40

TABLE 8

LP GAS PIPE CAPACITY TABLE (CU. FT./HR.)

Maximum capacity of pipe in thousands of BTU per hour of undiluted liquefied petroleum gases (at 11 inches water

column inlet pressure).

(Based on a Pressure Drop of 0.5 Inch Water Column)

Nominal Length of Pipe, Feet

Iron Pipe

Size, Inches 10 20 30 40 50 60 70 80 90 100 125 150

1/2 275 189 152 129 114 103 96 89 83 78 69 63

3/4 567 393 315 267 237 217 196 182 173 162 146 132

1 1,071 732 590 504 448 409 378 346 322 307 275 252

1-1/4 2,205 1,496 1,212 1,039 913 834 771 724 677 630 567 511

1-1/2 3,307 2,299 1,858 1,559 1,417 1,275 1,181 1,086 1,023 976 866 787

2 6,221 4,331 3,465 2,992 2,646 2,394 2,205 2,047 1,921 1,811 1,606 1,496

Example (LP): Input BTU requirement of unit, 120,000

Equivalent length of pipe, 60 ft. = 3/4" IPS required.

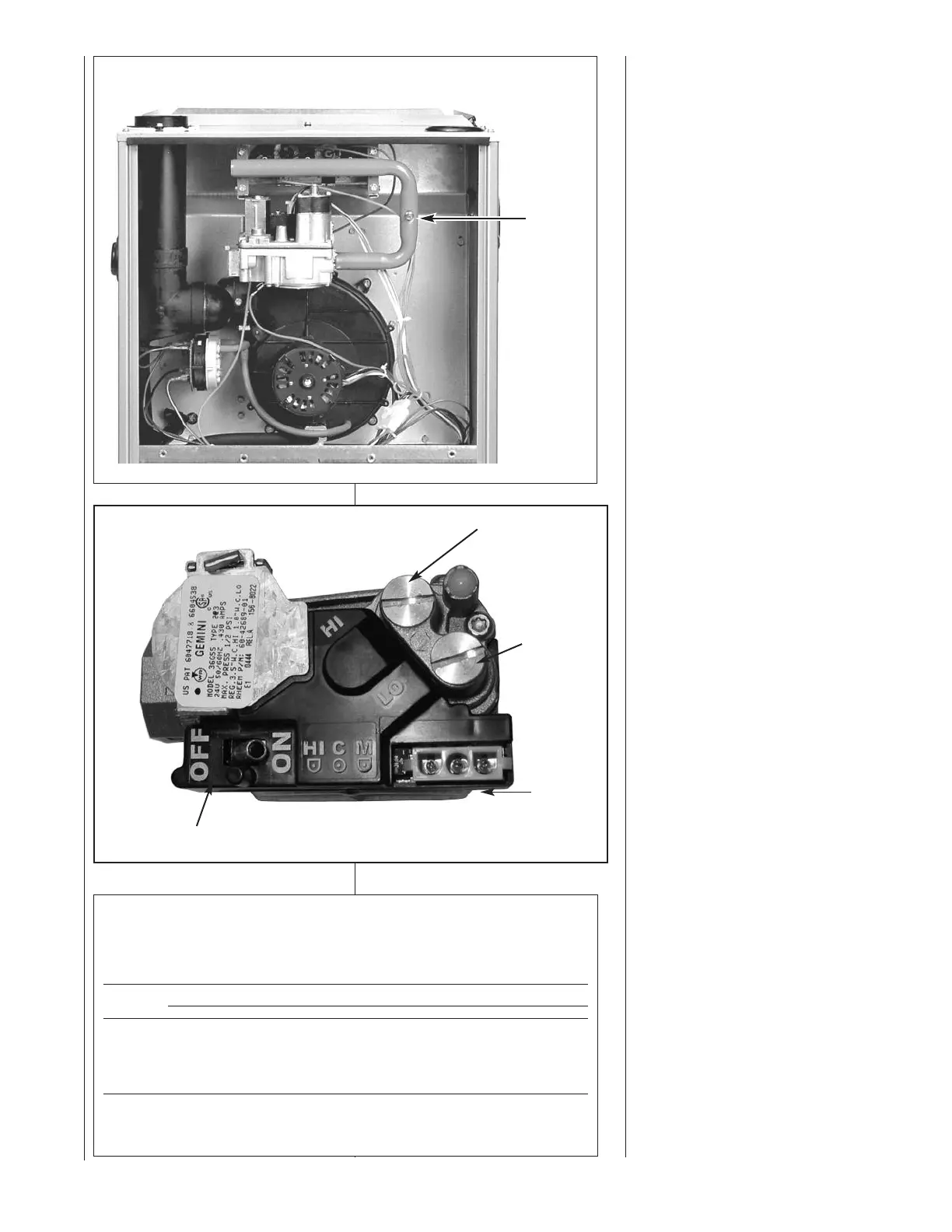

FIGURE 37

MANIFOLD PRESSURE TAP

Manifold Gas Pressure

Measurement. Natural gas

manifold pressure should be 3.5"

w.c.; LP gas manifold pressure

should be 10" w.c. Only small

variations on gas pressure should be

made by adjusting the pressure

regulator.

1. With the gas shut off at the

manual gas stop, remove the

pressure tap plug in the gas

manifold or the gas valve outlet.

See Figure 37.

2. Connect a U-Tube manometer to

this pressure tap. See Figure 39.

3. Turn on the gas supply and

operate the furnace in high heat

mode.

4. Note or adjust the manifold gas

pressure to give:

A. 3.5" w.c. for natural gas high

fire.

B. 10" w.c. for LP gas high fire.

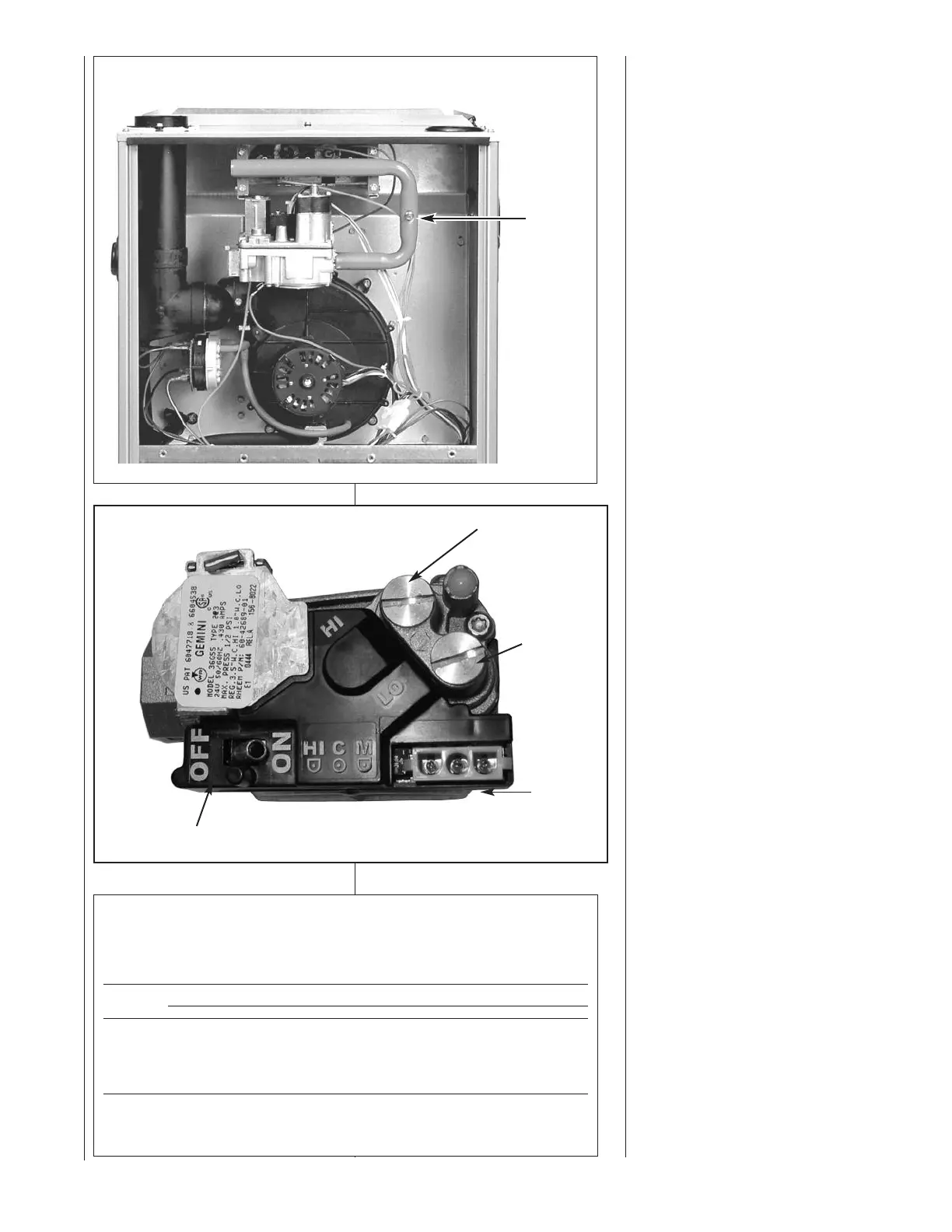

5. To adjust the pressure regulator

for high fire, remove the regulator

cap located on the side of the

regulator. See Figure 38.

6. Turn the adjustment screw

clockwise to increase pressure or

counterclockwise to decrease

pressure.

7. Securely replace the regulator

cap for high fire.

8. Operate the furnace in low

speed.

9. Note or adjust the manifold

pressure to give:

A. 1.7" w.c. for natural gas low

fire.

B. 4.8" w.c. for LP gas low fire.

10. To adjust the pressure regulator

for low fire, remove the regulator

cap on the top of the regulator.

See Figure 38.

11. Turn the adjustment screw

clockwise to increase pressure or

counterclockwise to decrease

pressure.

12. Securely replace the regulator

cap for low fire.

13. Verify pressures for high and low

fire operation.

14. Shut off gas at the manual gas

valve and remove the U-Tube

manometer.

15. Replace the manifold pressure

tap plug before turning on gas.

Check for leak.

MANIFOLD

PRESSURE

TAP

FIGURE 38

TYPICAL GAS VALVE

INLET

PRESSURE TAP

OUTLET

PRESSURE

TAP

HIGH FIRE

MANIFOLD

PRESSURE

ADJUSTMENT

LOW FIRE

PRESSURE

MANIFOLD

ADJUSTMENT

Loading...

Loading...