Do you have a question about the Riello RDB2.2 15-21 and is the answer not in the manual?

Manual's role, importance for consultation and accompanying the burner.

Explains danger symbols (DANGER, WARNING, CAUTION) and their severity levels.

Manufacturer's warranty terms, user responsibilities, and liability exclusions.

Advice on using bio fuel blends up to 30%, covering storage, filtration, and components.

Burner design compliance, potential dangers from misuse, and basic precautions.

Essential rules for safe operation, including prohibitions on unauthorized access and cleaning.

User's duty to ensure personnel are trained, aware of safety, and report issues.

Details technical data like output, fuel type, electrical supply, motor, and pump specs.

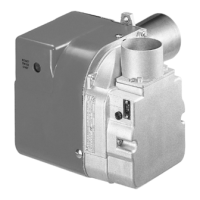

Identifies parts, provides dimensional drawings, and explains firing rate diagrams.

Lists included parts like flange, screws, hoses, and tools provided with the burner.

Safety notes for installation area, electrical disconnection, and proper burner handling.

Checks for consignment integrity, burner label details, and disposal of packaging.

Guidance for installers on using gas oil with bio fuel blends, including tank and hose compatibility.

Approved burner working positions and instructions for boiler fixing and burner assembly.

Details the pump's function, one/two pipe systems, and warnings related to fuel types.

Explains pressurised and vacuum one-pipe systems, including priming and filter recommendations.

Describes vacuum two-pipe systems, return line requirements, and priming procedures.

Critical safety instructions for electrical wiring, including disconnection and qualified personnel.

Illustrates the electrical connections for the control box, motor, and sensors.

Emphasizes qualified personnel for first start-up and checks of safety devices.

Guidance on adjusting CO2 levels based on outside air temperature for optimal combustion.

Recommends specific nozzles and replacement frequency for emission compliance.

Procedures for setting pump pressure and adjusting air dampers for performance tuning.

Details electrode positioning and explains normal and lock-out burner start-up sequences.

Highlights safety during maintenance and the recommended annual check schedule.

Procedures for inspecting and cleaning combustion head, burner, fan, photoresistance, electrodes, and filters.

Guidance on inspecting hoses, checking fuel tanks for contamination, and boiler maintenance.

Lists common faults, their causes, and recommended solutions for burner operation.

| Model | RDB2.2 15-21 |

|---|---|

| Type | Burner |

| Output Range | 15-21 kW |

| Ignition Type | Electronic |

| Nozzle Pressure | 10 bar |

| Electrical Supply | 230 V / 50 Hz |