4

Cast Iron Condensing Boilers – Installation Manual

FlexCore Stainless Steel Condensing Boilers – Installation Manual

Buildings will require the installation of a fresh air duct

or other means of providing make-up air if the intake

air option isn't used. Any building utilizing other gas

burning appliances, a fireplace, wood stove or any type

of exhaust fan must be checked for adequate

combustion air when all of these devices are in

operation at one time. Sizing of an outside air duct must

be done to meet the requirements of all such devices.

Never operate the FlexCore in an environment

subjected to a negative pressure. Failure to

comply with this warning can result in

excessive levels of carbon monoxide causing

severe personal injury or death!

All Air From Inside The Building

If the boiler is to be located in a confined space the

minimum clearances listed in Table 1 must be

maintained between it and any combustible construction.

When installed in a confined space without the intake

air option two permanent openings communicating with an

additional room(s) are required. The combined volume of

these spaces must have sufficient volume to meet the

criteria for an unconfined space. The total air requirements

of all gas utilization equipment, fireplaces, wood stoves or

any type of exhaust fan must be considered when making

this determination. Each opening must have a minimum

free area of 1 in

2

/1000 Btu/hr, 2200 mm

2

/kW based on the

total input rating of ALL gas utilization equipment in the

confined area. Each opening must be no less than 100 in

2

,

64,516 mm

2

in size. The upper opening must be within 12

in, 300 mm of, but not less than 3 in, 80 mm from, the top

of the enclosure. The bottom opening must be within 12 in,

300 mm of, but not less than 3 in, 80 mm from, the bottom

of the enclosure.

All Air From Outside The Building

When installed in a confined space without the intake

air option two permanent openings communicating

directly with, or by ducts to, the outdoors or spaces that

freely communicate with the outdoors must be present.

The upper opening must be within 12 in, 300 mm of,

but not less than 3 in, 80 mm from, the top of the enclosure.

The bottom opening must be within 12 in, 300 mm of, but

not less than 3 in, 80 mm from, the bottom of the enclosure.

Where directly communicating with the outdoors or

communicating with the outdoors through vertical ducts,

each opening shall have a minimum free area of 1in

2

/

4000 Btu/hr, 550 mm

2

/kW of the total input rating of all

of the equipment in the enclosure.

Where communicating with the outdoors through hori-

zontal ducts, each opening shall have a minimum free

area of 1 in

2

/2000 Btu/hr, 1100 mm

2

/kW of the total

input rating of all of the equipment in the enclosure.

When ducts are used, they must have the same cross-

sectional area as the free area of the opening to which

they connect.

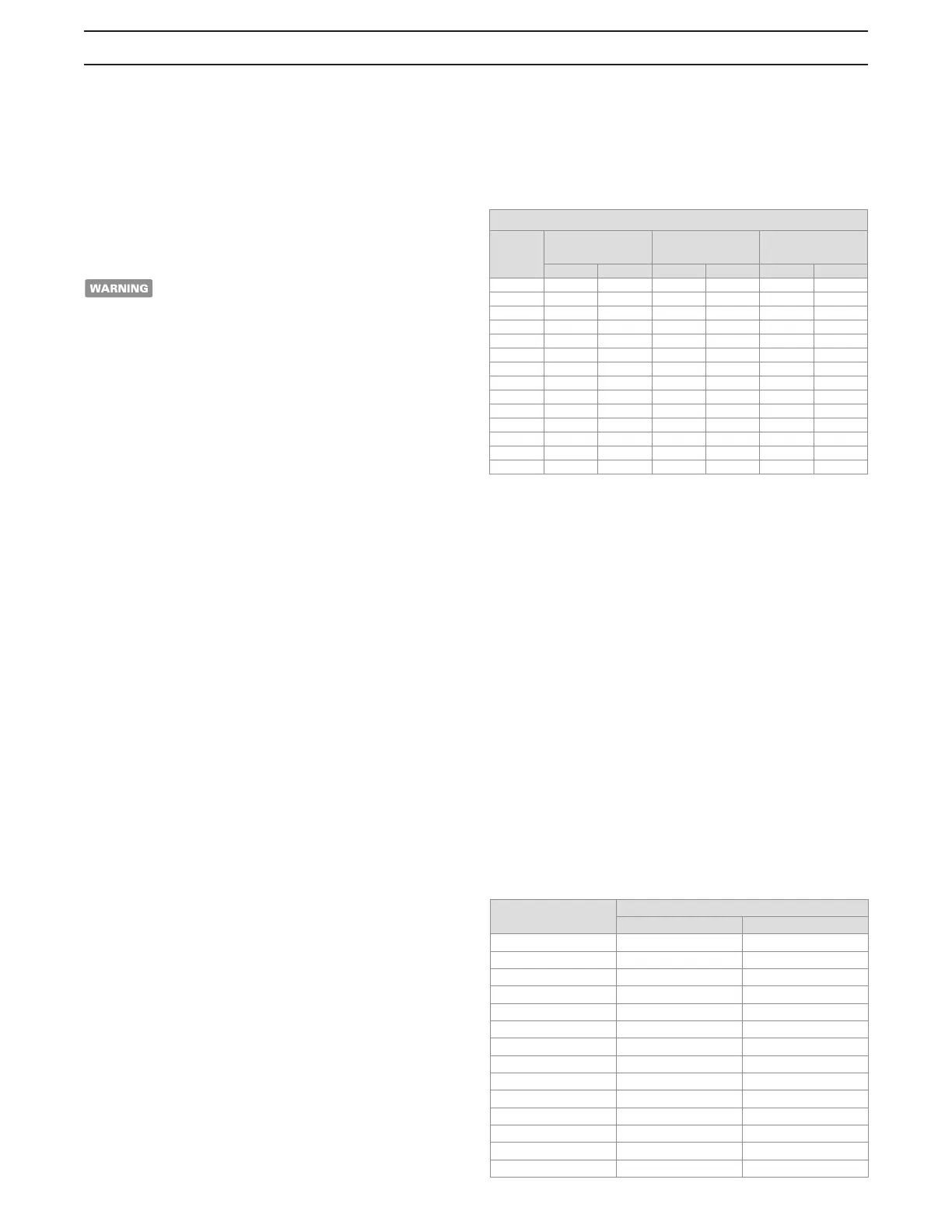

Table 2 - Make-up Air Duct Sizing

When calculating the free area necessary to meet the

make-up air requirements of the enclosure,

consideration must be given to the blockage effects of

louvers, grills and screens.

Screens must have a minimum mesh size of 1/4 in,

6.4 mm. If the free area through a louver or grill is not

known ducts should be sized per Table 2.

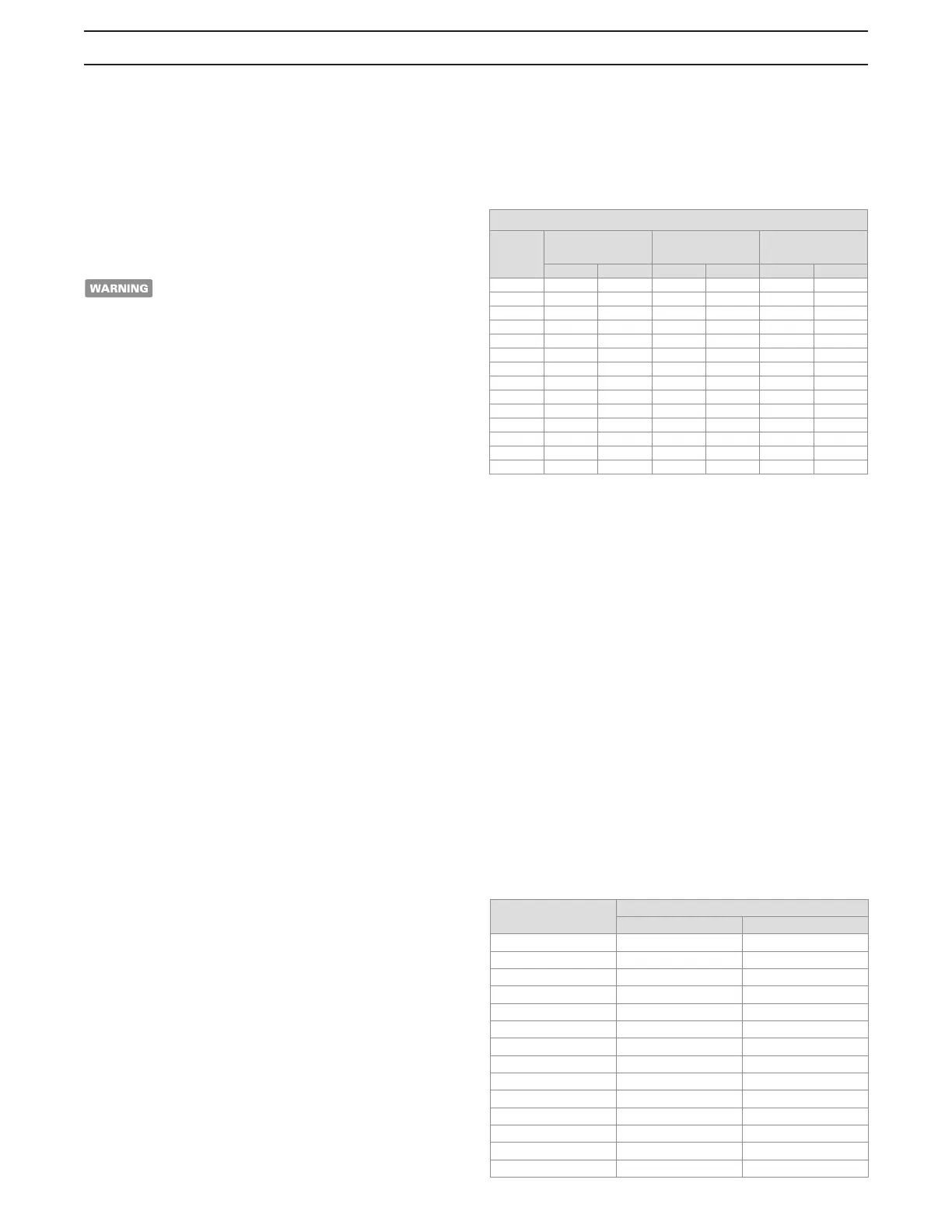

Direct Intake Air Option - General

This configuration provides combustion air directly to the

boiler’s air intake using a dedicated pipe when using the

direct vent option. Combustion air can be drawn in

horizontally through an outside wall or vertically through

the roof, see Figures 2, 3, 4 & 5. It must be sized per

Table 3.

Single wall galvanized smoke pipe, single wall aluminum

pipe, flexible aluminum pipe, PVC or CPVC pipe can be

used for the intake air pipe.

Table 3 - Intake Air Pipe Sizing

Required Cross Sectional Duct Area

Input

(MBH)

1/4 in, 6.4 mm

Wire Screen

Metal

Louvers

Wooden

Louvers

in

2

cm

2

in

2

cm

2

in

2

cm

2

0850 212 1368 283 1826 850 5484

1000 250 1613 333 2148 1000 6452

1500 375 2419 500 3226 1500 9677

2000 500 3226 667 4303 2000 12903

2500 635 4031 833 5382 2500 16127

3000 750 4838 1000 6452 3000 19354

3500 875 5645 1167 7522 3500 22581

4000 1000 6452 1334 8592 4000 25808

4500 1125 7257 1500 9678 4500 29031

5000 1250 8065 1666 10748 5000 32258

6000 1500 9676 2000 12904 6000 38708

7000 1750 11290 2334 15044 7000 45162

8000 2000 12904 2668 17184 8000 51616

9000 2250 14514 3000 19356 9000 58062

Model

Size

Pipe Diameter

in mm

0850 6 153

1000 6 153

1500 8 204

2000 8 204

2500 8 204

3000 8 204

3500 10 254

4000 10 254

4500 10 254

5000 12 305

6000 12 305

7000 14 356

8000 14 356

9000 14 356

Loading...

Loading...