Re S.p.A. US3

Rev.12/04/11 3/23

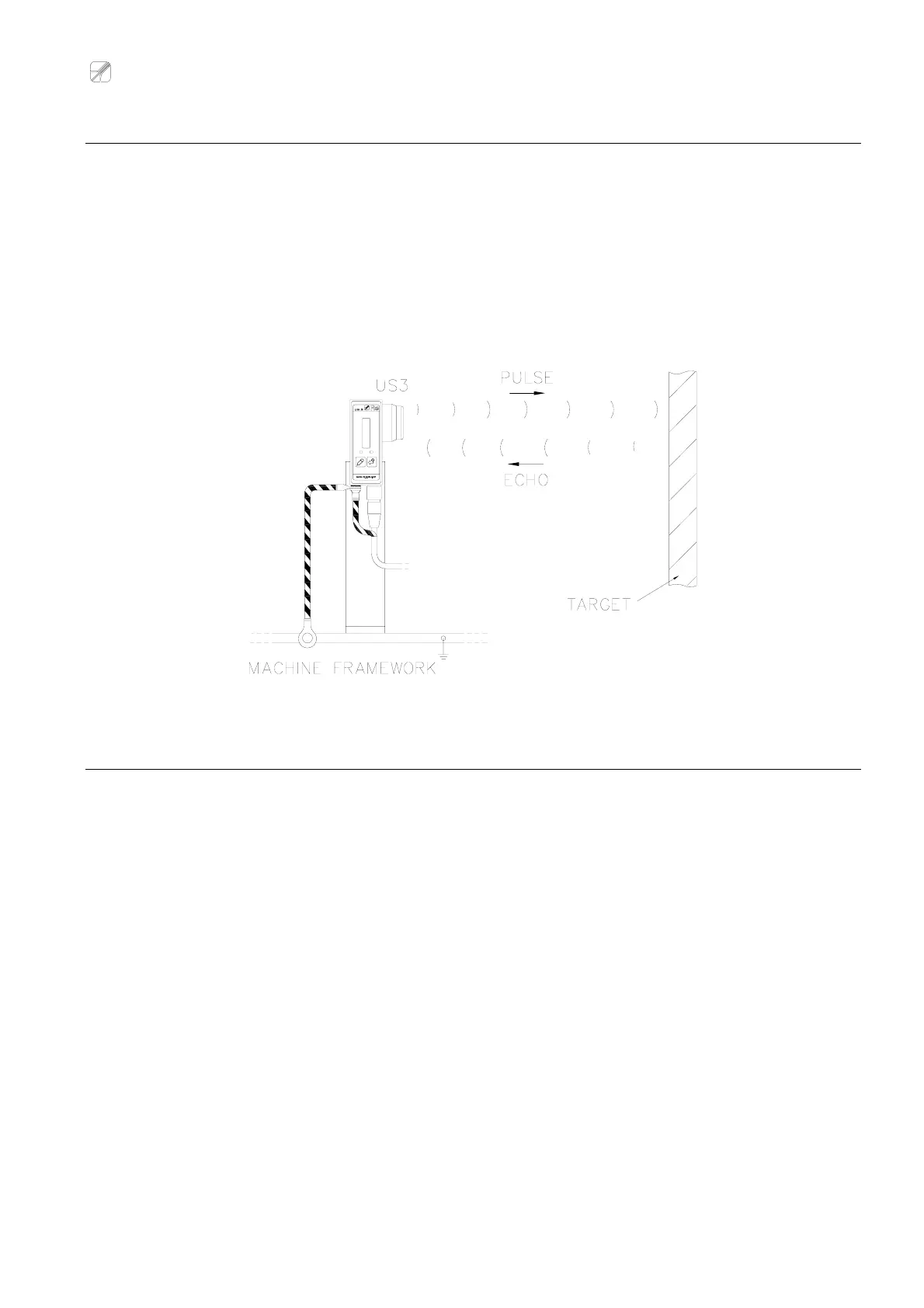

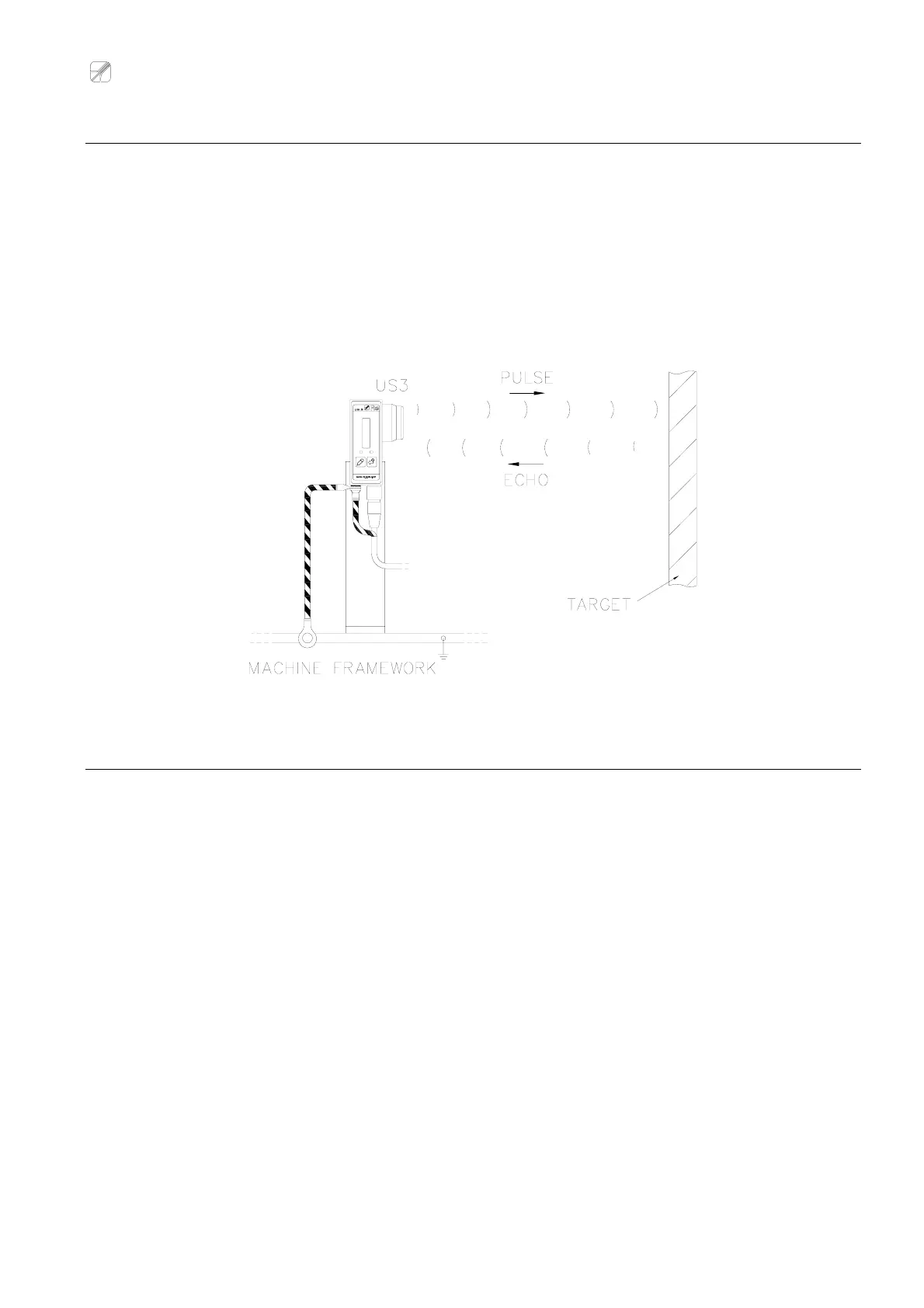

“Pulse-echo” measuring method

Every 100 milliseconds the US3 sensor emits an ultrasonic pulse at a frequency of 125kHz. The pulse

propagates in the air until it hits the target (positioned in front of the sensor) whose distance is to be

measured. The pulse is reflected (echo) by the object and picked up by the sensor which, based on the

time taken by the echo to return to the sensor and the sound propagation speed, calculates the distance

from the object.

After the pulse has been generated, the sensor is inhibited for a short time during which it cannot receive

the echo. This is a feature common to all “pulse-echo” sensors and defines the minimum distance which

can be measured.

Factors which influence measurement

Although ultrasonic sensors can operate in adverse environmental conditions, it is important to consider

several factors which affect measurement quality, so as to achieve the best possible performance:

The speed of the sound varies with the temperature, causing a measurement percentage error of

around 0.17%/°C. US3 has an internal temperature sensor which allows that error to be

compensated for automatically.

Big changes in temperature along the measuring path cannot be compensated for and may result in

sound diffraction and scattering.

Changes in atmospheric pressure do not affect measurements. We strongly advise against the use

of ultrasonic sensors in pressurised or vacuum environments, since there may be a significant

distortion in the reading.

The presence of nebulised liquids or powders in the air attenuates the sound, reducing the maximum

reading distance.

Draughts may divert the echo and prevent correct measurement.

Other ultrasound sources may overlap the echo, causing measurement errors.

Moisture may cause a temporary drop in reading sensitivity without damaging the sensor. Do not

allow ice to form on the surface of the sensor.

Small amounts of dust do not affect measurements. But it is important to keep the sensor clean. Do

not paint the surface of the ultrasonic capsule.

Clean the sensor with low pressure dry air.

Loading...

Loading...