25

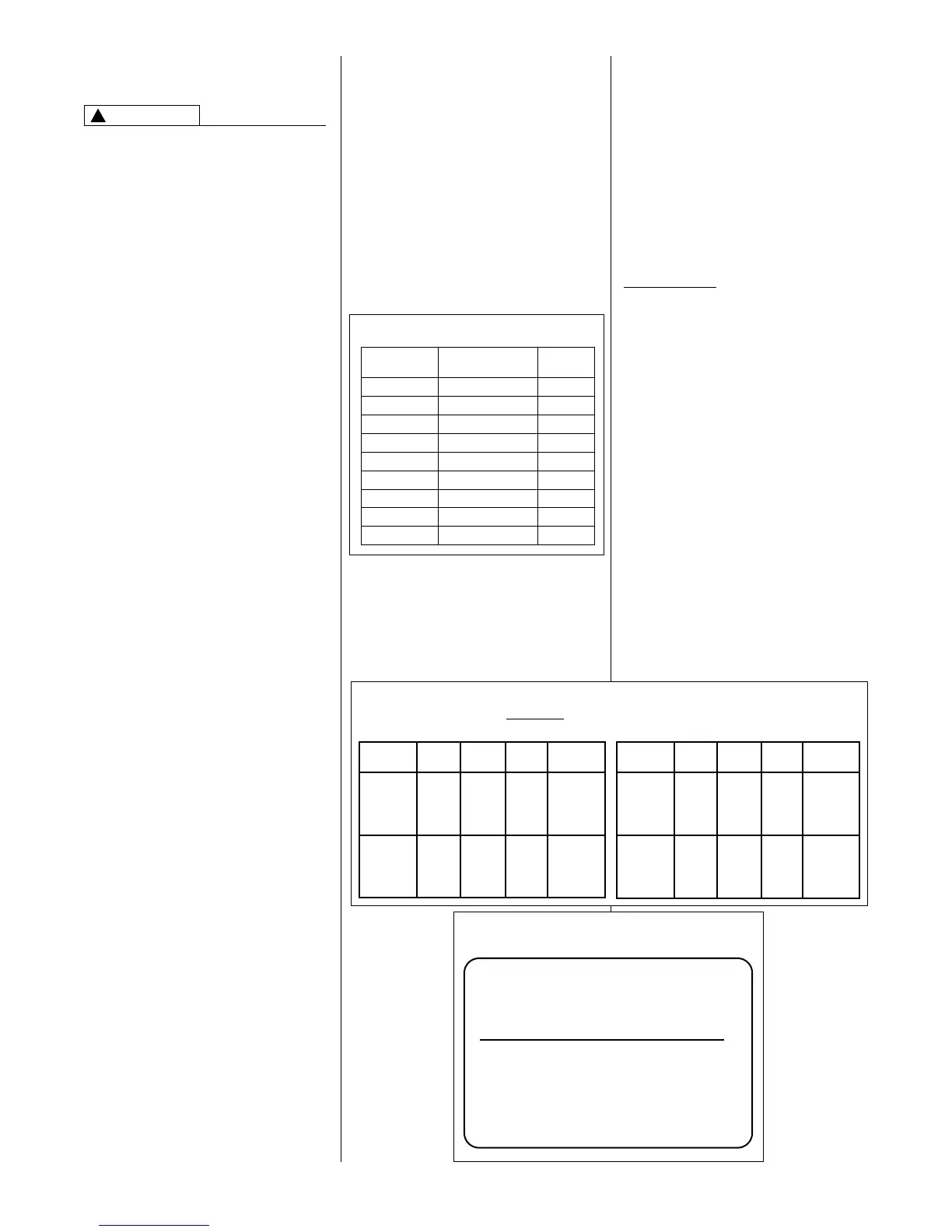

ORIFICE ORDERING

INFORMATION

Orifice sizes are selected by adding the

2-digit drill size required in the orifice

part number. Drill sizes available are 39

through 64; metric sizes available

1.10mm (-90) and 1.15mm (-91):

Orifice Part Number 62-22175-(drill size)

Example 1:

# 60 drill size orifice required

Part # 62-22175-60

Example 2:

1.15mm drill size orifice required

Part # 62-22175-91

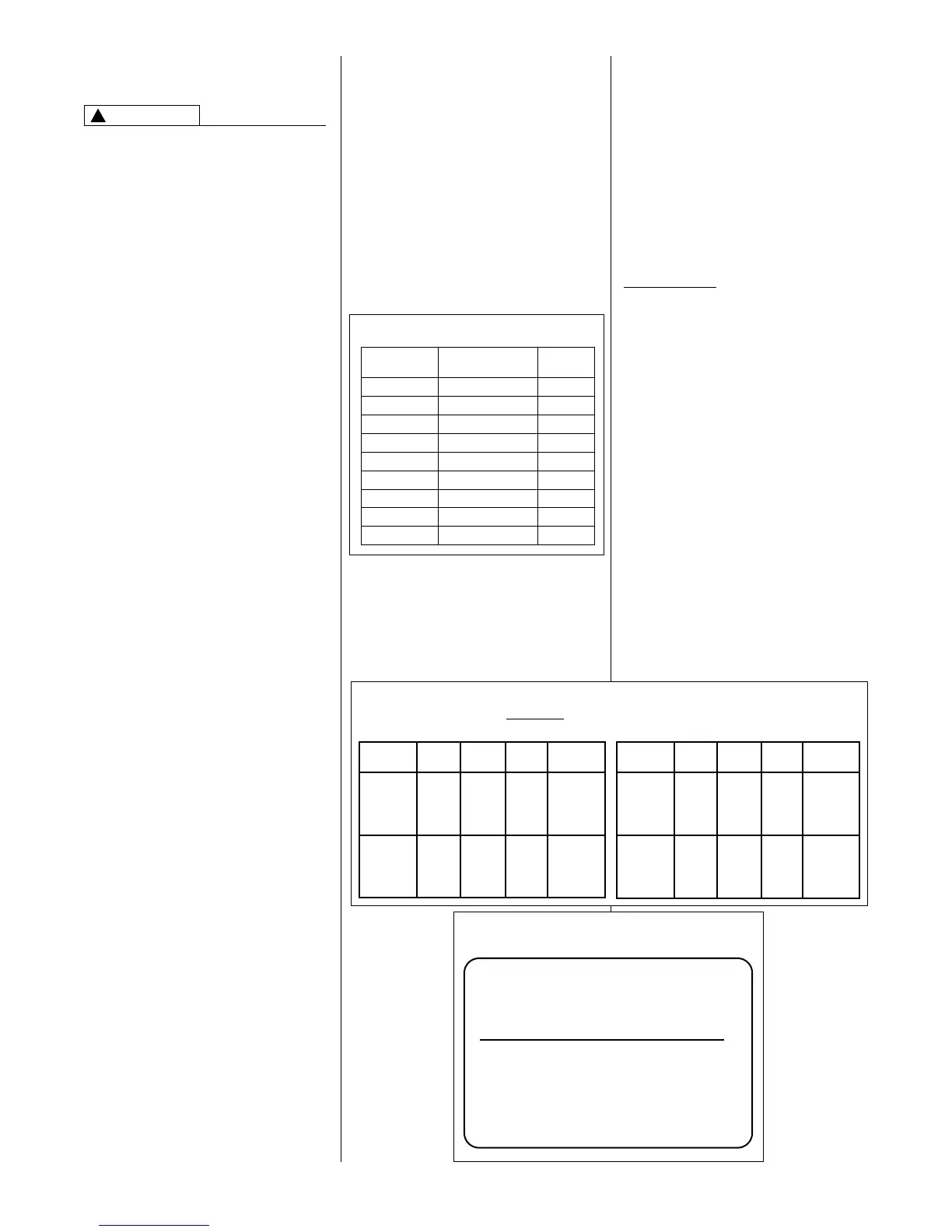

ALTERNATE METHOD FOR

CANADIAN

HIGH-ALTITUDE

DERATE

In Canada, unless an orifice change is

specifically mandated by local codes,

an alternate method of altitude deration

through a reduction in manifold

pressure is acceptable as described in

Table 8. This information is based on a

heating value of 1000 BTU per cubic

feet of natural gas, and 2500 BTU per

cubic feet of LP gas.

IMPORTANT: Actual input rates must

be measured onsite with manifold

pressure adjustment to ensure that an

actual 10% reduction in input rate is

achieved.

Once this field adjustment has been

made, the label shown in Figure 19

must be affixed in a conspicuous

location on the front of the furnace

cabinet.

NOTE: This label is supplied in the

information packet shipped with each

furnace.

TABLE 8

ALTERNATE METHOD FOR CANADIAN HIGH-ALTITUDE DERATE

IMPORTANT: 80+ MODELS ONLY! DO NOT USE THIS CHART WITH ANY 90+ MODELS.

NATURAL GAS LP GAS

ALTITUDE

INPUT

OUTPUT

ORIFICE

SIZE

MANIFOLD

PRESSURE

0’ - 2000’

50,000

75,000

100,000

125,000

150,000

40,000

60,000

80,000

100,000

120,000

#42

3.5” W.C.

2001’ - 4500’

45,000

67,500

90,000

112,500

135,000

36,000

54,000

72,000

90,000

108,000

#42

2.9” W.C.

ALTITUDE

INPUT

OUTPUT

ORIFICE

SIZE

MANIFOLD

PRESSURE

0’ - 2000’

50,000

75,000

100,000

125,000

150,000

40,000

60,000

80,000

100,000

120,000

#54

10” W.C.

2001’ - 4500’

45,000

67,500

90,000

112,500

135,000

36,000

54,000

72,000

90,000

108,000

#54

8.1” W.C.

Loading...

Loading...