21

21

GG

BB

POINT B -

SETTINGS

DIP 1 (ON) MOTOR ROTATION DIRECTION CHECK

(See Point C

)

DIP 2 (ON) PROGRAMMING (See Point D)

DIP 1-2 STORING/ERASING RADIO CODES FOR

MOTOR CONTROL (only CRX control board) (See Point G,

H and I)

DIP 2-1 PROGRAMMING OF THE PEDESTRIAN OPENING (See

Point F)

DIP 3 ON - Automatic Closing ENABLED

OFF - Automatic Closing DISABLED

DIP 4 ON - Photocells active only in closing

OFF - Photocells always active

DIP 5 ON - blinker pre-flashing

OFF - blinker normal-flashing

DIP 6 ON - STEP BY STEP

Single pulse contact (K BUTT)

Pedestrian button (PED BUTT)

Radio Receiver command

OFF - AUTOMATIC

Single pulse contact (K BUTT)

Pedestrian button (PED BUTT)

Radio Receiver command

DIP 7 ON - low speed in approaching ENABLED

OFF - low speed in approaching DISABLED

DIP 8 ON - electric lock command ENABLED

OFF - electric lock command DISABLED

DIP 9 ON - Hammering on complete close position to ease Manual

Release

- Hammering before opening to ease electric lock

unlocking

OFF - no impulse

DIP 10 ON - Extra thrust when reached closing position to make sure

that the mechanical bolt is fixed into the ground

OFF no impulse

DIP 11 ON - black out function ENABLED (See chart 2)

OFF - black out function DISABLED

DIP 12 Available for future applications

DIP 13 ON - safety strip self-test ENABLED

OFF - safety strip self-test DISABLED

DIP

14

to select type of motor (see chart 1)

DIP 15 to select type of motor (see chart 1)

DIP 16 to select type of motor (see chart 1)

JP 17 OPEN JUMPER 1 motor (M1) - 1 leaf

CLOSE JUMPER 2 motors (M1 and M2) - 2 leaves

JP1 => Pay attention that the jumper is inserted!

JP2 => Pay attention that the jumper is inserted!

JP3 => Pay attention that the jumper is inserted!

TORQUE TR1 Electronic regulator for motor torque

Adjustment of motor torque is carried out using the TORQUE Trimmer

which varies the output voltage to the head/s of the motor/s (turn

clockwise to increase torque).

This torque control is activated after 2 seconds form any manoeuvre

begging, whereas the motor is turned on at full power to guarantee the

starting at the manoeuvre begging.

P

A

Y

A

TTENTION: IF THE TORQUE TRIMMER SETTING IS

CHANGED, IT IS PREFERABLE T

O REPEAT THE

TIME PROGRAMMING.

LOW SPEED TR2 Electronic regulator for low speed on approach

WARNING: THE LOW SPEED FEATURES IS NOT AVAILABLE FOR

THE HYDRAULIC MOTORS (SEE CHART 1 POINTS 4-

5-8).

Adjustment of low speed is carried out using the LOW SPEED Trimmer

which varies the output voltage to the head/s of the motor/s (turn

clockwise to increase speed). Adjustment is carried out to establish the

correct speed at the completion of opening and closing, depending on

the structure of the gate, or if there is any light friction that could

compromise the correct working of the system. The low speed is

activated (DIP7 OFF) when the gate leaf is 0.50-0.60 meters away from

the complete close or open position.

LED WARNING

DL1 - programming activated (red)

DL2 - radio code programming (green) (only for CRX)

DL3 - gate opening M2 (green)

DL4 - gate closing M2 (red)

DL5 - gate opening M1 (green)

DL6 - gate closing M1 (red)

DL7 - photocell contact (NC) (red)

DL8 - safety strip contact (NC) (red)

FUSES

F1 T100mA Accessories protection fuse

F2 5A Motor protection fuse

POINT C - MOTOR ROT

A

TION DIRECTION CHECK

1 - Unlock the operators with the Manual Release, swing open the

leaves about halfway, lock the operators.

2 - Turn DIP1 to ON position, LED DL1 starts blinking.

3 - Press the PROG button and hold it (movement is now performed

in “man present” mode, open-stop-close-open-etc.).

When RED LEDS DL4 and DL6 are on, the gate leaves are closing

(with a phase shift of 4 seconds).

When GREEN LEDS DL3 and DL5 are on, the gate leaves are

opening (with a phase shift of 2 seconds).

Should any of the leaf open instead of closing, release PROG

button, turn off the main power and reverse the two phase wires

(V1/2 and W1/2) of the relevant motor.

4 - Press the PROG button and hold it to CLOSE completely the

gate, check leaves swinging and the closing mechanical stopper

position.

5 - Press the PROG button and hold it to OPEN completely the gate,

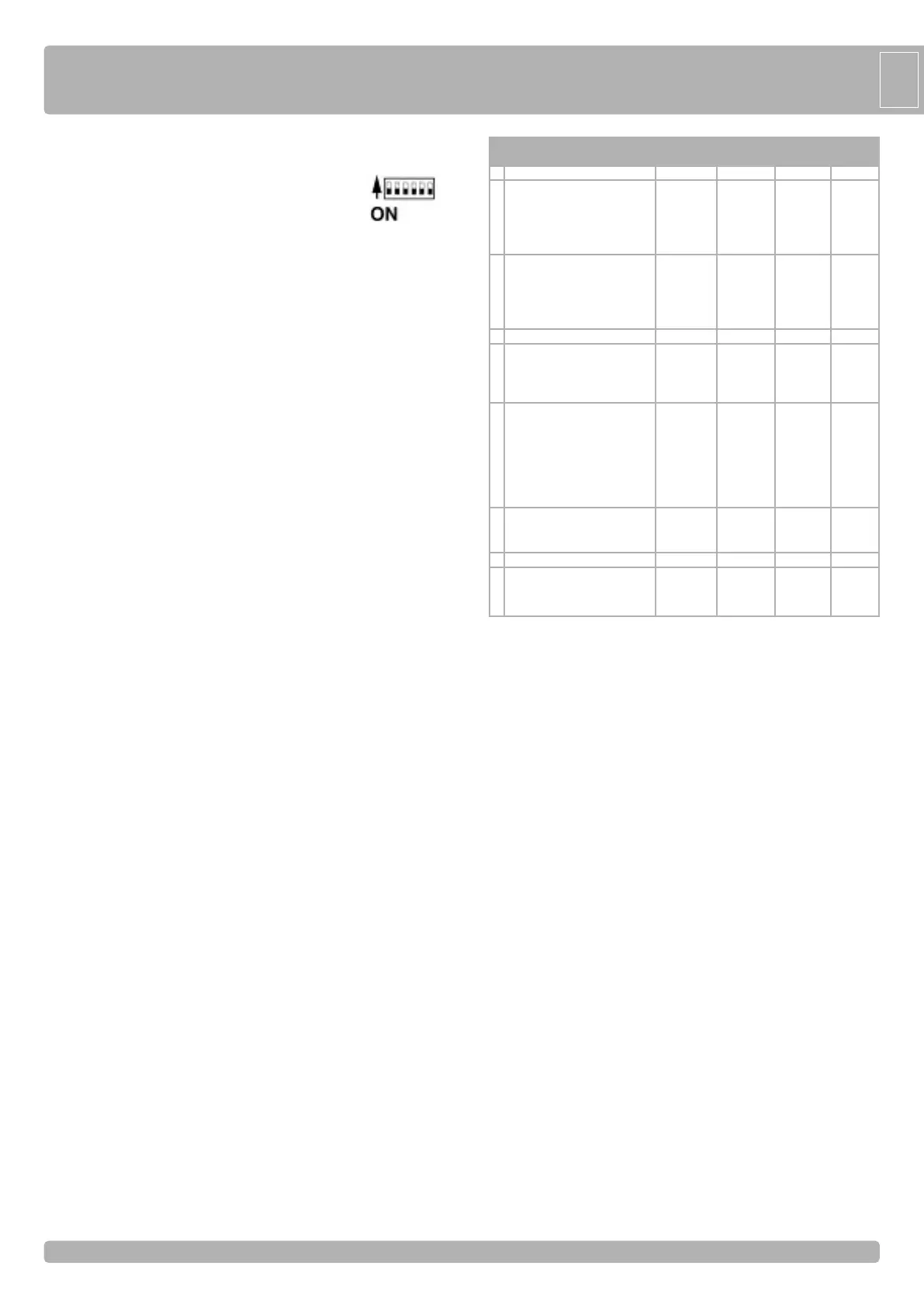

TABLE 1

TYPE OF MOTOR CODE DIP 14 DIP 15 DIP 16

1

KING 230/50 AA14001 OFF OFF OFF

K

ING L 230/50 AA14010

K

ING 220/60 AA14002

K

ING L 220/60 AA14011

K

ING ICE 230/50 AA14019

2 MAGIC IRR. 105° AA10960 ON OFF OFF

MAGIC IRR. 180° AA10965

MAGIC REV. 105° AA10920

MAGIC REV. 180° AA10930

PRATIC AA18001

3 PRINCE REV AA14045 OFF ON OFF

4 IDRO 27/1B AA10863 ON ON OFF

IDRO 27/R AA10860

IDRO 27 SUPER/R AA10867

IDRO 27 SUPER/1B AA10879

5 FLUID R DVI AA10899 OFF OFF ON

FLUID R SVI AA10901

FLUID 2B DVI AA10897

FLUID 2B SVI AA10898

IDRO 39/R AA10871

I

DRO 39/1B AA10876

I

DRO 39/2B AA10881

6

KING FAST 230/50 AA14008 ON OFF ON

KING 120/60 AA14003

KING L 120/60 AA14012

7 PRINCE WITH BRAKE AA14040 OFF ON ON

8 IDRO C 27/1B AA10884 ON ON ON

IDRO C 27/2B AA10882

IDRO C 27/R AA10883

Loading...

Loading...