II 1

The lens of the Rhino “Large View” Welding Helmet typically has double the view-

ing area of a standard helmet. As a result of the increased size, more care needs to

be taken with the helmet because the lens is a LCD made of glass, similar to many

television and cell phone screens manufactured today. If the helmet is acciden-

tally dropped onto a hard surface or smashed, the lens can crack or shatter .

Place the helmet in a bag or box after use. Ambient lighting in a shop, garage, or

workplace can activate the lens, but not provide enough solar energy for power,

which will employ the batteries to keep the lens activated. Over a long period of

time this can drain the batteries. Storage in a bag or box will eliminate this pos-

sibility. Replacement CR2025 batteries are available at a very low cost from most

stores and online. Instructions for battery installation are pictured and described

later in this manual.

If you would like to test your helmet before use, then please do the following:

1. Turn the lens sensitivity to “MAX”

2. Position the helmet with the lens facing a light bulb with a minimum of

60-Watts. To insure an accurate test, the helmet must be within 12 inches of the

light bulb. Equivalent and brighter light sources can be substituted.

3. If the lens does not darken, check/replace the (2) CR2025 batteries and retest.

1.2 Customer Care & Warranty Inquiries - Welding Helmets Direct

Please check your helmet and lens for any damage that may have occurred during

shipping and notify us immediately. If you experience any problems, we are here

to help. Helmets carry a 2-year warranty. Warranty inquiries are handled by our

customer care department.

Customer Care Department:

customercare@weldinghelmetsdirect.com

Welding Helmets Direct

PO Box 8628

Bend, OR 97708

Phone: (541) 749-0903 Toll Free: (855) 207-9865

1.1 Important Information

Section 1 - Required Reading - Important Points and Safety

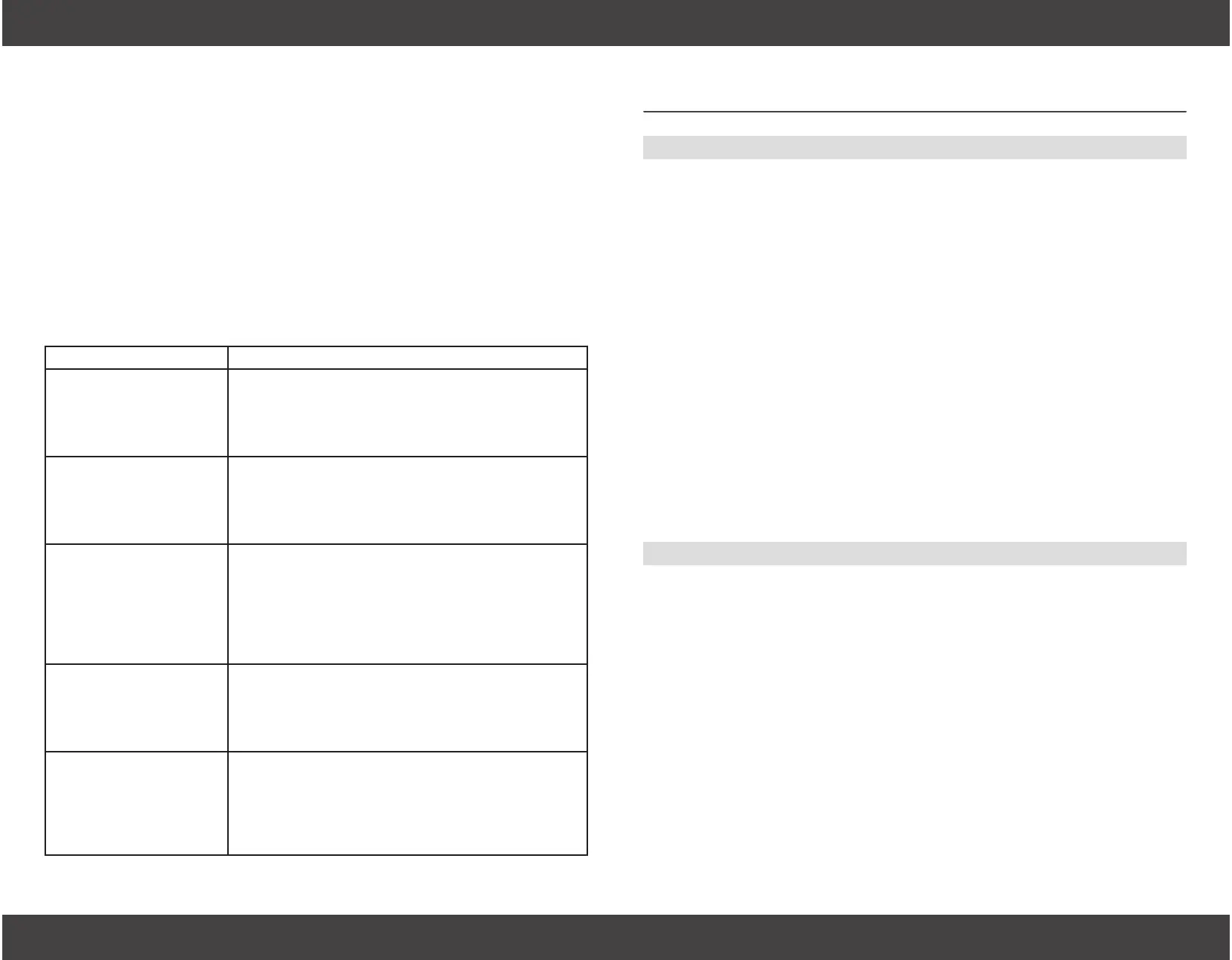

Table of Contents & Common Troubleshooting.......................................

Section 1 - Required Reading - Important Points and Safety..............

Section 2 - Headgear Assembly Components and Installation...........

Section 3 - Adjusting Headgear......................................................................

Section 4 - Lens Cover Replacement.............................................................

Section 5 - Variable Shade, Sensitivity, and Delay Adjustment............

Section 6 - Battery Replacement....................................................................

Below

1-2

3-5

6

7

8-9

10

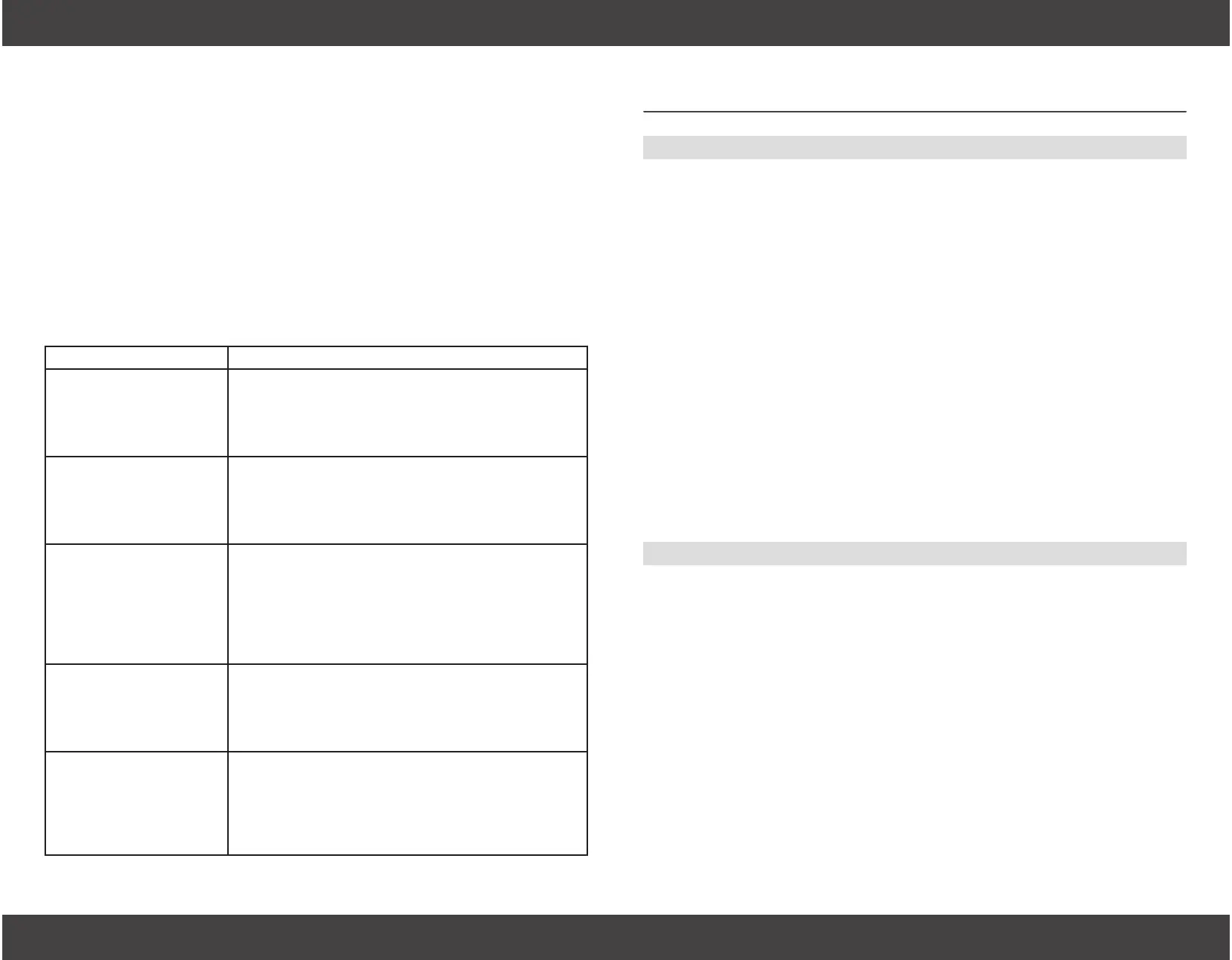

Problem Solution

Auto-darkening lens stays

in light state when welding,

does not darken.

STOP WELDING! Adjust lens sensitivity to higher setting.

Change exterior lens cover if it is dirty or damaged. Make

sure there are no obstructions between arc and sensors,

extreme angles will obstruct the arc from sensors. Possible

dead batteries, replace with two CR2025 lithium batteries.

Auto-darkening lens stays in

dark state after the welding

arc is gone or the lens stays

dark when no welding arc is

present.

Adjust the sensitivity setting lower with small changes,

gradually moving it towards low. In some light conditions

where lots of ambient light exists, reduction of ambient light

may be necessary with barriers or other blocking devices.

Areas of the auto-darkening

lens are not darkening; lines

separate light and dark areas

of the lens.

STOP WELDING! The auto-darkening lens may contain a

crack, which can be caused from the impact of the helmet

being dropped or smashed. Weld spatter on the lens can

also cause a crack. The lens needs to be replaced; this is not

covered under warranty in most cases, email customer care

at customercare@weldinghelmetsdirect.com to nd out how

we can help you.

Auto-darkening lens is

ickering when welding arc is

present.

Adjust the sensitivity setting to a higher level. Change exte-

rior lens cover if it is dirty or damaged. Make sure there are

no obstructions between arc and sensors, extreme angles

will obstruct the arc from sensors. Reduce the delay setting

to minimum.

Variable lighter auto-dark-

ening lens shading in the

dark state, noticeable on the

outside edges and corners

of lens.

Called “angle of view eect,” auto-darkening lenses have an

optimum viewing angle of operation. That angle is per-

pendicular to the surface of the lens or 90 degrees. This is a

normal behavior of the lens and does not reveal a health or

safety hazard. Cheater lenses or magnifying lenses enable

this eect to become more noticeable.

Help@RhinoWeldingHelmets.com

Loading...

Loading...