25

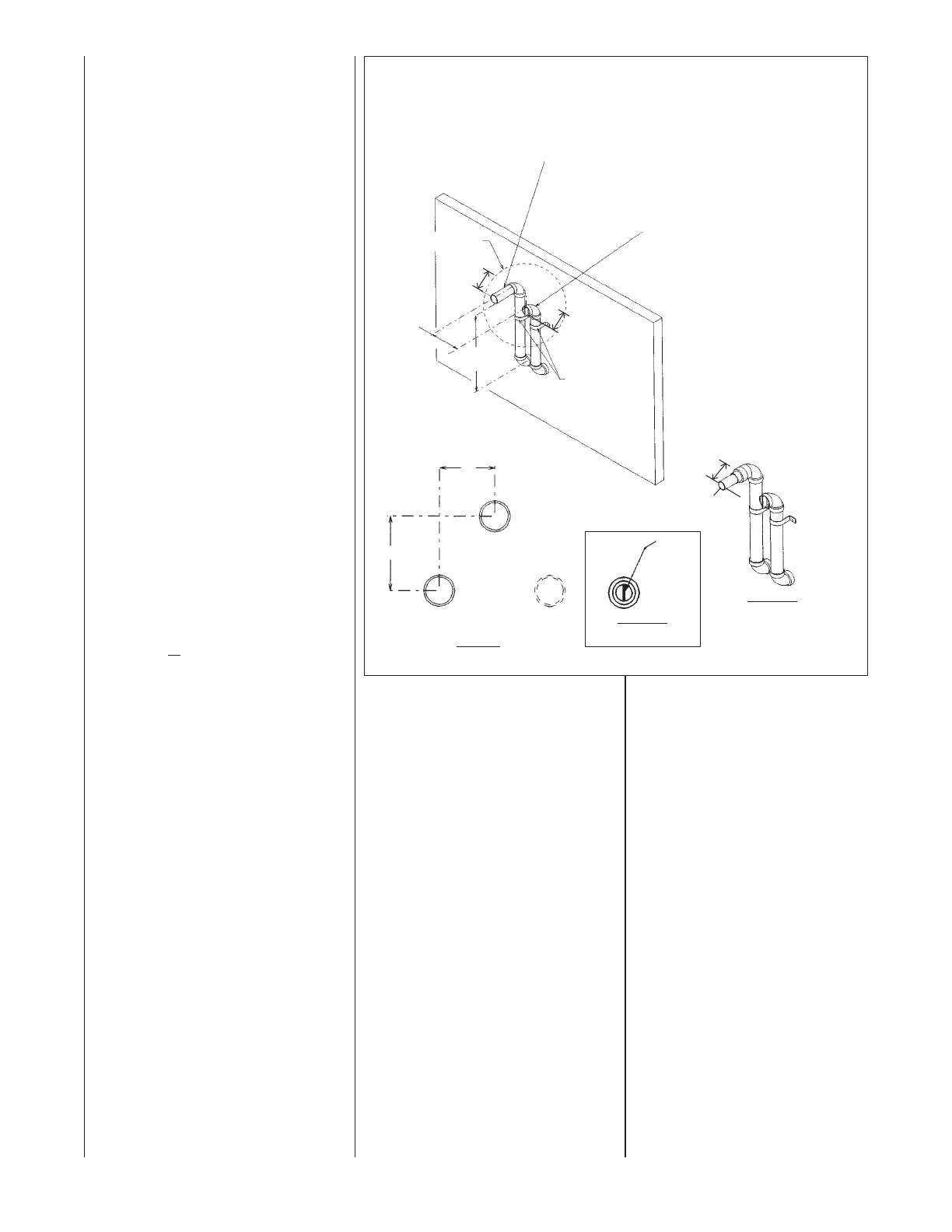

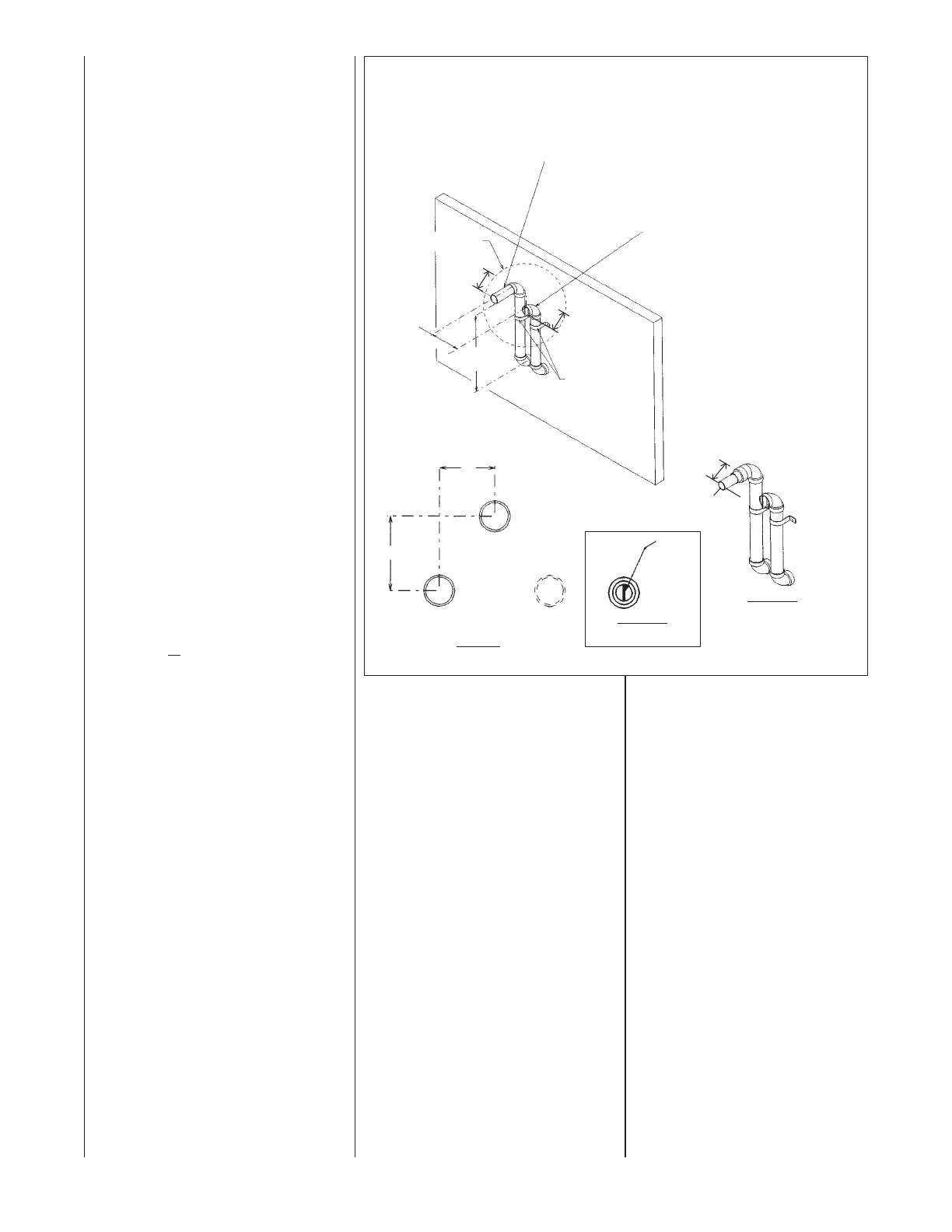

FIGURE 17

ALTERNATE HORIZONTAL DIRECT VENT TERMINATION

SEE DETAIL A

24” MAX.

PIPE

SUPPORT

STRAP

3” MAX.

NOTE: 3-1/2”

MAX. WHEN

D04 KIT IS

USED.

EXHAUST VENT

2

1

/2" PVC FOR MODELS WITH 120,000 BTU INPUT

(KIT NO. (-)XGY-D04)

2" PVC FOR MODELS WITH INPUTS OF 90,000 AND

120,000 BTU. REDUCE TO 1

1

/2" FOR MODELS WITH

INPUTS OF 45,000 THRU 75,000 BTU (SEE DETAIL A).

ELBOWS AND RISERS ARE 2" PVC.

INTAKE VENT

2

1

/2" PVC FOR MODELS WITH

120,000 BTU INPUT.

2" PVC ELBOWS AND RISER

MODELS WITH INPUTS OF 45,000

THRU 105,000 BTU.

USE KIT NO. (-)XGY-D02/D02A WHEN 2"

PIPE IS USED BETWEEN FURNACE AND

OUTSIDE WALL. USE KIT NO. (-)XGY-

D03/D03A WHEN 3" PIPE IS USED.

I339

• Insulate the entire length of vent

pipe, between the elbow where the

pipe exits the wall and the elbow

where the termination is made, with

a closed-cell insulation, such as

“Arm-a-Flex” or “Rub-a-Tex” with a

minimum of 1/2” thickness.

• All elbows installed on the exterior

of the building must be of the long

sweep nature.

• As required for the horizontal piping

ran within the structure, any pipe

ran horizontal outside the structure

must slope upward a minimum of

1/4” per foot run so that condensate

drains toward the furnace.

From the top elbow in the exhaust

pipe, extend a length of PVC pipe

outward so that it terminates exactly

12 inches from the wall. See Figure

17. Reduce the exhaust pipe

extension to is 1

1

⁄2 inch pipe for

45,000 BTUH through 75,000 BTUH

units.

The 45,000 BTUH unit only uses kit

(-)XGY-D02/D02A. The 60,000 BTUH

and 75,000 BTUH downflow only

units may use kits (-)XGY-D02/D02A

or (-)XGY-D03/D03A depending on

pipe lengths and number of elbows.

Use kit (-)XGY-D03/D03A with 90,000

BTUH downflow through 120,000

BTUH units or

upflow 90,000 or

120,000. The (-)XGY-D04/D04A kit

only applies to the 120,000 BTUH

unit using an alternate termination

and excessively long runs. See

Table 4.

The following are parts lists for the

(-)XGY-D02/D02A, (-)XGY-D03/D03A

and (-)XGY-D04/D04A alternate

horizontal direct vent termination kits:

(-)XGY-D02/D02A

1. 2-in. tee with reducer assembly

2.

1

⁄2-in. PVC 6-in. dia. trap

3. PVC vane

4. 2-in. PVC elbow

5. 1

1

⁄2-in. PVC nipple with coupling

6. PVC strap

7. vent template

(-)XGY-D03/D03A

1. 3-in. tee with reducer assembly

2.

1

⁄2-in. PVC 6-in. dia. trap

3. PVC vane

4. 2-in. PVC elbow

5. PVC strap

6. vent template

(-)XGY-D04/D04A

1. 2

1

⁄2-in. PVC elbow

2. 3" x 2

1

⁄2" PVC bushing

3. 2

1

⁄2" x 6

1

⁄2" long PVC pipe

4. 2

1

⁄2" x 16" long PVC pipe

5. 2

1

⁄2" x 21" long PVC pipe

6. PVC vane

7.

3-in. tee with reducer assembly

8. 6-in. dia.

1

⁄2-in. PVC trap

9. PVC strap

10. vent template

NOTE: The (-)XGY-D04/D04A kit only

applies to the 120,000 BTUH unit

using an alternate termination and

excessively long runs.

3”

4”

EXHAUST

VANE

INTAKE

OPTIONAL

INTAKE

DETAIL B

EXHAUST / INTAKE RELATIONSHIP

DETAIL A

EXHAUST VENT FOR

MODELS WITH

INPUT OF 45,000 THRU

75,000 BTU

DETAIL C

COMBUSTION AIR

TERMINATION

4" FROM

WALL

12"

FROM

WALL

1-1/2"

PIPE

12" FROM

WALL

(-)XGY-D02A

1. 2” Tee assembly w/

1

⁄2” drain

connection

2.

1

⁄2” PVC-5” diameter trap

3. Wind deflector vane

4. Vent template

(-)XGY-D03A

1. 3” Tee assembly w/

1

⁄2” drain

connection

2.

1

⁄2” PVC-5” diameter trap

3. Wind deflector vane

4. Vent Template

(-)XGY-D04A

1. 3” Tee assembly w/

1

⁄2” drain

connection

2.

1

⁄2” PVC-6” diameter trap

3. Wind deflector vane

4. Vent template

Loading...

Loading...