68

RECYCLING AND DISPOSAL

68

APPENDIX

APPENDIX

VENTING MATERIAL

Array boilers must be vented and supplied with combustion and

ventilation air as described in this section.

Installation must comply with local requirements and with the

National Fuel Gas Code ANSI Z223.1. Array boilers vent and intake

air piping can be installed through the roof or through a sidewall.

Any of the vent/air piping methods covered in this manual can be

used. Do not attempt to install the boilers using any other means.

Suitable, UL approved, positive pressure, watertight vent materials

MUST be used for safety and UL certication.

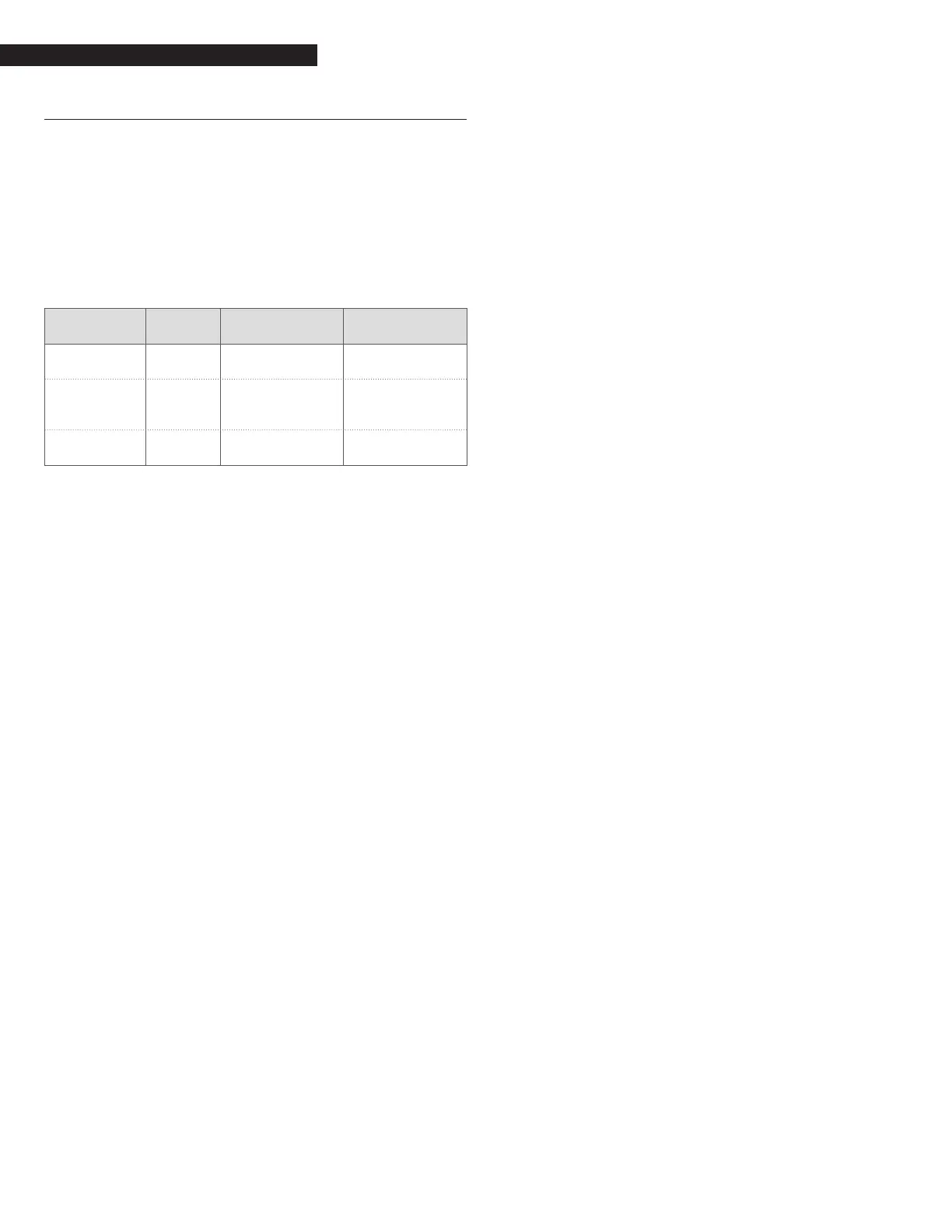

Array boiler can use the following material for venting:

Material Standard

Maximum Flue

Temperature (°F)

Approved Man-

ufacturers

CPVC Schedule

40, 80

ANSI/ASTM

F441

194

Polypropylene ULC S636 230

Centrotherm Eco

Systems (InnoFlue

SW)

AL29-4C

stainless steel

UL 1738

300+, limited only

by rating of seals

For specic venting components (terminals, ttings), contact the

respective vent manufacturer.

9

DANGER: It is extremely important to follow these venting in-

structions carefully. Failure to do so can cause severe personal

injury, death or substantial property damage.

7

9

DANGER: Use of cellular core PVC (ASTM F891), cellular core CPVC

or Radel® (polyphenosulfone) in venting systems is prohibited.

9

WARNING: Do not connect this gas appliance with any other

appliance unless approved by manufacturer. Failure to comply

with this WARNING could result in the accumulation of carbon

monoxide gas which can cause severe personal injury or death.

9

DANGER: The condensate traps must be lled with water or

combustion gases will enter the room with a risk of an exces-

sive level of carbon monoxide.

7

− Vent connectors serving appliances vented by natural draft

shall not be connected to any portion of mechanical draft

systems operating under positive pressure.

− Ensure the ue pipes and seals are not damaged.

− Use only primer and glue compounds approved for use

with the vent material used.

− Never install a barometric or a thermally controlled vent

damper with this boiler.

− Do not route the ue system piping through or inside an-

other duct that is used for exhausting air or other ue gas-

es.

− The condensate traps must be primed at all times. Failure

to do so may allow combustion gases to escape into the

boiler room.

− The unit is to be used for either direct vent installation or for

installation using room air for combustion. When room air

is used, it is necessary to provide an adequate opening for

the fresh make-up air intake.

− You must use any of the vent/air piping methods shown in

this manual.

− Be sure to locate the unit such that the vent and combus-

tion air piping can be routed through the building and

properly terminated.

− The boiler / vent installation must be in accordance with

Venting of Appliances, of the latest edition of the National

Fuel Gas Code, ANSI Z223.1/NFPA or applicable provisions of

the local, state and federal building codes.

− All vent pipes must be installed according to the vent man-

ufacturer’s instructions.

− The exhaust vent and the combustion air inlet lines must

be supported to prevent sagging per the vent manufactur-

er’s instructions.

− The boiler must not support the weight of any ductwork.

− Do not mix components from different systems. The vent

system could fail, causing leakage of ue products into the

living space. Use only approved materials.

− Use of cellular core PVC and CPVC for venting system is not

allowed.

− The vent system shall be installed so as to prevent the ac-

cumulation of condensate.

− Consult local and state codes pertaining to special building

code and re department requirements. Adhere to nation-

al code requirements.

− Observe the listed maximum lengths of vent system, which

are boiler model dependent.

− To avoid moisture and frost build-up and to maintain

clearances to openings on adjacent structures, 45° and 90°

elbows or tees may be attached to the end of the vent ter-

mination pipe to direct exhaust plumes away from the ad-

jacent structure. The total allowable vent length, maximum

number of elbows and distance of air intake restrictions

must be adhered to.

− Due to the high efciency of the unit it may discharge what

looks like white smoke especially when the outside air

temperature is cold. This is due to the presence of water

vapor, normally present in the exhaust gases.

Loading...

Loading...