61

RECYCLING AND DISPOSAL

61

APPENDIX

APPENDIX

APPENDIX G - VENTING SIZE DATA

While there is a positive ue pressure during operation, the combined pressure drop of vent and combustion air systems must not ex-

ceed the following equivalent length:

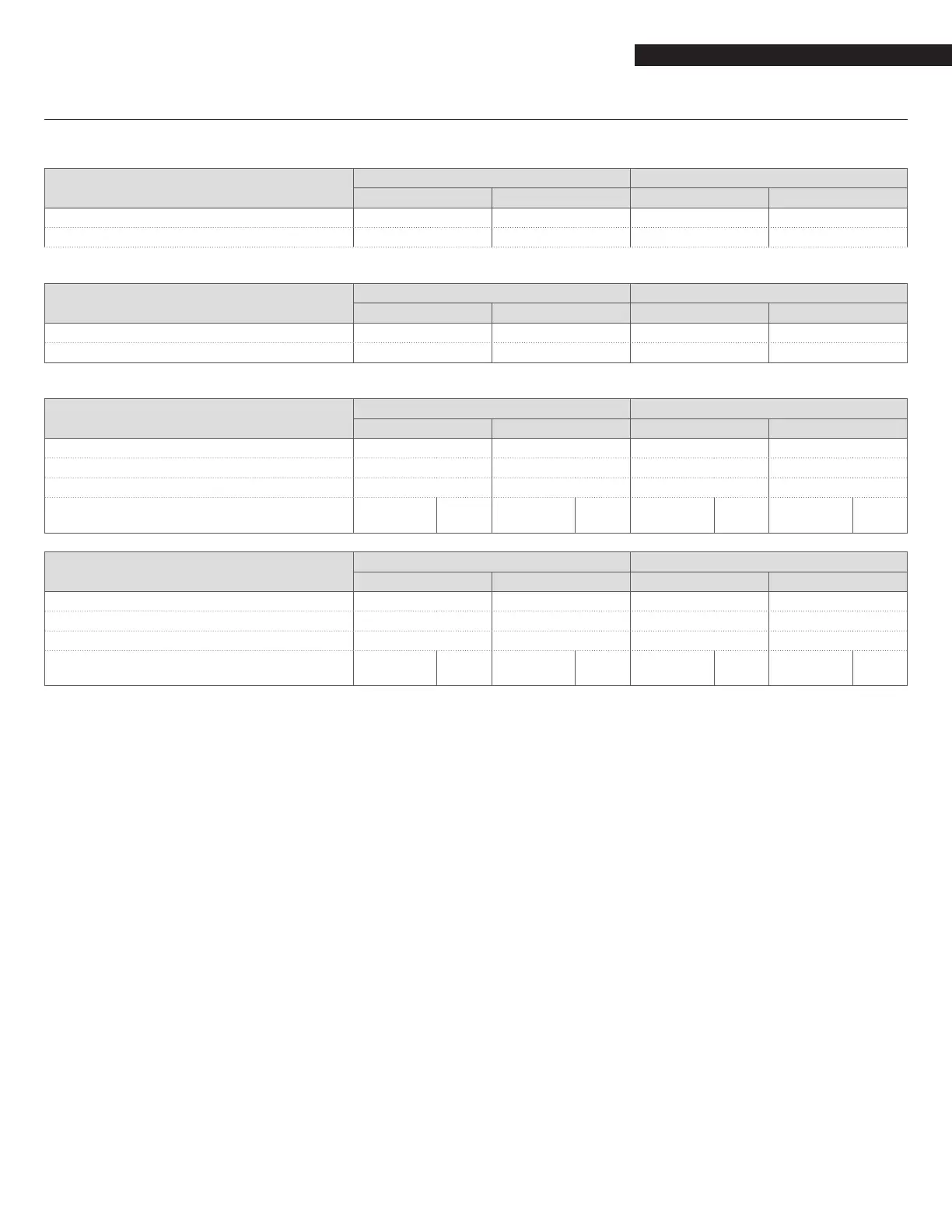

MODEL

PIPE SIZE - 4" PIPE SIZE – 5”

MAX equiv. mt MAX equiv. ft MAX equiv. mt MAX equiv. ft

ARRAY AR 399 SE 30 100 - -

ARRAY AR 500 SE 20 65 30 100

Fittings as well as pipe lengths must be calculated as part of the equivalent length, according to the following table:

MODEL

45° ELBOW - 4” 90° ELBOW - 5"

MAX equiv. mt MAX equiv. ft MAX equiv. mt MAX equiv. ft

ARRAY AR 399 SE 1,5 5 3,7 12

ARRAY AR 500 SE 1,5 5 3,7 12

Data for Venting size

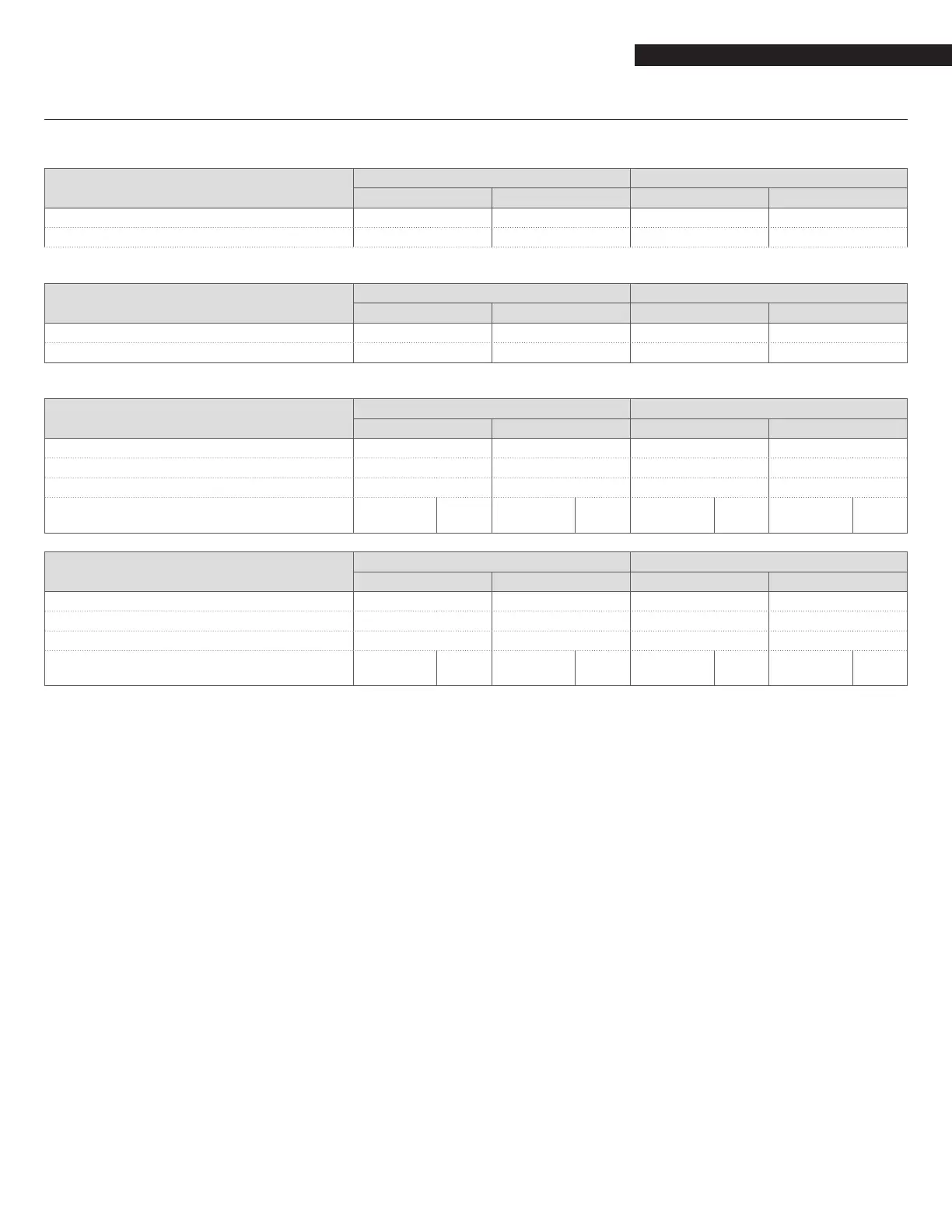

ARRAY AR 399 SE

T supply / return (F°) - 176 / 140 T supply / return (F°) - 104 / 86

Maximum Input Minimum Input Maximum Input Minimum Input

CO

2

9% 9% 9% 9%

Exhaust gas mass (weight) 6.56 lb/s 0.65 lb/s 6.56 lb/s 0.66 lb/s

Flue temperature 161.6 °F 143.6 °F 107.6 °F 89.6 °F

Max. pressure at boiler exit @ high re con-

dition

0,9 in H

20 220 Pa 0,1 in H20 20 Pa 0,9 in H20 230 Pa 0,1 in H20 25 Pa

ARRAY AR 500 SE

T supply / return (F°) - 176 / 140 T supply / return (F°) - 104 / 86

Maximum Input Minimum Input Maximum Input Minimum Input

CO

2

9,3% 9% 9,3% 9%

Exhaust gas mass (weight) 7.99 lb/s 0.82 lb/s 7.99 lb/s 0.82 lb/s

Flue temperature 161.6 °F 143.6 °F 107.6 °F 89.6 °F

Max. pressure at boiler exit @ high re con-

dition

0,8 in H

20 200 Pa 0,1 in H20 20 Pa 0,9 in H20 220 0,1 in H20 20 Pa

Cascade Venting of Multiple Boiler Installations

When multiple boilers of the same model size are installed within a common room it is permissible to cascade the venting connecting all

boilers to a single exhaust system. No more than eight (8) boilers should be cascade vented together.

The boiler/ vent installation must be in compliance with ANSI Z223.1/ NFPA 54 and all local, state, and federal regulations for building code.

Venting system shall be designed to maintain suitable vent pressure at the boiler exhaust collar.

For a list of suitable venting materials consult the installation manual section: “Venting material” page 68

Adapters are available for various brands of venting materials. Consult the factory for a list of available adapters.

Venting components from different manufacturers shall not be mixed.

Adequate combustion air must be supplied to the boiler to ensure safe operation. A properly sized direct connected common combustion

air duct may be used for sealed combustion air to the boiler cascade.

For additional information regarding combustion air supply consult the installation manual section: “Combustion Air” page 69

Prior to installing a permanent vent system refer to the Installation Manual, ANSI Z223.1/ NFPA 54, and all local, state, and federal regula-

tions for building code to ensure compliance with the requirements of these articles.

Loading...

Loading...