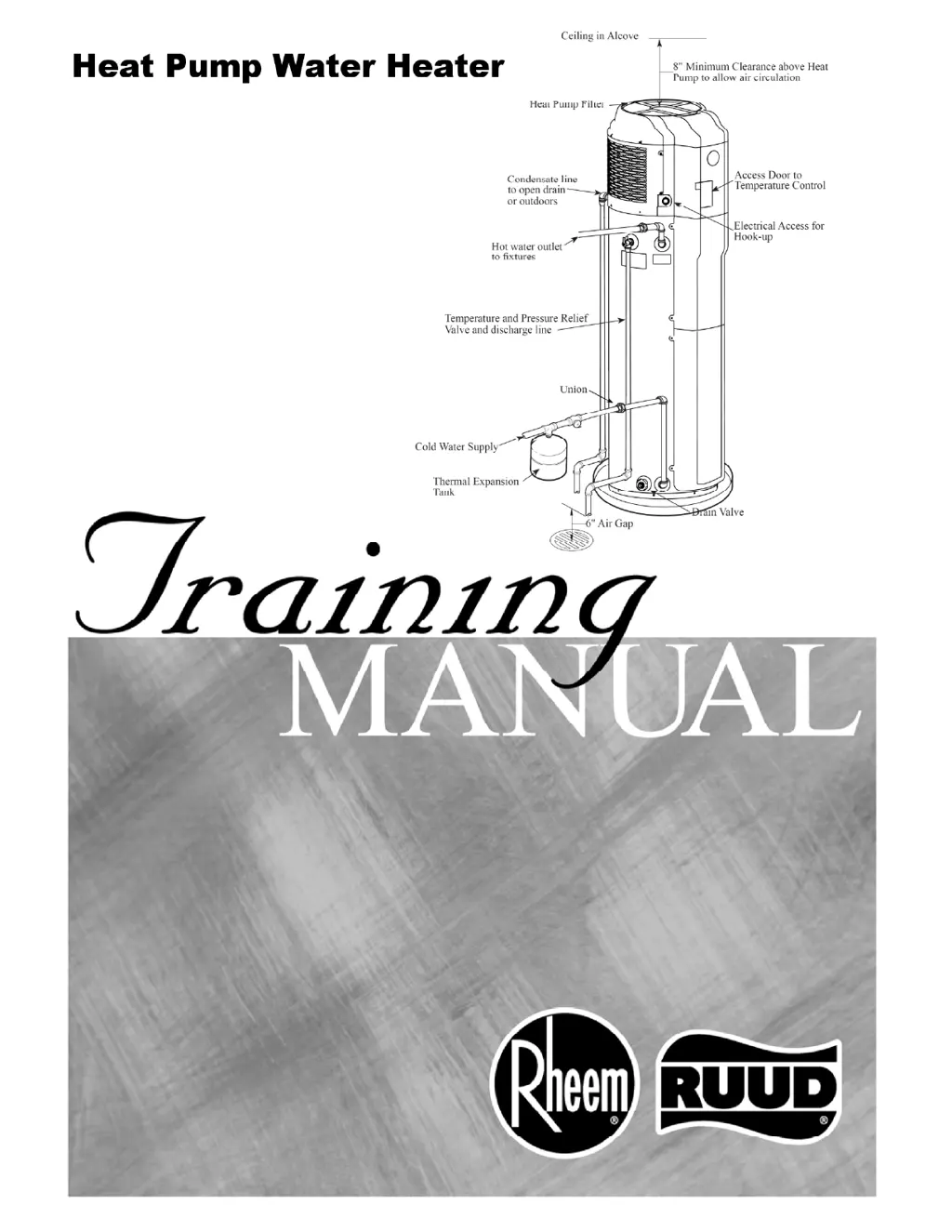

What to do if my Rheem RUUD Iraining compressor will not run?

- JJoshua PerezAug 5, 2025

If the compressor will not run, first turn the unit ON. Then, check the wiring against the diagram and reset the breaker. Verify the voltage. If these steps don't solve the problem, consider replacing the water heater.