CONTROL METHODS HeatNet Control V3

Page 19

The reason for this is to keep the continuity of BTUs linear

without a BTU bump (discontinuity) when boilers are added

or shed. The Mod Max % can be adjusted to the high side to

allow for tolerance (about 10%) as is indicated in the tables.

This is illustrated in the Boiler System Response 2 graph.

If redundancy is not required, the min inputs of the

Priority 1 boilers may be summed to lower the Mod Max %

value so smaller Priority 1 boilers can be used. The sum of

the min inputs would then need to be divided by the sum of

the Max Input of the Priority 1 boilers. The effect of this

would create a higher turndown. See: EXCEPTION NOTES:

Mod MAX % =

(((Priority 1 Min) * (#Priority 1’s)) + Priority 2 Min)

Max Input of Priority 1 boiler * (#Priority 1’s)

Example: (2) CK 1500, (2) CK 2500

Redundancy: (300 + 500)/1500 = 53%

No Redundancy: (300 * 2) + 500) / (1500*2) =36%

In this example, if “Redundancy” is used, the variable “# of

Priority 1’s” is not used.

EXCEPTION NOTES:

1. Mixing more than two different size/type boilers

becomes more complex than the scope of this manual

and is not recommended.

2. If using more than one Priority 1 boiler and the

calculated value is <

Priority 1Min * 2

Priority 1 Max Input

Use this result PLUS note 3 value as the

ModMax %.

3. Always add a few % (3-5%) to the calculated MOD

MAX % value to allow a guard band (tolerance).

4. If boilers are of different sizes, try to use larger Priority

2 boilers.

If the calculated Mod MAX % value is greater

than 99%, the combination cannot be used

since short cycling will occur.

Once the Priority 1 and Priority 2 boilers are selected, they

can be multiplied in each Priority set to achieve the desired

system design BTUs. If the # of boilers becomes a large

number, a Priority 1 boiler with a higher Min Input may

need to be selected.

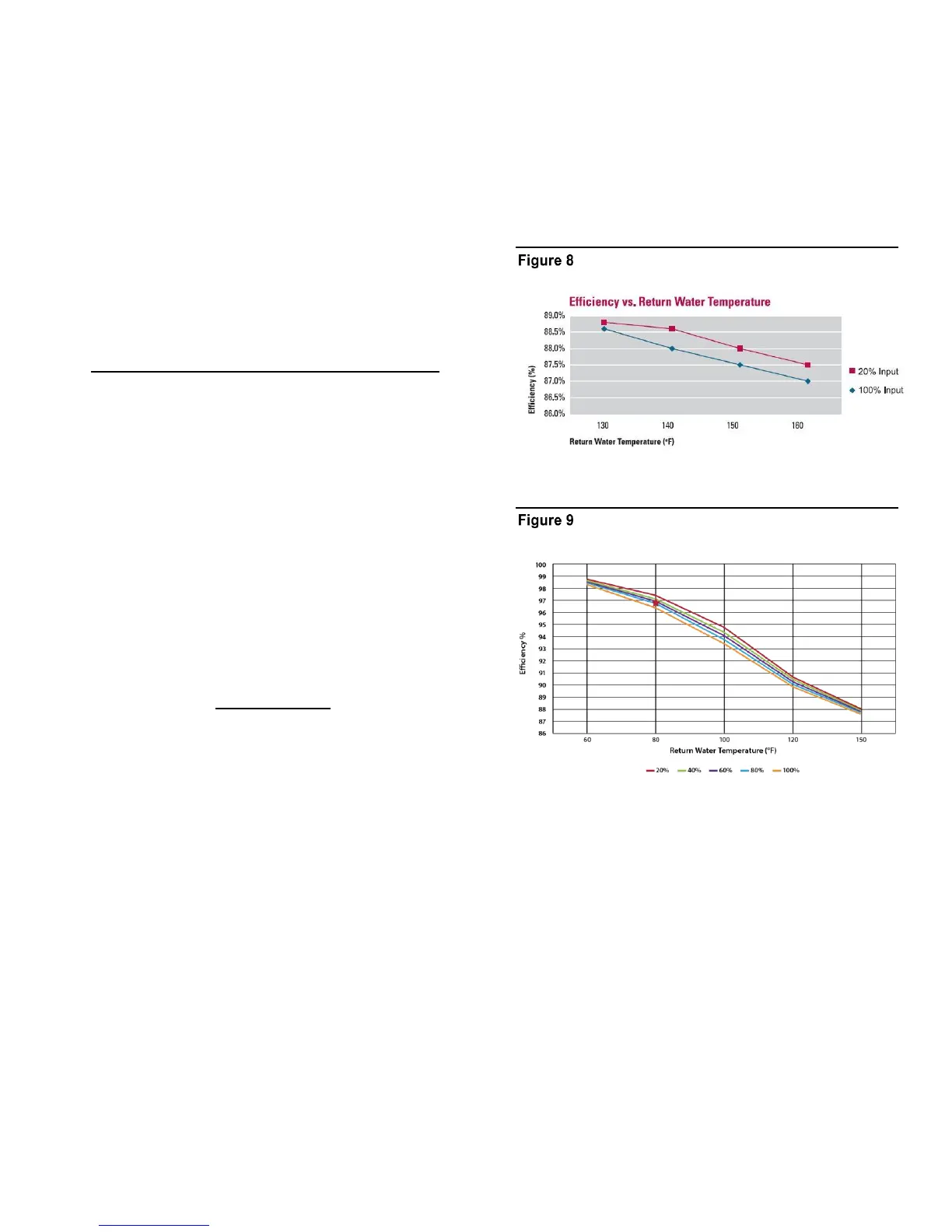

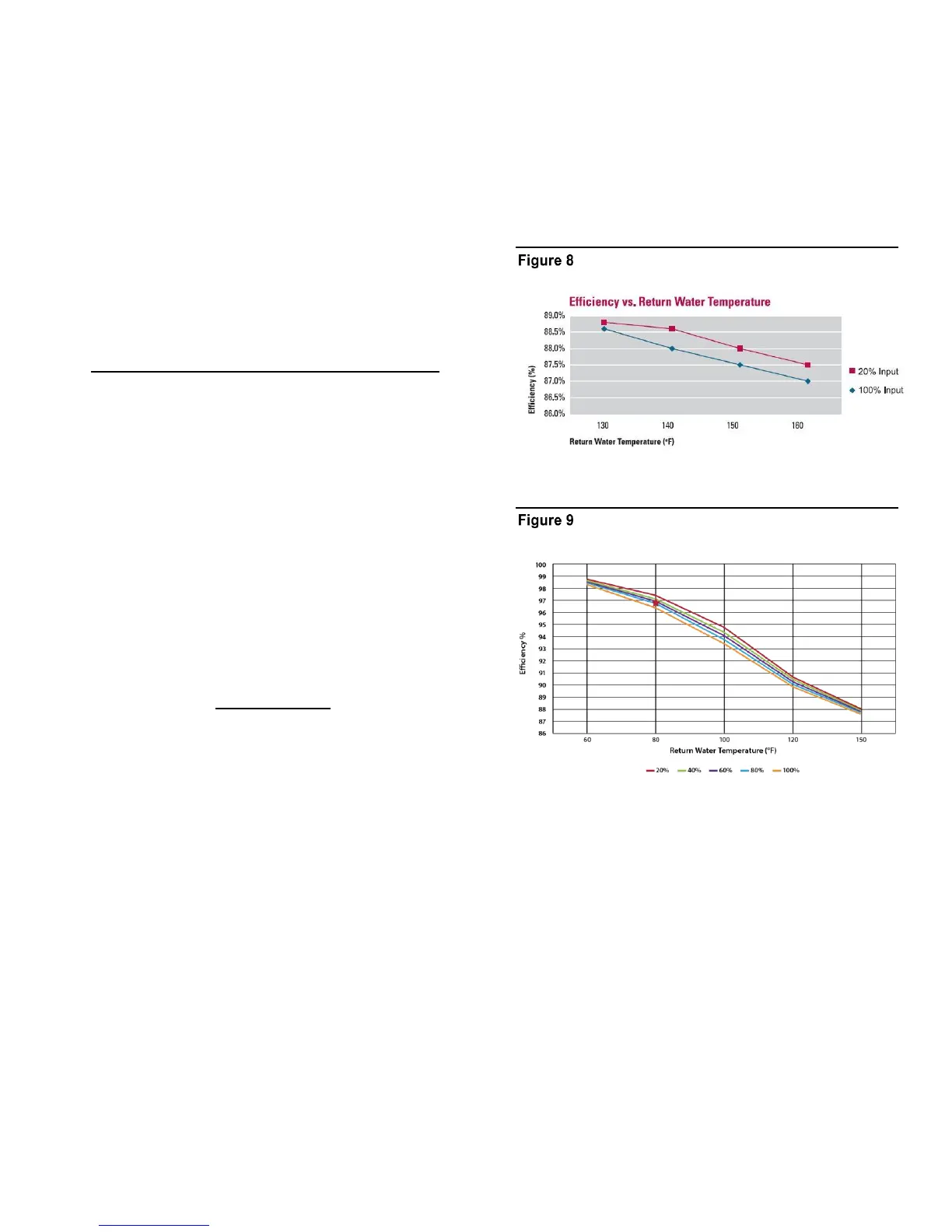

While considering the MOD-MAX value, the lower the

MOD-MAX the greater the combustion efficiency since it

effectively limits the input rate. The Typical Efficiency of

Non-Condensing Boilers chart can help illustrate how the

MOD-MAX value can affect the efficiency by limiting the

input until all boilers have fired. Non-condensing boiler

efficiency is relatively flat compared with condensing as

illustrated in the Typical Efficiency of Condensing Boiler

graph.

Typical Efficiency of Non-Condensing Boilers

Typical efficiency of Flexcore boilers

In the Mixed Boiler System table line 1 example, (2) CK

1500s are set as Priority 1 and (2) CK 2500 boilers are set

as Priority 2. With a MOD MAX of 50% (Redundancy),

each 1500 can run to 750M (1500M total) before a 2500 is

called ON (Add Delay timer). Once both 1500s are running

and the 2500 is called on, all (3) boilers will drop to a sum

of 1500M BTUs: Taking this1500M value and dividing by

total M BTUS of the (3) boilers, 1500 +1500+1750 = 5500,

we get 27.27%. (.2727* 1500M) + (.2727* 1500M) +

(.2727* 2500M) or: 409M +409M + 681M = ~1500M and

operate at higher combustion efficiencies

Loading...

Loading...