3055

8

Technical description of the burner

4.1 Technical data

Tab. A

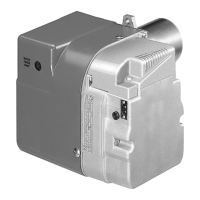

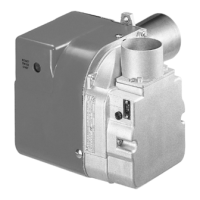

4.2 Burner description

1 Pump

2 Control box

3 Reset button with lock-out lamp

4 Flange with insulating gasket

5 Air damper adjustment screw

6 Snorkel (BF)

7 Pump pressure adjustment screw

8 Pressure gauge port

9 Photoresistance

4.3 Burner equipment

Flange with insulating gasket .............................................. No. 1

Screws for flange to be fixed to boiler ................................. No. 4

Screw and nuts for flange ................................................... No. 1

Hoses with nipples .............................................................. No. 1

Screw of by-pass pump....................................................... No. 1

Plastic air cover................................................................... No. 1

4 pin plug............................................................................. No. 1

Hexagonal key .................................................................... No. 1

4 Technical description of the burner

Type 744T3K 744T5K

Output - Thermal power

(with air at 20 °C)

1.8 - 3.5 kg/h

21.3 - 42 kW

2.8 - 4.5 kg/h

33.5 - 54 kW

Fuel

Kerosene, viscosity 1.6 – 6 mm

2

/s at 20 °C (Hi = 11.97 kWh/kg)

Electrical supply Single phase, ~ 50Hz 230 V ± 30%

Motor Run current 0.85 A – 2700 rpm – 283 rad/s

Capacitor 4.5 F

Ignition transformer Secondary 8 kV – 25 mA

Pump Kerosene, maximum pressure 10 bar (145 psi)

Absorbed electrical power 0.16 kW

The hoses supplied with this burner set for

Kerosene use are not suitable for use with Gas oil

containing a Bio blend.

Please refer to the spare part list for the specific

hoses suitable for bio fuel use.

In case of use with gas oil containing up to 30%

Bio blend, it will be essential to use flexible oil

lines suitable for bio fuel use.

Please contact Riello for further information.

Loading...

Loading...