the power source available and compare it with the

PRELIMINARY INSPECTION

Visually inspect all parts of the operator for shipping

that the correct operator was shipped to you. Also check

items:

damage.

Before proceeding with the installation of your Raynor Jackshaft Operator, it is advisable that you check the following

Check the nameplate located on the powerhead to verify

Check shipping container for damage. Notify delivering

VISUAL INSPECTION

carrier immediately.

5973130-4

electrical data on the nameplate.

PACKAGING

SPRING SHAFT

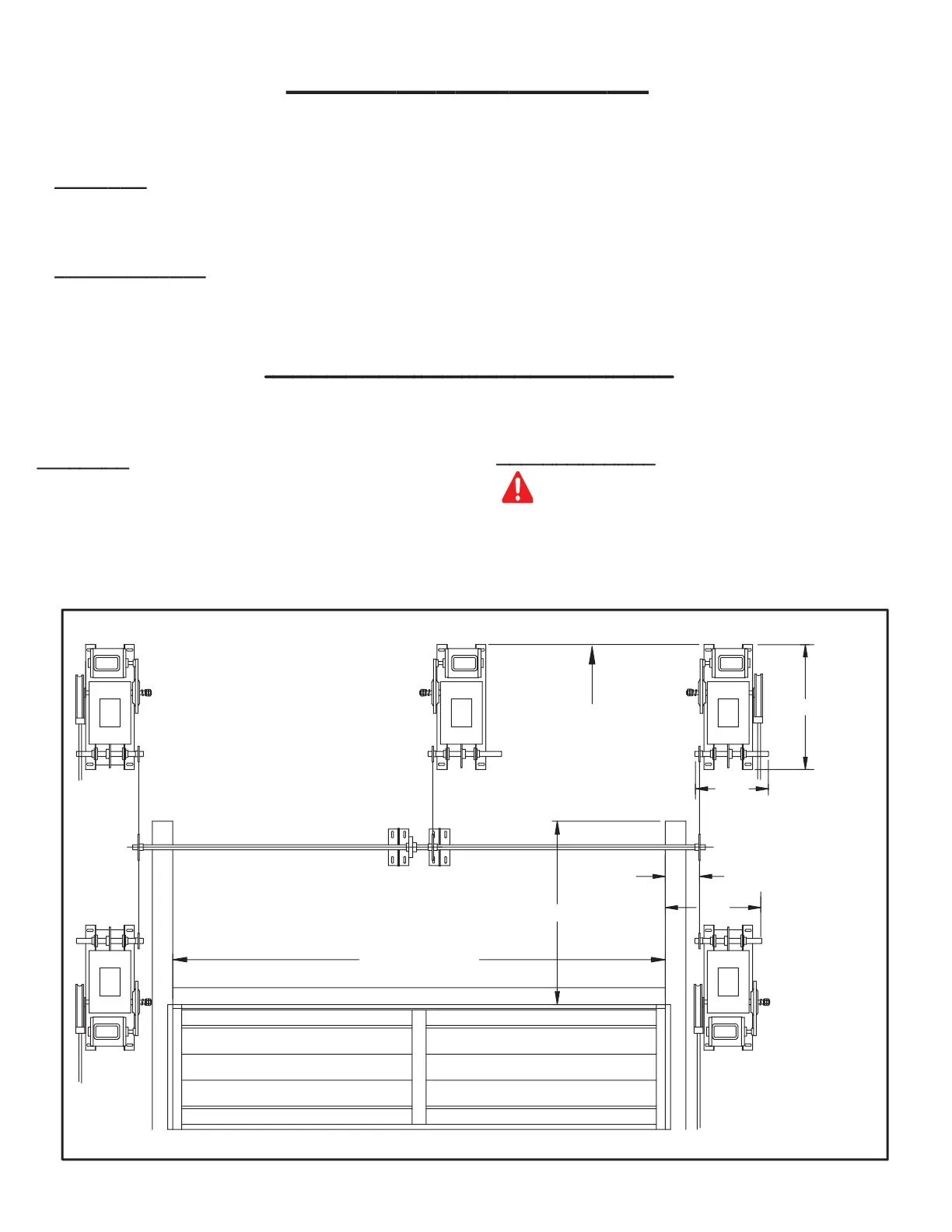

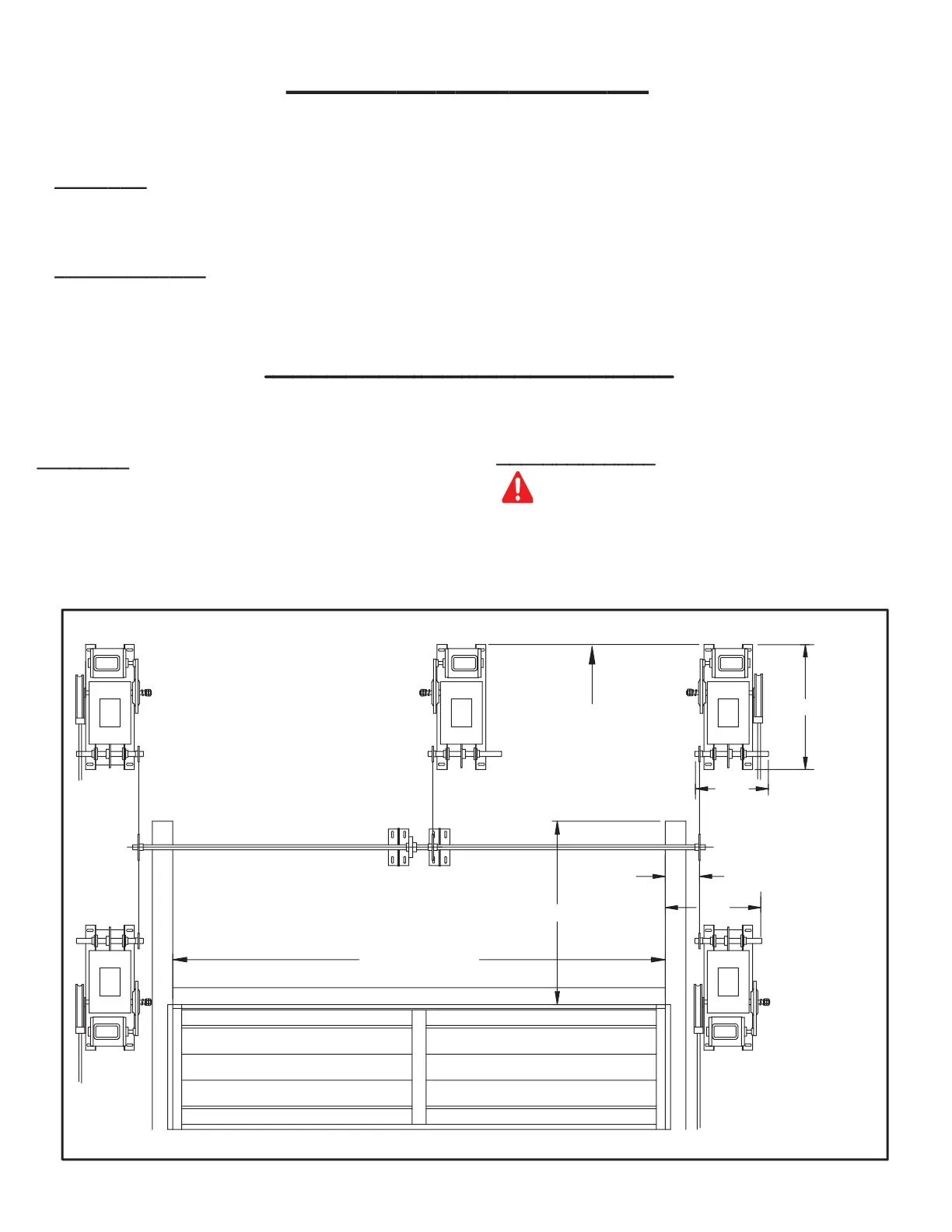

FIG. 1

INSTALLATION INSTRUCTIONS

Many of the problems related to electric operators are due to improper installation. The following installation procedures

are recommended to minimize these problems.

UNPACKING

This unit is shipped in one carton containing the operator

itself, one drive and one driven sprocket, one length of

chain, one control station, and one package of small

hardware. Unpack carton being certain that all loose

parts are removed before discarding packing material.

MOUNTING POSITION

WARNING: This operator has been ordered for a

specific mounting position. Because of differences in

motor rotation, do not install operator in any position

other than that for which it was ordered without first

contacting the factory. See Fig. 1 below.

MOUNTING POSITIONS

May be wall mounted in one of the

following five positions:

Above the shaft - left or right hand drive

Below the shaft - left or right hand drive

Above the shaft center mount -

recommended for doors over 18' wide

Jackshaft operators with hand chains

can not be used in the center position.

HEADROOM

39" maximum headroom is

allowed; measured from the

center point of the

spring shaft.

Opening Width

13"

24"

6-1/2"

20"

SIDEROOM

20" of sideroom required;

measured from the inside edge

of the opening

Position #4

Position #3

Position #2

Position #1

Position #5

Door Headroom

Operator extends out

from wall 11".

Loading...

Loading...