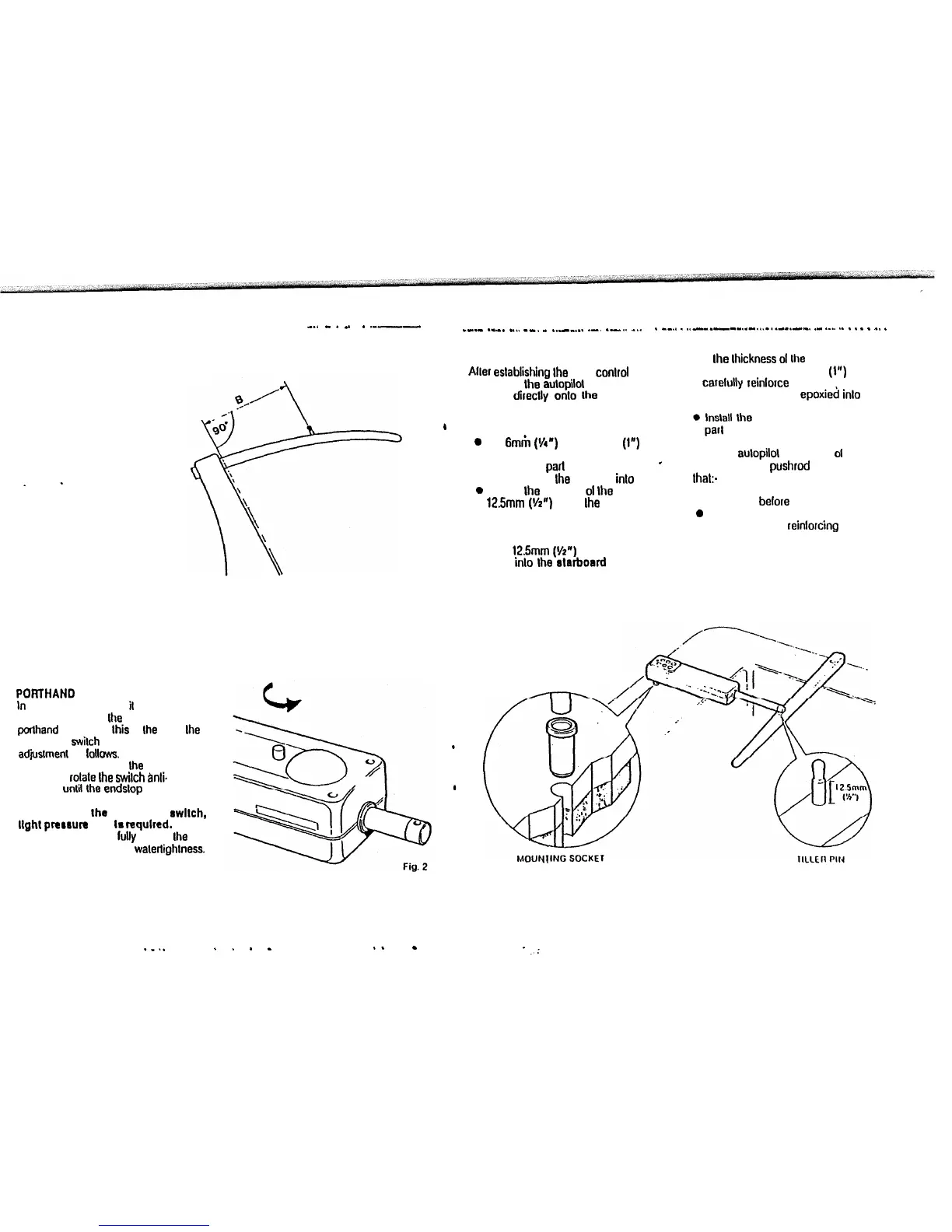

SLOPING RUDDERSTOCK

I

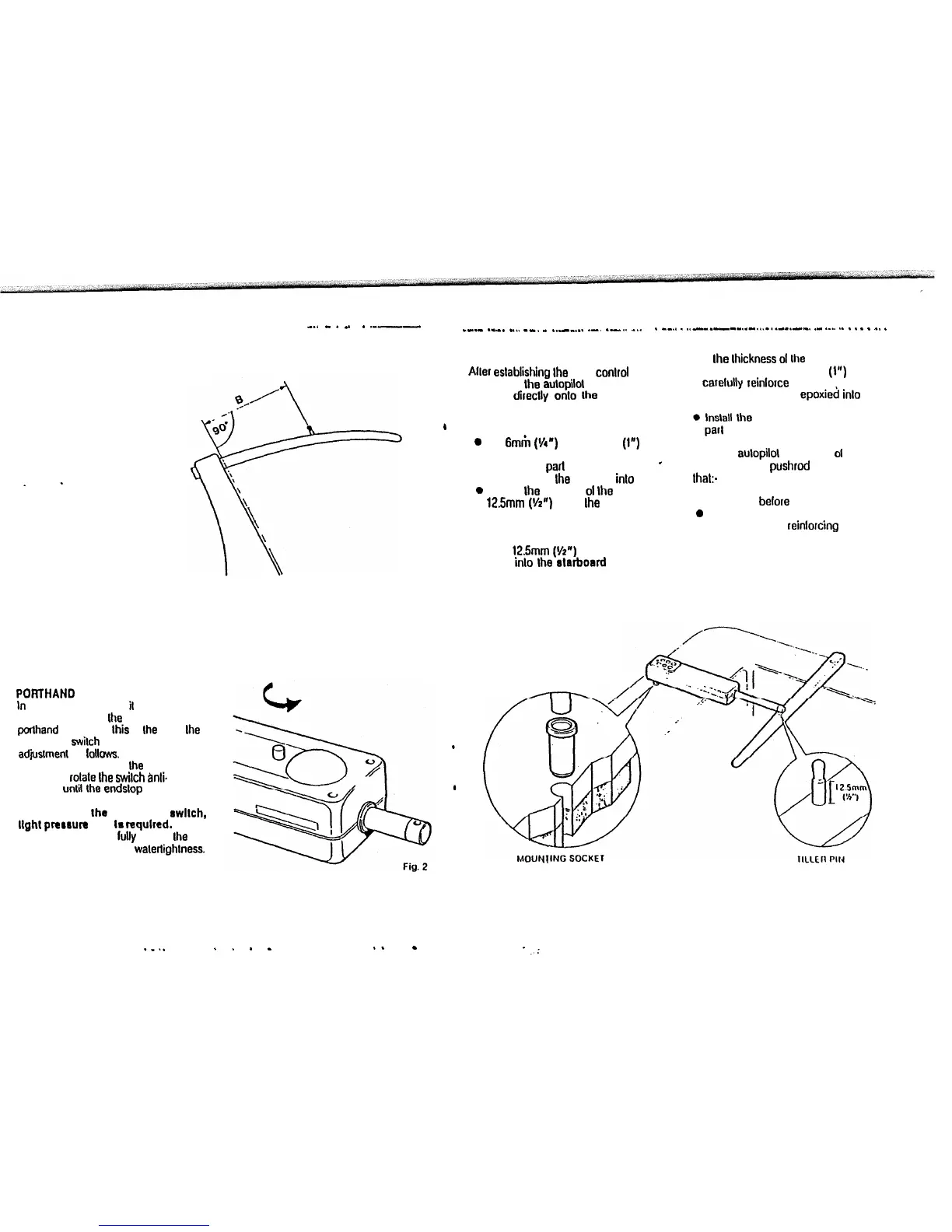

PORTHAND MOUNTING

In

certain circumstances

il

may be more

convenient to mount

Ihe

unit on the

porthand

side. When

lhis

is Ihe case, Ihe

changeover

switch

will require

adjslmenl as

lollows.

Remove the

blanking screw and use Ihe adjusler

provided lo rolale Ihe

swilch

anli-

clockwise

unlil

the

endslop is reached

(Fig. 2.)

Never force the changeover

rwllch,

light

pnraure only

Is

required.

Finally replace and

lully

lighlen Ihe

blanking screw lo ensure walertighlness.

BASIC INSTALLATION

Aller eslablishing Ihe lhree conlrol

dimensions Ihe aulopilot can be

mounled direclly onlo the Slarboard

cockpil seal (Fig. 3). Proceed as lollows.

I

TILLER PIN (Cal No. 0001)

0

Drill

6mm

(Y4”) hole x 25mm

(1”)

deep

al poinl marked.

I

l

Using a Iwo part epoxy such as

*

Araldile, epoxy Ihe liller pin

inlo

place;

0

Posilion Ihe shoulder

01

Ihe pin

12.5mm (Vz”) above Ihe liller surlace.

MOUNTING SOCKET

(Cal No. 0002)

l

Drill

125mm

((/2”)

hole x 25mm (t”)

deep inlo Ihe etarboard cockpil seal.

l

II Ihe lhickness

01

Ihe mounling

posilion is less lhan 25mm (1”)

carelutly reinlorce the under surlace

with a plywood plate epoxied

inlo

posilion;

0

lnslall

the mounling socket using two

par1

epoxy;

Note The aulopilol is capable

01

generaling high pushrod loads. Ensure

Ihat:-

l

The epoxy is allowed lo harden

Ihoroughly belore applying any loads;

0

All holes are drilled lo correct size and

where necessary reinlorcing is

provided.

Fig. 3

2

. .

._..

.

.

.

-

._

a

3

Loading...

Loading...