CONTROL METHODS HeatNet Control V3

Page 18

Fault tolerance allows for one boiler in the Priority 1 system

to fail and any boiler(s) in the Priority 2 system to fail and

still provide near linear (continuity) BTU response when

adding boilers. This is illustrated in the following examples

using the Boiler System Response graphs.

The CK Series/Futera III/Fusion-Series Mixed Boiler

System (examples) is advantageous in providing low BTU

input for light loads and high BTUs for heavy loads. The

effective system turndown minimizes short cycling when

light loads are present by assigning smaller boilers to

Priority 1, running them first, and then stopping them last.

In order to achieve the high effective

turndown, smaller boilers are required

(plumbing considerations need to be

considered here due to differing flow/volume

characteristics through the large and small

boilers).

Example Systems:

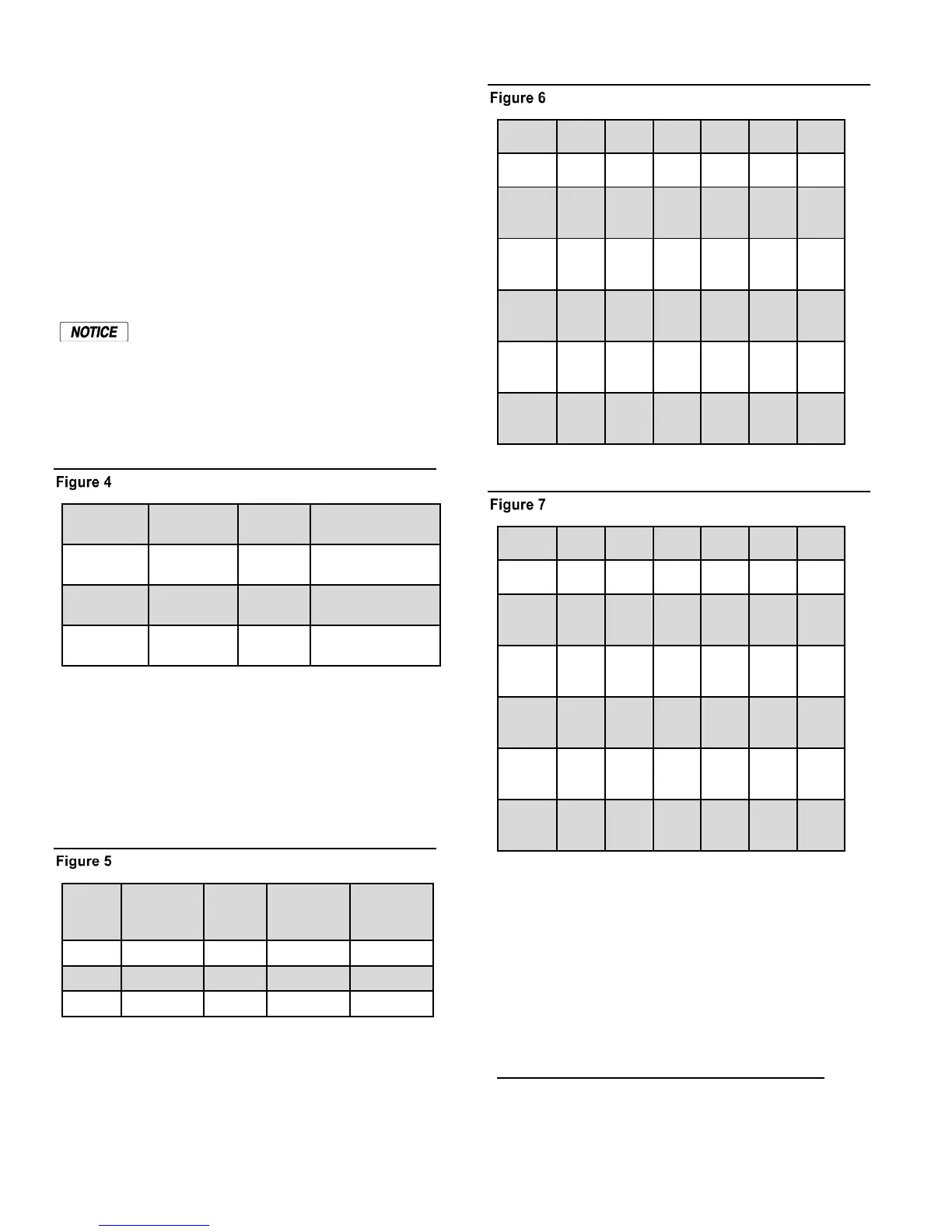

Non-Mixed Boiler System Examples

With the traditional Non-Mixed boiler system, the effective

turndown increases by the turndown ratio for every boiler

added. The min fire rate is equal to the minimum BTUs that

can be delivered to the system.

Number of boilers * Turndown Ratio = Effective System

Turndown: 5 * 5:1 = 25:1.

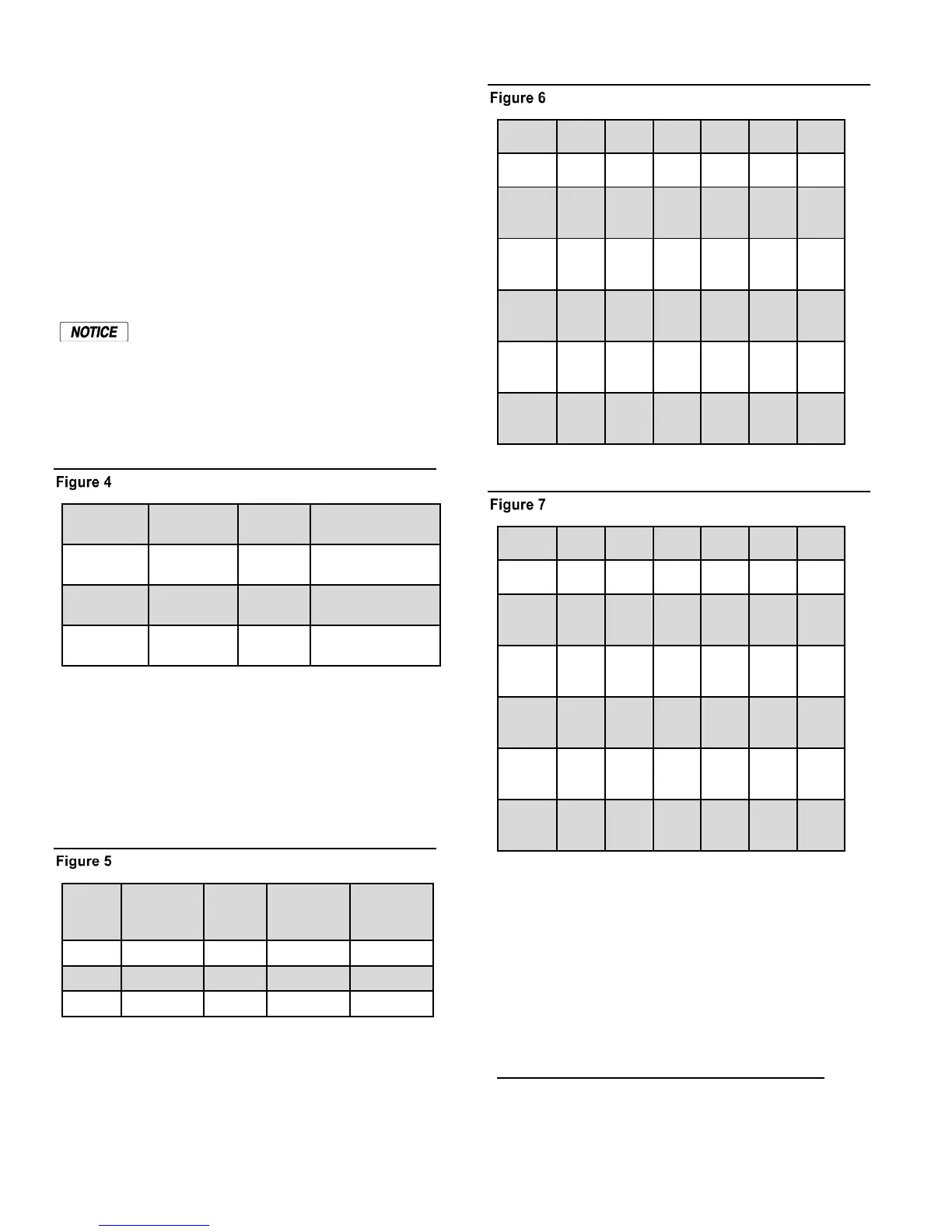

Mixed Boiler System Examples

With the mixed boiler system, a lower minimum fire

rate/BTU can be delivered to the system by using small

boilers with larger boilers. This works in much the same

way as base loading.

CK Series 1500 – 4000 Modulation Parameters

CK Series 4500- 9000 Modulation Parameters

When selecting the Priority 1 boiler(s) for a high effective

system turndown, the BTU Min Input is selected first. (See:

CK/Futera III/Fusion Boiler Btu Chart). Next, the MOD-

MAX value of this Priority 1 boiler needs to be greater than:

Mod MAX % =

(Priority 1‘s Min Input + Priority 2‘s Min Input)

Max Input of the Priority 1 boiler

Loading...

Loading...