3

ENAMEL

FORMEX

SLEEI//NG

BBON

OREEN

YELLOW

RED

BLACK

S.D 50LCERE:,

To OCEEN'

LEAD -

áREEN

III

SLACK

rp

.ED

BLUE

T

L-+REFN

I- --I./

RED

VZ II'

BLACK

\'L /BLACK

YELLOW

YELLOWx

SLEEY/N,n -

BLACK

7-n977B-1

TYPE 77D

8,77DX

MICRGP'IONE

_ ORED

1

C. BLK. I j kED

1

GRN.

BLK.

;ì

j

SRN.

- 1501

(iLK.

RED

.IRN.

G50

CABLE

CONNECTIONS

M I- 4045

E aMe!

M/-404SF

MI - I 1 706 B

an!

MI-//006C

M -

149778

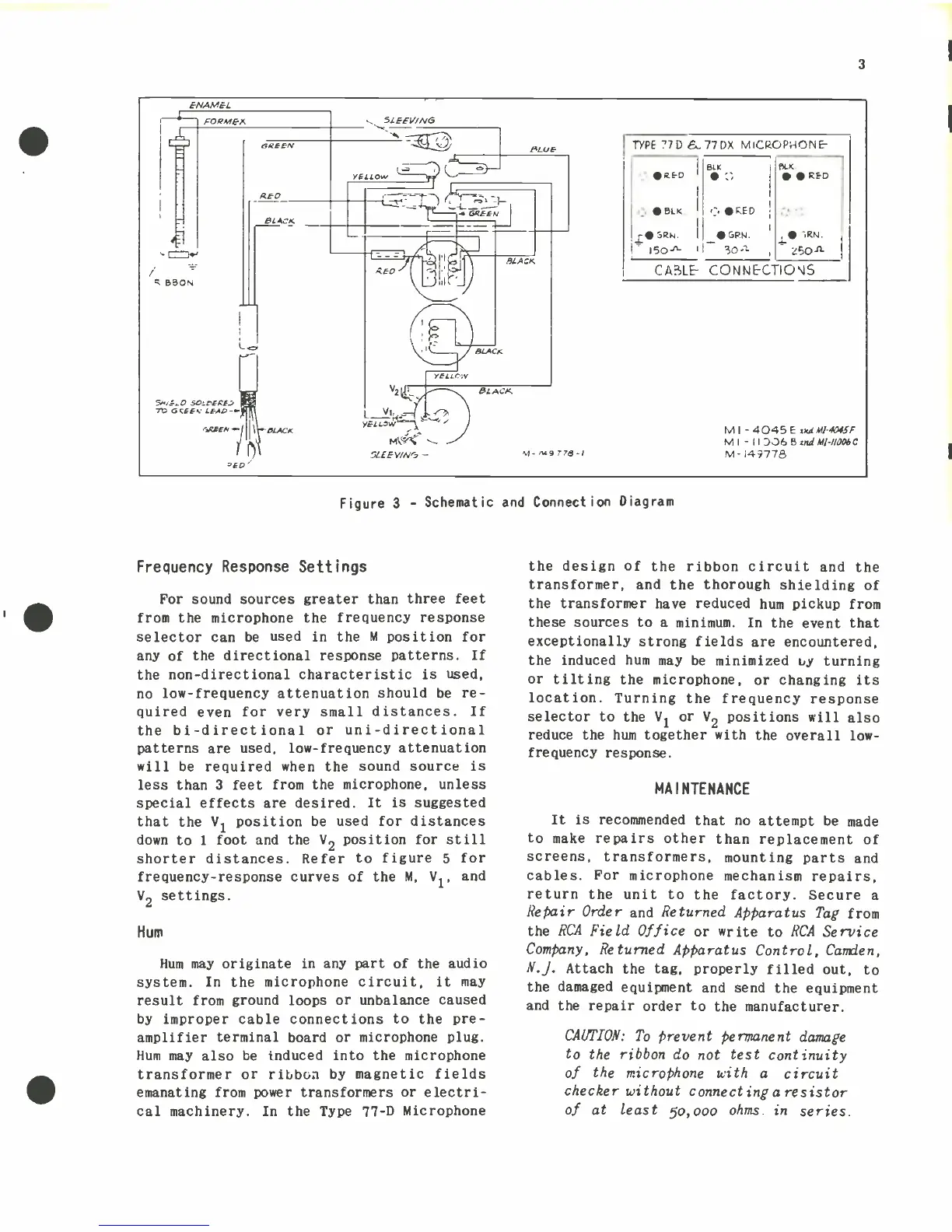

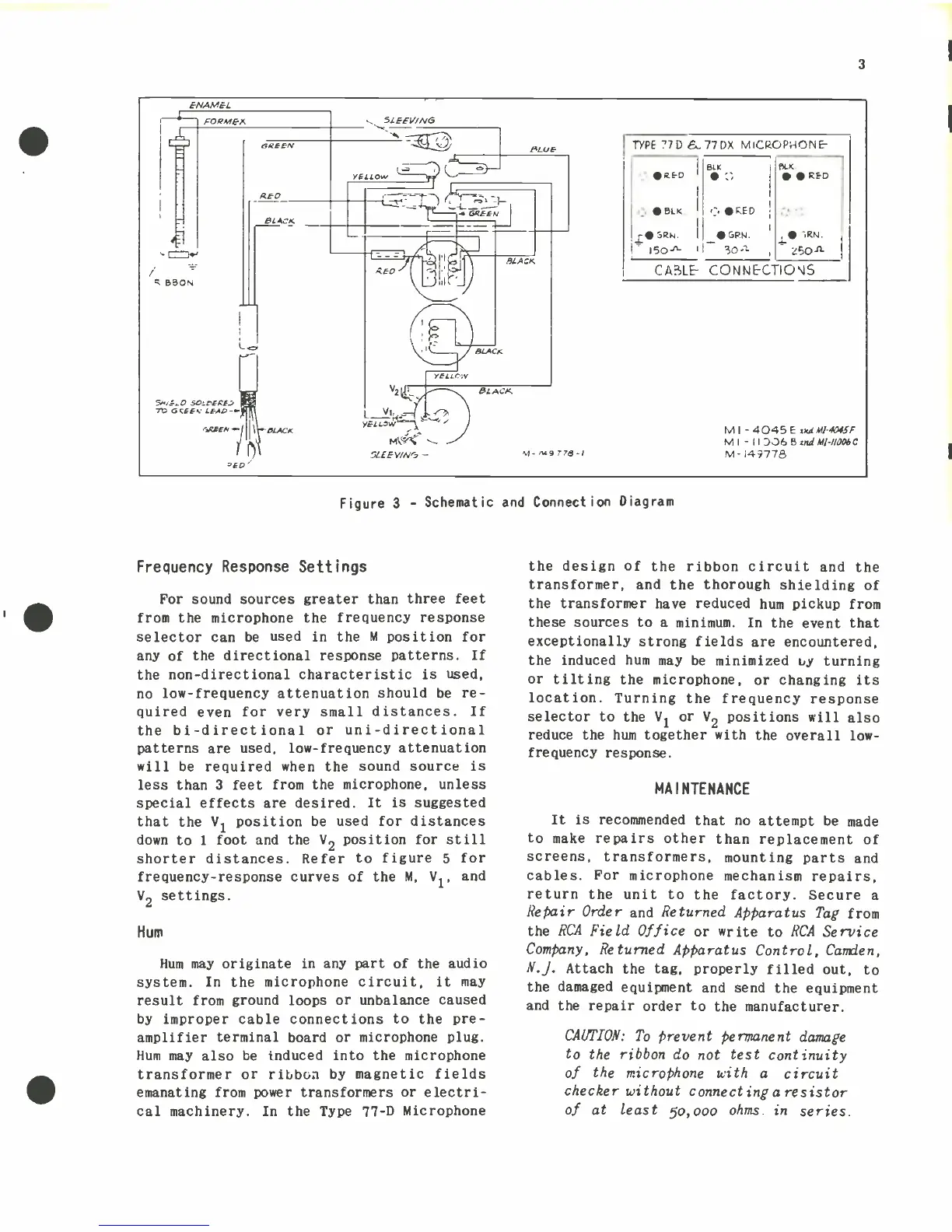

Figure 3 -

Schematic

and

Connection

Diagram

Frequency

Response

Settings

For sound sources greater than

three feet

from the microphone the frequency response

selector

can be

used in the M position

for

any of the

directional

response

patterns. If

the

non

-directional

characteristic is

used,

no

low- frequency

attenuation should be

re-

quired

even

for very

small

distances.

If

the bi-

directional

or uni-

directional

patterns

are

used,

low-

frequency attenuation

will

be required

when

the

sound source is

less than 3

feet from the microphone,

unless

special effects

are

desired. It is suggested

that the VI position

be

used for distances

down to

1

foot

and

the V2 position

for still

shorter distances. Refer to figure

5

for

frequency-

response curves of the

M, V1,

and

V2 settings.

Hum

Hum may originate in any part of

the

audio

system. In the microphone

circuit, it may

result

from

ground loops

or unbalance caused

by improper cable connections

to the

pre-

amplifier terminal board or

microphone plug.

Hum may also

be

induced

into

the microphone

transformer

or

ribbon

by magnetic

fields

emanating

from power transformers or electri-

cal machinery. In the Type

77

-D

Microphone

the

design of the

ribbon circuit

and the

transformer, and

the

thorough

shielding

of

the transformer

have

reduced

hum

pickup from

these sources

to a minimum. In

the

event

that

exceptionally strong fields

are

encountered,

the induced hum

may be minimized 6,y

turning

or tilting the microphone,

or changing

its

location. Turning

the frequency

response

selector to the VI

or

V2 positions

will

also

reduce the hum

together

with

the

overall low

-

frequency

response.

MAINTENANCE

It

is

recommended

that

no attempt

be made

to

make

repairs other than

replacement

of

screens,

transformers,

mounting

parts

and

cables.

For microphone

mechanism

repairs,

return

the unit

to the

factory. Secure

a

Repair

Order

and

Returned

Apparatus

Tag

from

the

RCA Field

Office

or

write

to

RCA

Service

Company,

Returned Apparatus

Control,

Carden,

N.J.

Attach

the

tag, properly filled

out, to

the

damaged

equipment and

send the

equipment

and

the repair

order to the

manufacturer.

CAUTION:

To

prevent

permanent

damage

to

the ribbon

do not test

continuity

of

the

microphone with

a circuit

checker

without connecting

a resistor

of

at

least

5o,000

ohms. in

series.

Loading...

Loading...