9

7. Bond permanently-wired pumps. The National

Electrical Code requires that the motor be electrically

bonded to the appropriate permanently-installed

pool or spa/hot tub structure using a solid copper

conductor no smaller than No. 8 AWG. The bonding

wire should be connected from the accessible wire

connector on the motor shell to all metal parts of the

swimming pool, spa or hot tub structure and to all

electrical equipment, metal conduit and metal piping

within 5 feet of the inside walls of a swimming pool,

spa or hot tub. A grounding lug is provided on the

exterior of the motor shell for this purpose.

Filter Assembly

Common tools such as screwdrivers, wrenches, and

consumables like pipe sealant for plastic adapters are

required for the installation and service of the sand lter.

See the schematic for layout information, Figure 4.

Pouring Sand Filter Sand Media

1. The filter should be placed on a level concrete slab,

very firm ground, or equivalent. Locate the filter

so that the piping connections, control valve are

convenient and accessible for operation and service.

2. Filter sand media is loaded through the top opening

of the filter as follows:

a. Loosen the flange clamp and remove the filter

control valve (if previously installed).

b. Cap the internal pipe with a plastic cap to prevent

sand from entering it.

c. We recommend filling the tank approximately 1/2

full with water to provide a cushioning effect when

the filter sand is poured in. This helps protect the

under-drain laterals from excessive shock.

d. Carefully pour in the correct amount and grade

of filter sand. (Be sure the center pipe remains

centered in opening.) When done, the sand

surface should be leveled and should come to

about the middle of the filter tank. Remove the

plastic cap from the internal pipe.

Filter Control Valve Assembly

1. Assemble the filter control valve in the filter tank.

a. Insert the filter control valve (with O-ring in place)

into the tank neck, taking care that the center

pipe slips into the hole at the bottom of the valve.

b. Place two plastic clamps around the valve flange

and tank flange and tighten just enough so that

the valve may be rotated on the tank for final

positioning.

c. Carefully screw the pressure gauge (with O-ring

in place) into the tapped hole in the valve body.

Do not over-tighten.

C

B

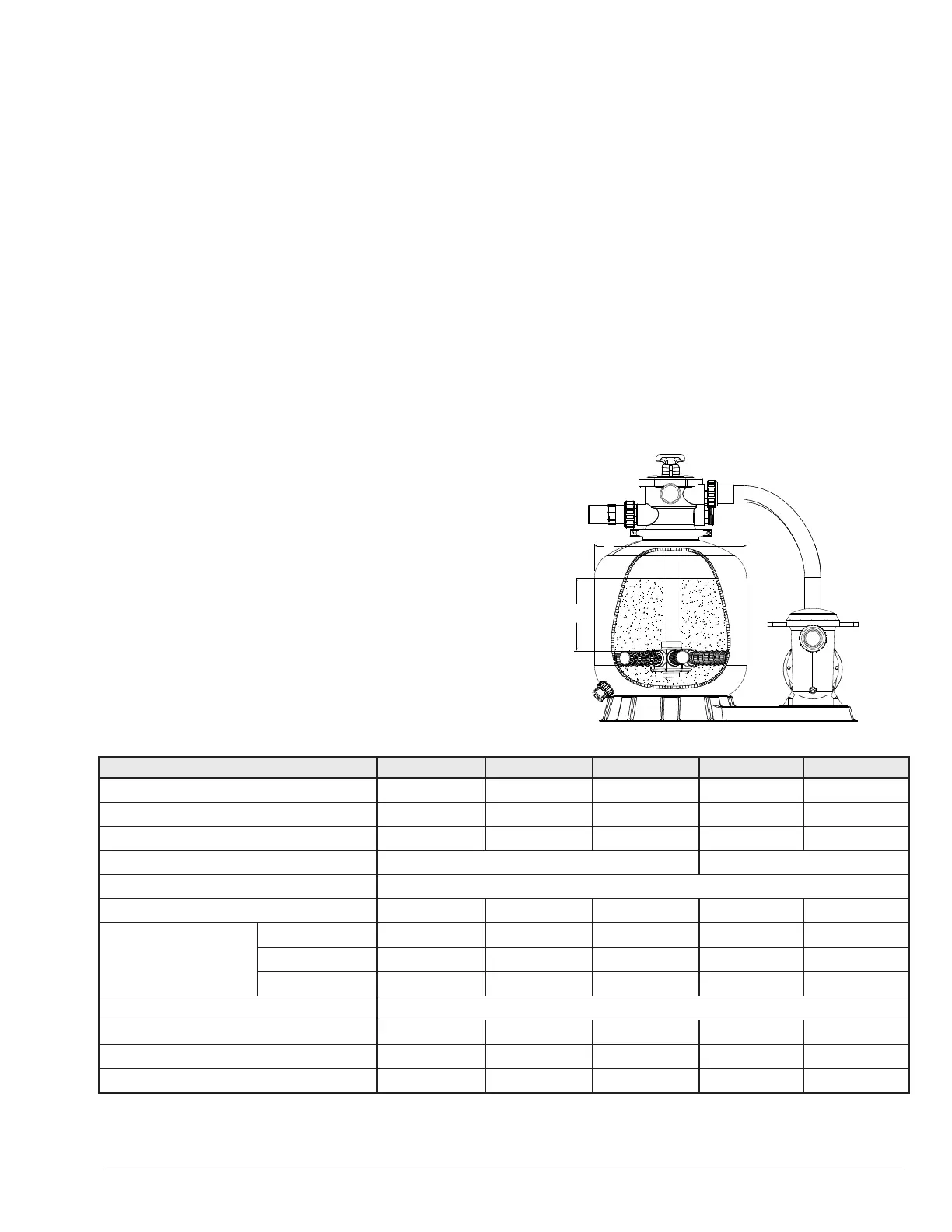

Figure 2. Dimensions

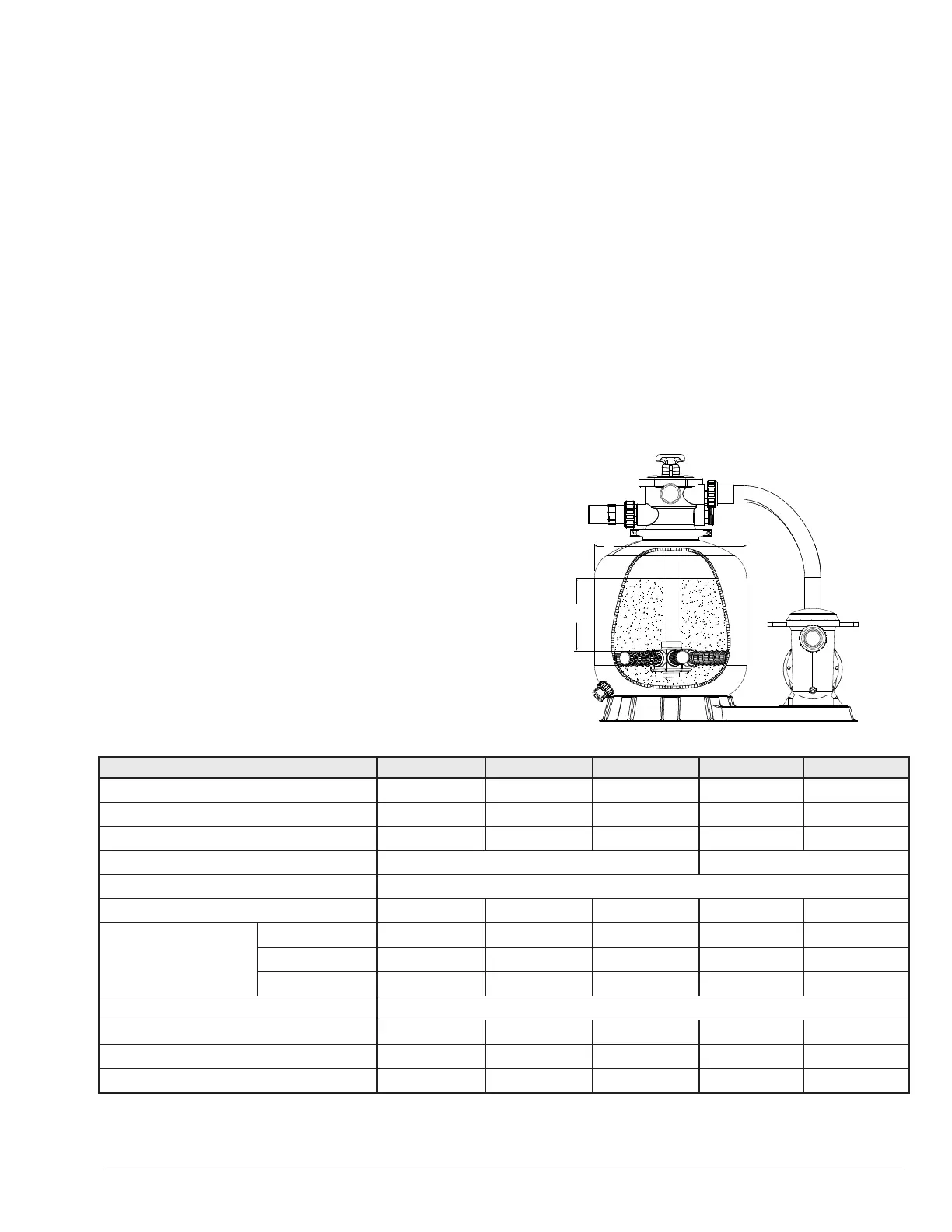

Combo Model RPSFP16 RPSFP18 RPSFP21 RPSFP181 RPSFP211

Filter Model RPSF16 RPSF18 RFSF21 RPSF18 RFSF21

Pump Model RPAGP75 RPAGP100 RPAGP150 RPAGP102 RPAGP152

Power (HP) 0.75 1 1.5 1 1.5

Speed Single Dual

Max Operating Pressure, PSI (bar) 28 (2)

Max Flow Rate Pump + Filter, GPM (LPM) 50 (187) 63 (237) 68 (258) 63 (237) 68 (258)

Turnover Rate, Gal. (L)

2 Hours 6000 (22680) 7560 (28577) 8160 (30845) 7560 (28577) 8160 (30845)

4 Hours 12000 (45360) 15120 (57154) 16320 (61690) 15120 (57154) 16320 (61690)

6 Hours 18000 (68040) 22680 (85731) 24480 (92535) 22680 (85731) 24480 (92535)

Valve Port 1.5"

Filter Dia., in (mm), "B" 15.7 (399) 17.7 (450) 20.7 (526) 17.7 (450) 20.7 (526)

Silica Height, in (mm), "C" 6.9 (175) 8.3 (211) 9.3 (235) 8.3 (211) 9.3 (235)

Silica 16/30* Weight, lb (kg) 77 (35) 99 (45) 209 (95) 99 (45) 209 (95)

*Suggested silica weight is for reference only and based on recommended filter media. Weight will vary based on type and size of media used.

Recommended Filter Media: 16/30 Mesh Silica Sand / Silica #20 (0.5 - 0.8mm diameter)

Table A. Specications

Loading...

Loading...