39

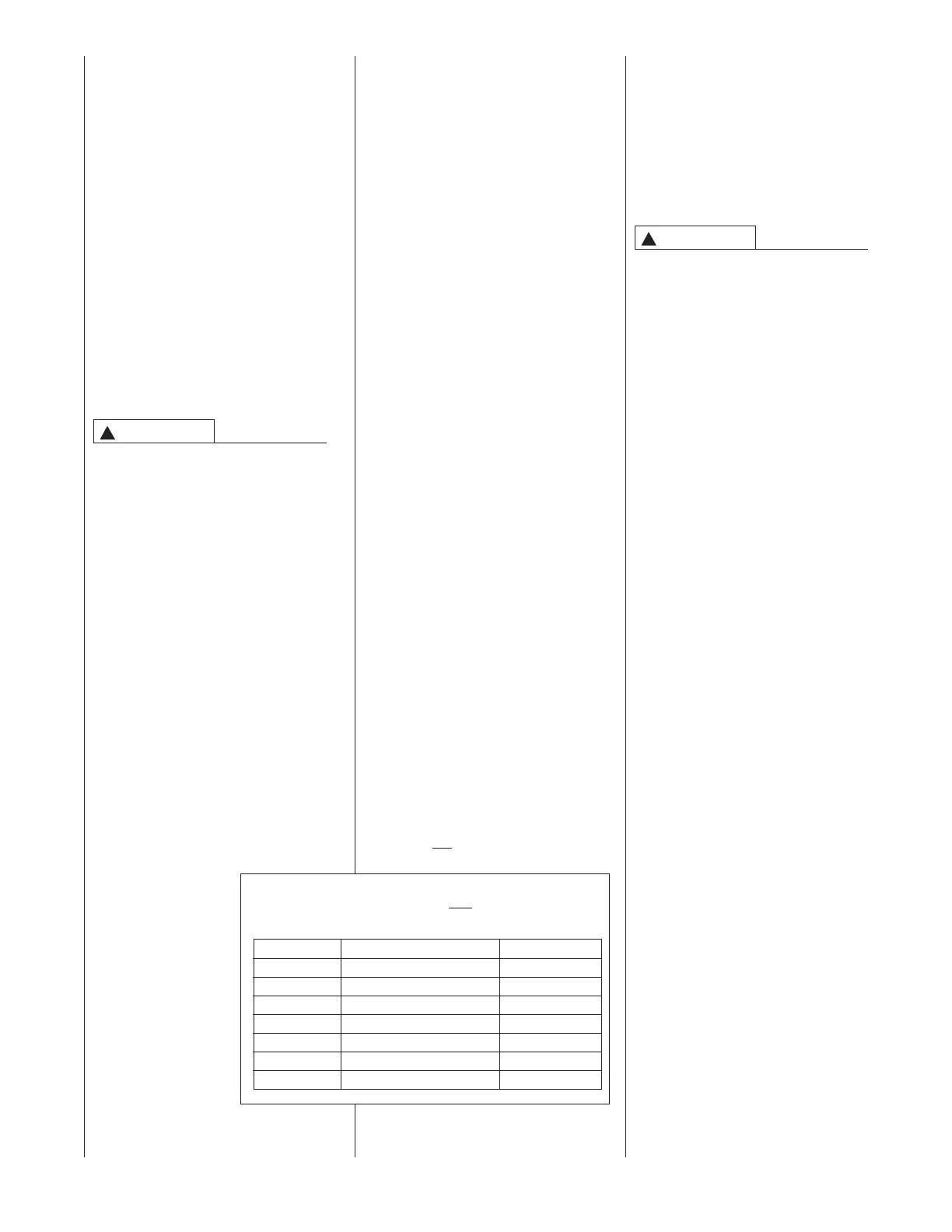

TABLE 7

IMPORTANT: 90+ MODELS ONLY. DO NOT USE THIS CHART

FOR ANY 80 PLUS MODELS.

LP GAS ORIFICE DRILL SIZE (4% PER 1000 FT DE-RATE)

LP CONVERSION

IMPORTANT: LP gas from trucks

used to transport liquid-based

fertilizers can contain chemicals that

will damage the furnace. Verify that

your gas supplier does not use the

same truck to transport materials

other than LP.

For LP conversion, a new gas valve is

required. The new gas valve is

included in the LP kit. The correct LP

orifices should be selected based on

the altitude of the installation (see

chart below). Orifices included in the

kit are for sea level to 2000 ft.

(1.15mm) and 3000 to 4000 ft.

(1.10mm) The LP Gas Valve Kit is

FP19. Orifices for elevations 4000 ft.

and above must be ordered. Refer to

Table 7.

ELEVATIONS ABOVE 2000 FT

REQUIRE THAT THE FURNACE

INPUT RATING BE ADJUSTED

AND THAT THE SIZE OF THE

BURNER ORIFICES BE RE-

CALCULATED BASED ON

ELEVATION AND GAS HEATING

VALUE. THE BURNER ORIFICES

MAY (OR MAY NOT) NEED TO BE

CHANGED. SEE THE SECTION

TITLED “HIGH ALTITUDE

INSTALLATIONS” OF THIS BOOK

FOR INSTRUCTIONS.

NOTE: Furnace conversion to LP gas

must be performed by a qualified

installer, service agency or the gas

supplier.

To change the gas valve and orifice

spuds for either conversion to LP or for

elevation:

1. Shut off the manual main gas valve

and remove the gas manifold.

2. Replace the orifice spuds.

3. For LP conversion ONLY, Remove

the gas valve.

4. Reassemble in reverse order. In

LP applications, use the new gas

valve provided in the LP

conversion kit.

5. Attach the notice label alerting the

next service technician that the

furnace has been converted to LP

gas.

6. Turn the gas supply back on and

check for proper operation, leaks

and manifold pressure. See

Figures 37 and 39.

NOTE: Orifices in the kit are sized for a

heating value of 2500 BTU per cubic ft.

for LP.

ORIFICE ORDERING

INFORMATION

Orifice sizes are selected by adding the

2-digit drill size required in the orifice

part number. Drill sizes available are 39

through 64; metric sizes available

1.10mm (-90) and 1.15mm (-91):

Orifice Part Number 62-22175-(drill

size)

Example 1:

# 60 drill size orifice required

Part # 62-22175-60

Example 2:

1.15mm drill size orifice required

Part # 62-22175-91

NOTE: Do not

plug or drill out orifices.

Altitude BTU Input (per burner) 15000 Orifice Size

0 to 2000 ft. 15000 1.15 mm (factory)

2001 to 3000 13200 1.15 mm

3001 to 4000 12600 1.10 mm

4001 to 5000 12000 #58

5001 to 6000 11400 #59

6001 to 7000 10800 #60

7001 to 8001 10200 #62

SETTING GAS PRESSURE

The maximum gas supply pressure

to the furnace should be 10.5" w.c.

natural gas, or 13" w.c. LP gas. The

minimum supply gas pressure to the

gas valve should be 5" w.c. natural

gas or 11" w.c. LP gas. A properly

calibrated U-Tube manometer is

required for accurate gas pressure

measurements.

ELEVATIONS ABOVE 2000 FT

REQUIRE THAT THE FURNACE

INPUT RATING BE ADJUSTED

AND THAT THE SIZE OF THE

BURNER ORIFICES BE RE-

CALCULATED BASED ON

ELEVATION AND GAS HEATING

VALUE. THE BURNER ORIFICES

MAY (OR MAY NOT) NEED TO BE

CHANGED. SEE THE SECTION

TITLED “HIGH ALTITUDE

INSTALLATIONS” OF THIS BOOK

FOR INSTRUCTIONS.

Supply Gas Pressure Measure-

ment. A line pressure tap is on the

input side of the gas valve. See

Figure 37.

1. With gas shut off to the furnace

at the manual gas stop outside

the unit, remove the input

pressure tap plug.

2. Connect a U-Tube manometer to

the pressure tap.

3. Turn on the gas supply and

operate the furnace and all other

gas-fired units on the same gas

line as the furnace.

4. Note or adjust the line gas

pressure to give:

A. 5" - 10.5" w.c. for natural gas.

B. 11" - 13" w.c. for LP gas.

5. Shut off the gas at the manual

gas stop and remove the

U-Tube manometer.

6. Replace the pressure tap plug

before turning on the gas. Turn

on gas and check for leaks.

If the supply gas line pressure is

above these ranges, install an in-line

gas regulator to the furnace for

natural gas units. With LP gas, have

the LP supplier reduce the line

pressure at the regulator.

If supply gas line pressure is below

these ranges, either remove any

restrictions in the gas supply piping or

enlarge the gas pipe. See Tables 6

and 8. With LP gas, have the LP

supplier adjust the line pressure at

the regulator.

CAUTION

!

CAUTION

!

Loading...

Loading...