Next, rotate the Cylinder Bushing Assembly counterclockwise to reduce weight or rotate

clockwise to increase weight. If Cylinder Bushing is dicult to rotate loosen Brass Lock

Screw another 1/16th of a turn. When adjustment has been made and desired metered

powder charge is being dispensed, rotate Brass Lock Screw clockwise to secure Metering

Screw in place.

Note: be careful when setting metering screw for light

loads. The Metering Screw can be advanced all the way

in until it contacts the machined bore, when this is done

it needs to be advanced outward slightly, approximately

1/8-1/4 turn, to ensure there is adequate clearance

through entire range of the Metering Cylinder rotation.

When you meter powder, initially after setting up for light

load, you may nd that the Metering Cylinder binds up

and is dicult to rotate. If this happens simple loosen

the Brass Lock Screw and advance Metering Screw out

slightly until Metering Cylinder rotates freely. This will be

the lowest setting you will achieve with this powder type.

When setting up for light loads rotate Metering Cylinder

slightly so it is in the position shown (right). This ensures

the Metering Screw is not advanced passed the bore and

into the powder drop area of the casting.

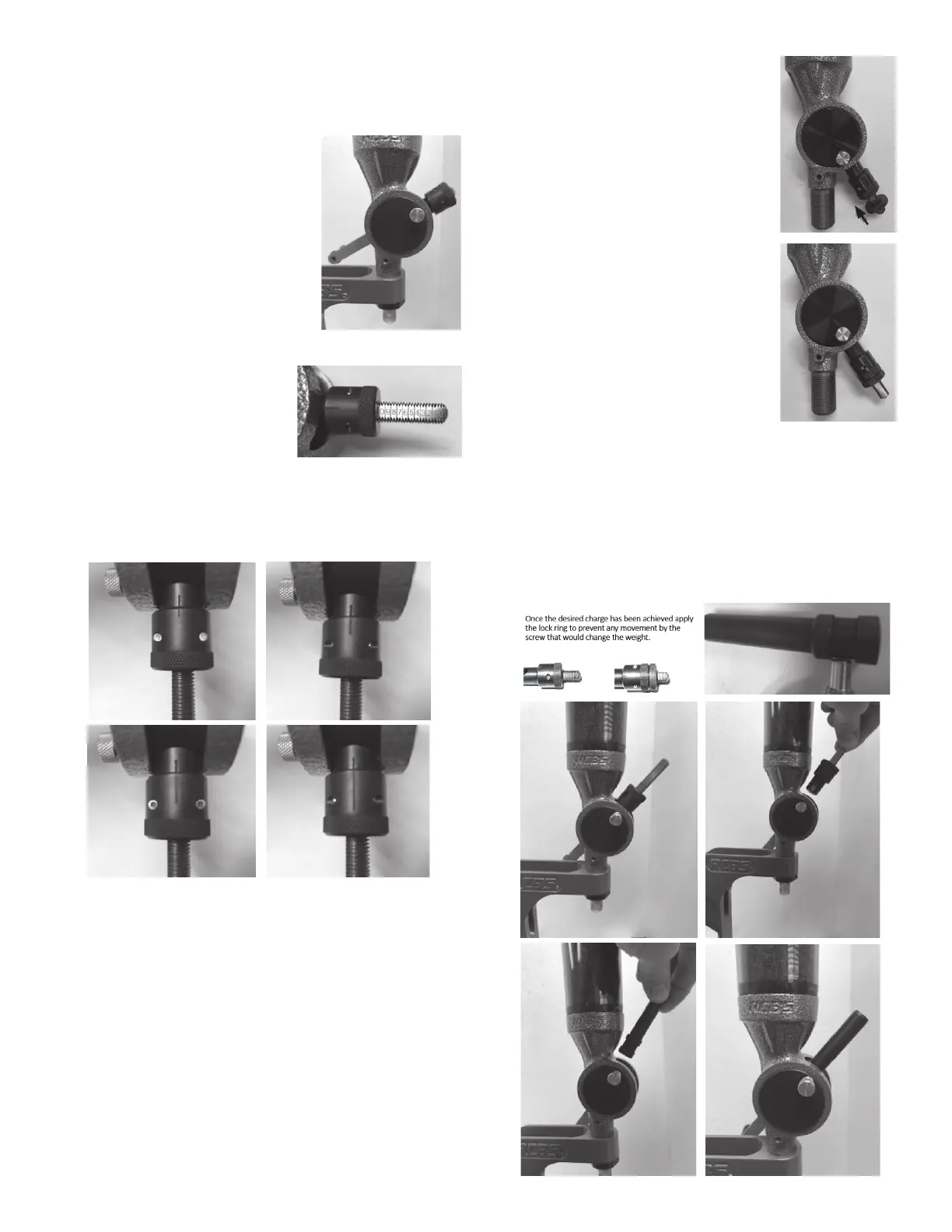

The Metering Screw has a reference scale engraved

on the at portion of the Metering Screw (right). This

allows for recording the setting for a specic powder

type and charge weight being metered. This allows

for quicker setup during the next reloading session.

The Thimble on the Cylinder Bushing Assembly has

four dierent size engraved markings (below), each

marking is 90 degrees apart, to assist in recording

the powder setting. One complete turn of the

Cylinder Bushing will result in .050” of travel of the Metering Screw. Knowing how much the

metered charge will increase or decrease with one complete turn of the Cylinder Bushing will

aid in setting the UPM-3 for desired charge weight. Example: If metering Alliant 300 MP Ball

Powder and the Metering Screw is advanced outward by one rotation of the Cylinder Bushing,

the metered charge will increase by approximately 4.5 grains.

Before using UPM-3 to reload actual cartridges, we need to condition the Powder Measure,

to do this, set the powder measure for the maximum charge by rotating the Cylinder Bushing

Assembly clockwise, this will advance the metering screw outward until it reaches the end of

its travel. Fill the Hopper with powder and cycle UPM-3 until all powder has been metered and

dispensed. The UPM-3 holds approximately 1/2 pound of powder, so do this twice so a total of

one pound of powder has been metered through the Powder Measure. Doing this will deposit

a thin lm of graphite on the internal features allowing the powder to ow more evenly and

smoothly resulting in more consistent metered charges.

Checking the weight of the dispensed volumetric charge is very important and needs to be

done every time the UPM-3 is set up and used. This should also be done if the reloading session

is stopped and started at a later time. This can be done by weighing the dispensed volumetric

charge on either an electronic or mechanical scale.

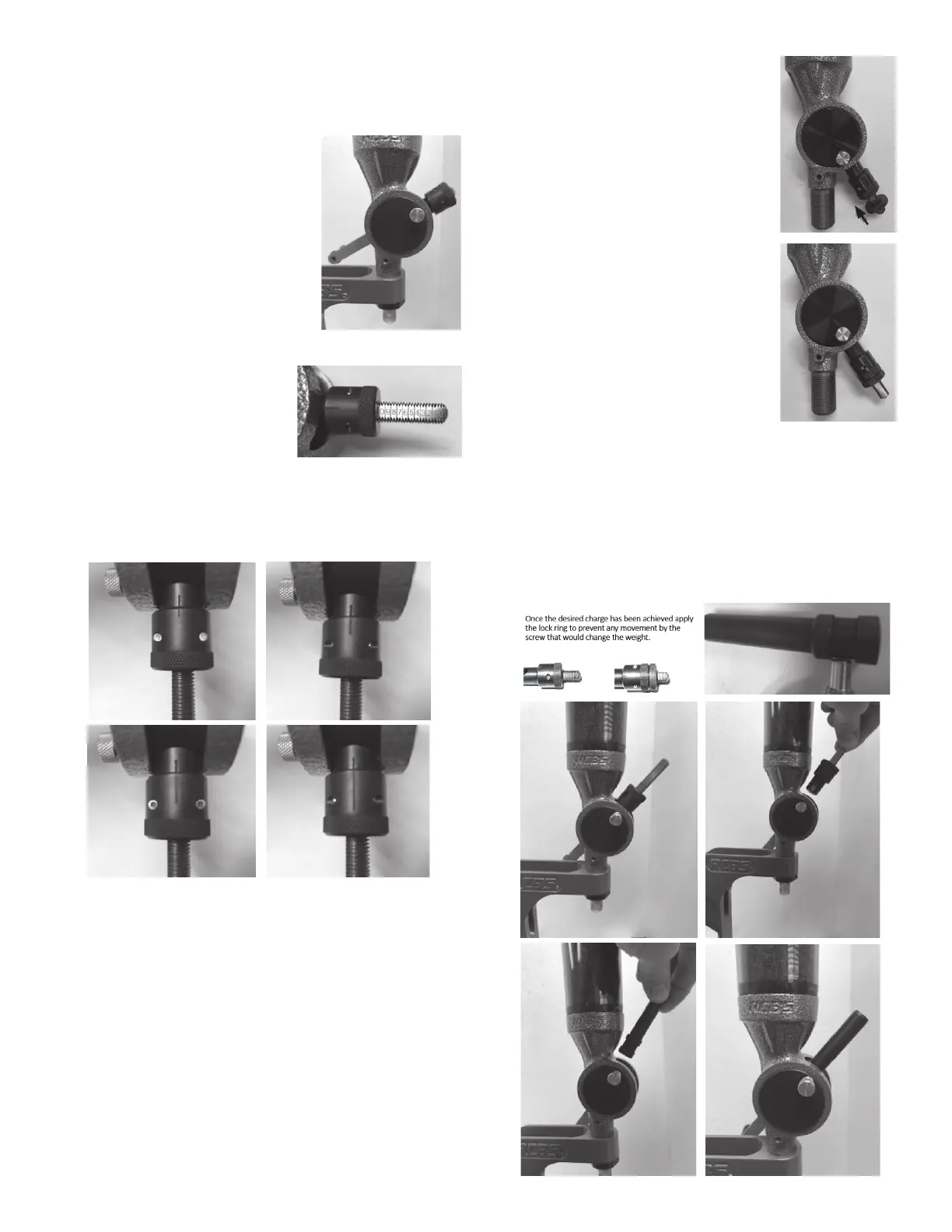

Once the powder measure has been set, place the Screw Lock Ring, from Bag 3, onto the

Metering Screw and rotate clockwise until it makes contact with the Cylinder Bushing Assembly,

acting as a jam nut preventing any unwanted rotation of the Cylinder Bushing Assembly and

preventing any unwanted movement of Metering Screw. If the amount of powder being

dispensed needs to be adjusted, you will need to loosen the Screw Lock Ring prior to adjusting,

as shown in Figure A. Once the desired amount of powder dispensed is achieved re-tighten

the Screw Lock Ring as shown in Figure B. Cycle the UPM at least ten times and the weight

conrmed using an electronic or mechanical scale. This is done

to ensure the cycling of the handle is consistent and dispensing

the metered charge accurately. If cycling of the handle is

inconsistent, there will be a variance in the dispensed charge

weight. Be sure to use the same uniform movements for each

metered charge. Depending upon handle orientation, raise or

lower the handle smoothly to the end of its rotation; this is the

ll position where the powder from hopper will ll the Metering

Cylinder. Leave the cylinder in this position briey to ensure

the Metering Cylinder is lled completely, especially for larger

dispense weights. If operation is too fast the cylinder may not

ll completely resulting in a lower than desired charge weight.

Lower or raise the handle smoothly to the end of its rotation

to dispense the metered powder charge. Provide a slight tap of

the handle to ensure all metered powder has been dispensed.

This is one technique, there are others that work just as well.

Use whichever technique works best for you and provides the

best results.

Powder type will inuence the accuracy of dispensed charges.

For example, Ball and Flake type powders will meter much

better and yield better accuracies than that of Extruded type

powders. If Extruded type powders are preferred, many powder

manufactures produce short cut Extruded powders which

meter much better in volumetric powder measures.

Powder should not be left in the Powder Measure for long

periods of time as it will deteriorate and may clog and jam the

Metering Cylinder it will also etch the Powder Hopper. By using the Drain Tube Attachment,

powder can be removed without removing the Powder Measure from stand. Ensure the

Metering Cylinder is rotated so that it is in the dispense position. Remove or loosen the Brass

Lock Screw to remove the Metering Screw assembly from the Cylinder. Insert the Drain Tube

attachment into the Metering Cylinder and install the Brass Lock Screw. Make sure the relief

on the Drain Tube attachment is positioned in line with the lock screw hole so the Lock Screw

will secure the Drain Tube in place. Rotate handle lowering the Drain Tube and empty powder

from Powder Measure. Make sure you have a container large enough to collect all powder

from hopper and position in front of Drain Tube while lowering as powder will begin owing

as soon as Drain Tube is lowered. When powder hopper has been emptied, the Hopper can be

removed, and any residual powder can be removed from powder measure.

Cylinder position when setting

for lightest load

Relief on Drain Tube

Dispense Position

Remove Metering

Screw Assembly

Inserting

Drain Tube

Attachment

Drain Tube

Attachment

Installed

Engraved Markings on Thimble

SETTING 2SETTING 1

SETTING 4SETTING 3

Reference Scale on Metering Screw

4

FIG. B

FIG. A

Next, rotate the Cylinder Bushing Assembly counterclockwise to reduce weight or rotate

clockwise to increase weight. If Cylinder Bushing is dicult to rotate loosen Brass Lock

Screw another 1/16th of a turn. When adjustment has been made and desired metered

powder charge is being dispensed, rotate Brass Lock Screw clockwise to secure Metering

Screw in place.

Note: be careful when setting metering screw for light

loads. The Metering Screw can be advanced all the way

in until it contacts the machined bore, when this is done

it needs to be advanced outward slightly, approximately

1/8-1/4 turn, to ensure there is adequate clearance

through entire range of the Metering Cylinder rotation.

When you meter powder, initially after setting up for light

load, you may nd that the Metering Cylinder binds up

and is dicult to rotate. If this happens simple loosen

the Brass Lock Screw and advance Metering Screw out

slightly until Metering Cylinder rotates freely. This will be

the lowest setting you will achieve with this powder type.

When setting up for light loads rotate Metering Cylinder

slightly so it is in the position shown (right). This ensures

the Metering Screw is not advanced passed the bore and

into the powder drop area of the casting.

The Metering Screw has a reference scale engraved

on the at portion of the Metering Screw (right). This

allows for recording the setting for a specic powder

type and charge weight being metered. This allows

for quicker setup during the next reloading session.

The Thimble on the Cylinder Bushing Assembly has

four dierent size engraved markings (below), each

marking is 90 degrees apart, to assist in recording

the powder setting. One complete turn of the

Cylinder Bushing will result in .050” of travel of the Metering Screw. Knowing how much the

metered charge will increase or decrease with one complete turn of the Cylinder Bushing will

aid in setting the UPM-3 for desired charge weight. Example: If metering Alliant 300 MP Ball

Powder and the Metering Screw is advanced outward by one rotation of the Cylinder Bushing,

the metered charge will increase by approximately 4.5 grains.

Before using UPM-3 to reload actual cartridges, we need to condition the Powder Measure,

to do this, set the powder measure for the maximum charge by rotating the Cylinder Bushing

Assembly clockwise, this will advance the metering screw outward until it reaches the end of

its travel. Fill the Hopper with powder and cycle UPM-3 until all powder has been metered and

dispensed. The UPM-3 holds approximately 1/2 pound of powder, so do this twice so a total of

one pound of powder has been metered through the Powder Measure. Doing this will deposit

a thin lm of graphite on the internal features allowing the powder to ow more evenly and

smoothly resulting in more consistent metered charges.

Checking the weight of the dispensed volumetric charge is very important and needs to be

done every time the UPM-3 is set up and used. This should also be done if the reloading session

is stopped and started at a later time. This can be done by weighing the dispensed volumetric

charge on either an electronic or mechanical scale.

Once the powder measure has been set, place the Screw Lock Ring, from Bag 3, onto the

Metering Screw and rotate clockwise until it makes contact with the Cylinder Bushing Assembly,

acting as a jam nut preventing any unwanted rotation of the Cylinder Bushing Assembly and

preventing any unwanted movement of Metering Screw. If the amount of powder being

dispensed needs to be adjusted, you will need to loosen the Screw Lock Ring prior to adjusting,

as shown in Figure A. Once the desired amount of powder dispensed is achieved re-tighten

the Screw Lock Ring as shown in Figure B. Cycle the UPM at least ten times and the weight

conrmed using an electronic or mechanical scale. This is done

to ensure the cycling of the handle is consistent and dispensing

the metered charge accurately. If cycling of the handle is

inconsistent, there will be a variance in the dispensed charge

weight. Be sure to use the same uniform movements for each

metered charge. Depending upon handle orientation, raise or

lower the handle smoothly to the end of its rotation; this is the

ll position where the powder from hopper will ll the Metering

Cylinder. Leave the cylinder in this position briey to ensure

the Metering Cylinder is lled completely, especially for larger

dispense weights. If operation is too fast the cylinder may not

ll completely resulting in a lower than desired charge weight.

Lower or raise the handle smoothly to the end of its rotation

to dispense the metered powder charge. Provide a slight tap of

the handle to ensure all metered powder has been dispensed.

This is one technique, there are others that work just as well.

Use whichever technique works best for you and provides the

best results.

Powder type will inuence the accuracy of dispensed charges.

For example, Ball and Flake type powders will meter much

better and yield better accuracies than that of Extruded type

powders. If Extruded type powders are preferred, many powder

manufactures produce short cut Extruded powders which

meter much better in volumetric powder measures.

Powder should not be left in the Powder Measure for long

periods of time as it will deteriorate and may clog and jam the

Metering Cylinder it will also etch the Powder Hopper. By using the Drain Tube Attachment,

powder can be removed without removing the Powder Measure from stand. Ensure the

Metering Cylinder is rotated so that it is in the dispense position. Remove or loosen the Brass

Lock Screw to remove the Metering Screw assembly from the Cylinder. Insert the Drain Tube

attachment into the Metering Cylinder and install the Brass Lock Screw. Make sure the relief

on the Drain Tube attachment is positioned in line with the lock screw hole so the Lock Screw

will secure the Drain Tube in place. Rotate handle lowering the Drain Tube and empty powder

from Powder Measure. Make sure you have a container large enough to collect all powder

from hopper and position in front of Drain Tube while lowering as powder will begin owing

as soon as Drain Tube is lowered. When powder hopper has been emptied, the Hopper can be

removed, and any residual powder can be removed from powder measure.

Cylinder position when setting

for lightest load

Relief on Drain Tube

Dispense Position

Remove Metering

Screw Assembly

Inserting

Drain Tube

Attachment

Drain Tube

Attachment

Installed

Engraved Markings on Thimble

SETTING 2SETTING 1

SETTING 4SETTING 3

Reference Scale on Metering Screw

4

FIG. B

FIG. A

Loading...

Loading...