23

COMMISSIONING

Adjusting the parameters on that screen, the reset curve below

will modify shape and slope to meet the needs of the specic ap-

plication.

20

CH SETPOINT (°C/ )°F

OUTDOOR TEMP. (°C/ )°F

Reset Curve

Design Boiler

93

Reset Curve Outdoor Design

1)Reset Curve Outdoor Mild Weather

2) Warm Weather Shutdown

Reset Cuve

Boiler Mild

Weather

Reset Curve Boiler Maximum

200

82 180

71 160

60 140

12049

10038

27 80

60

16

°C °F

-6

40

4

60

16

80

27

100

38

°F

°C

Reset Curve Boiler Minimum

Fig. 40

Reset Curve

− The boiler will re only when there is a call for heat and the

heating temperature setting is higher than the actual sup-

ply temperature. Hold buttons “+” or “-“ on the Cascade

screen (Fig. 47) to select the desired heating temperature. If

the external temperature sensor is connected (see Section

“2.13.3 Outdoor Temperature Sensor” pag. 16), check that

the calculated temperature is higher than the actual boil-

er temperature and that the outdoor temperature is lower

than “warm weather shut down” temperature.

− The boiler CH setpoint can be controlled by an analog input

signal provided by a remote means such as a Building Man-

agement System or a system controller. The analog input

0-10 VDC, is used to adjust the boiler setpoint between the

CH_Setpoint_Min and the CH_Setpoint_Max settings (Figure

35). To enable this operation mode, the parameter CH mode

must be set to 4 (see Array Control System Manual for ac-

cessing the parameter list).

CH Setpoint

Maximum

CH Setpoint

Minimum

1.51.02.0 10

Voltage

OFFON

ON/OFF

Hysterese

Fig. 41

10VDC Control mode

The CH setpoint Min and CH setpoint Max parameters can be ad-

justed to provide the desired temperature adjustment band. A

heat request will be generated by an input of 1.5 volts or higher.

The setpoint modulation will occur between 2 and 9 volts. The re-

quest for heat will be removed when the voltage drops below 1

volt.

All other safety and control functions associated with the boiler

will react normally to adverse condition and override control of the

analog signal to prevent an upset condition.

3.5.1 Minimum Water Flow (Heat Exchanger

Protection)

This unit is self-protected against low water ow. A ow meter

continuously monitors the water ow to each module. If the water

ow decreases below the minimum stated, the burner automat-

ically shuts off.

3.5.2 Heating System Pressure Test

If the pressure inside the heating circuit falls below the minimum

pressure for the system (7.5 PSI), the appliance switches off and

the 905PB inner display shows “Low water pressure” to indicate

that it is necessary to restore the correct pressure.

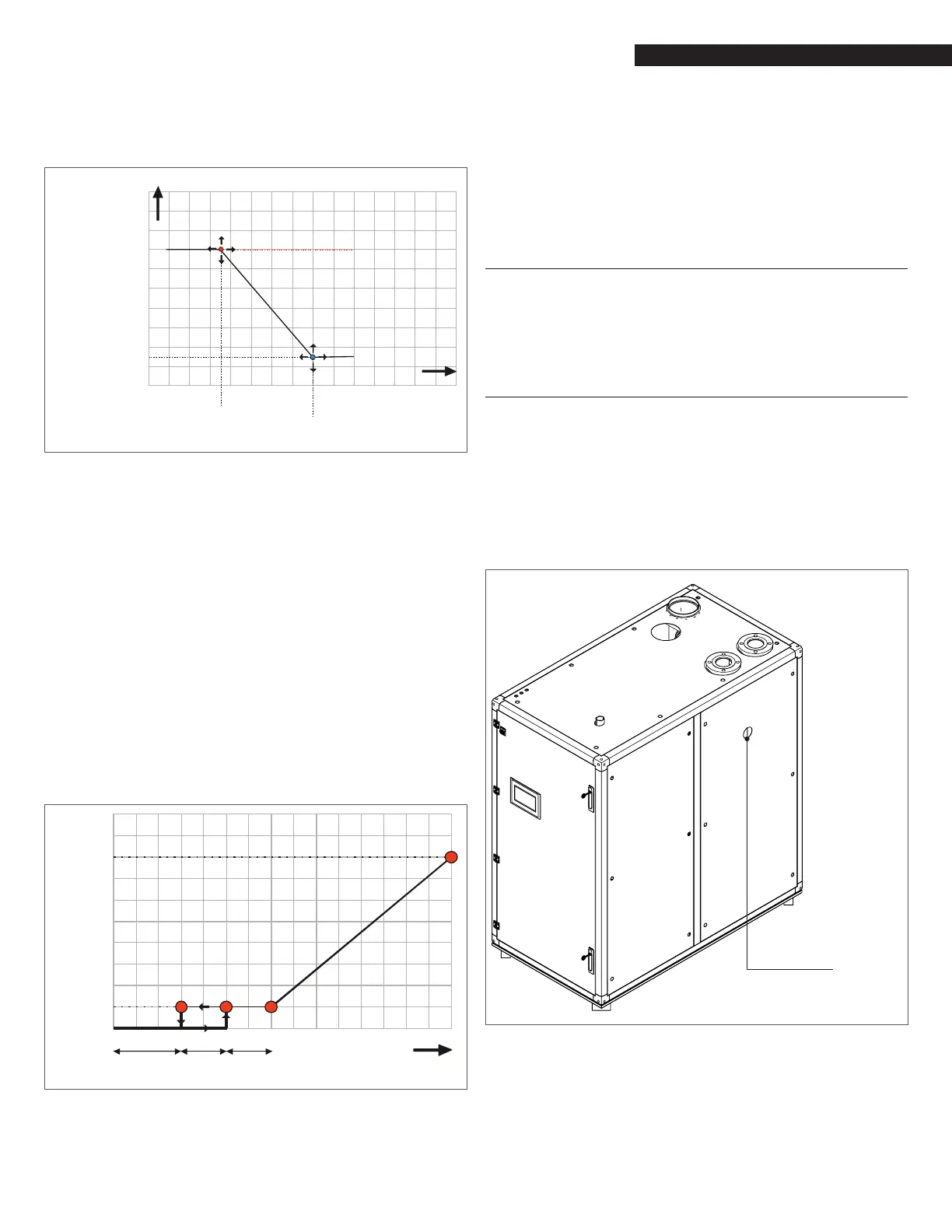

Open the lling valve and check the pressure on the temperature/

pressure gauge of Fig. 42.

The error will disappear when the pressure is back at the right

value. To prevent accidental relief valve openings, ll the heating

circuit slowly.

Gauge

Fig. 42

Temperature/Pressure Gauge location

Loading...

Loading...