6

•Install the servo to the hatch with the output

to the leading edge.

Then center

the servo

and install

the servo

horn.

•Place the hatch into the wing, pulling the servo

lead out to the root of the wing. The servo horn

should be toward the leading edge of the wing

and facing the fuselage, to line up with the

aileron control horn.

•With a 1/16” drill bit, drill for the servo screws

using the pre drilled holes in the hatch as a

guide.

From the Pro:

Use a piece of

tape to mark the

drill bit to help

avoid punching

through to the

top-side of the wing.

•Remove the hatch and thread a screw in and

out of each hole. Then apply 2 drops of thin CA

to each and allow the CA to soak in and fully

cure. Once cured you can install the hatch and

servo for the

final time.

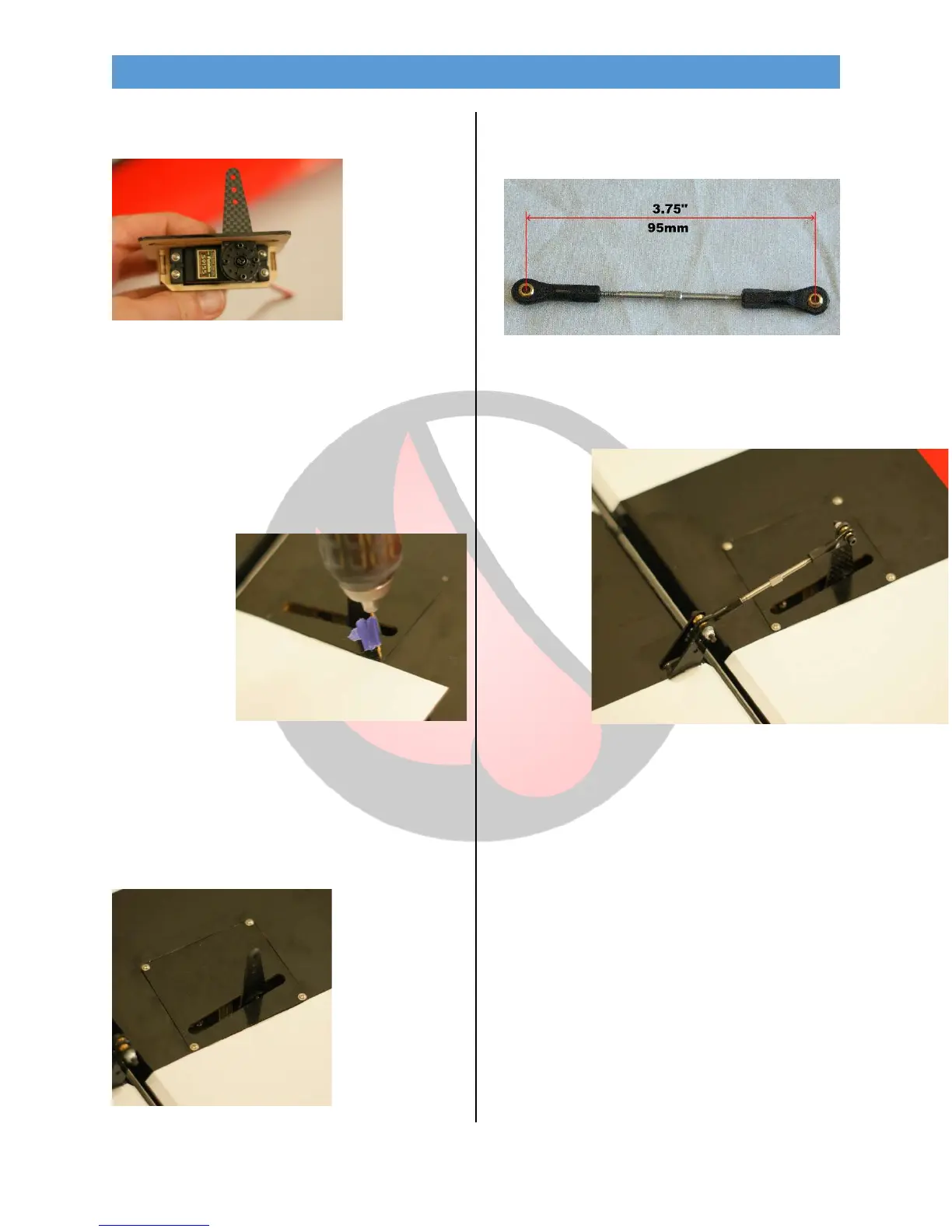

•Assemble the control rods to 3.75” length

making sure the turnbuckle is centered with

room to adjust both ends.

NOTE: These are a true turnbuckle and one end

is reverse thread.

• Install the pushrod with the included

hardware.

From the Pro: It is essential that you install the side

with the standoff toward the control horn and use a

small washer on the outside of the ball link. This will

prevent the ball joint from slipping off under load.

Loading...

Loading...