32 RITTAL cooling unit assembly and operating instructions

7 Inspection and maintenance

EN

6.2.9 Resetting the Comfort controller

After the occurrence of faults A03, A06 and A07,

you will need to reset the Comfort controller.

• Press buttons 1 (

▲

)

and 3 (

▼

) (Fig. 38) simul-

taneously for 5 sec.

The system messages will disappear and the tem-

perature display will be shown.

7 Inspection and maintenance

7.1 General

The cooling circuit is designed in the form of a main-

tenance-free, hermetically sealed system. The cool-

ing unit is filled with the required quantity of refriger-

ant at the factory, checked for leaks, and subjected

to a functional test run.

The installed maintenance-free fans are mounted on

ball bearings, protected against moisture and dust,

and fitted with a temperature monitor. The life expec-

tancy is at least 30,000 operating hours. The cooling

unit is thus largely maintenance-free. All that may be

required from time to time is to clean the components

of the external air circuit using a vacuum cleaner or

compressed air if they become visibly dirty. Any

stubborn, oily stains may be removed using a non-

flammable detergent, such as degreaser.

Maintenance interval: 2000 operating hours. Depen-

ding on the level of contamination in the ambient air,

the maintenance interval may be reduced to suit the

air pollution intensity.

Sequence of maintenance measures:

– Check the level of dirt.

– Filter soiling? Replace the filter if necessary.

– Cooling membranes soiled? Clean if necessary.

– Activate test mode; cooling function OK?

– Check noise generation of compressor and fans.

7.1.1 Compressed air cleaning

SK 3304.xxx, SK 3305.xxx

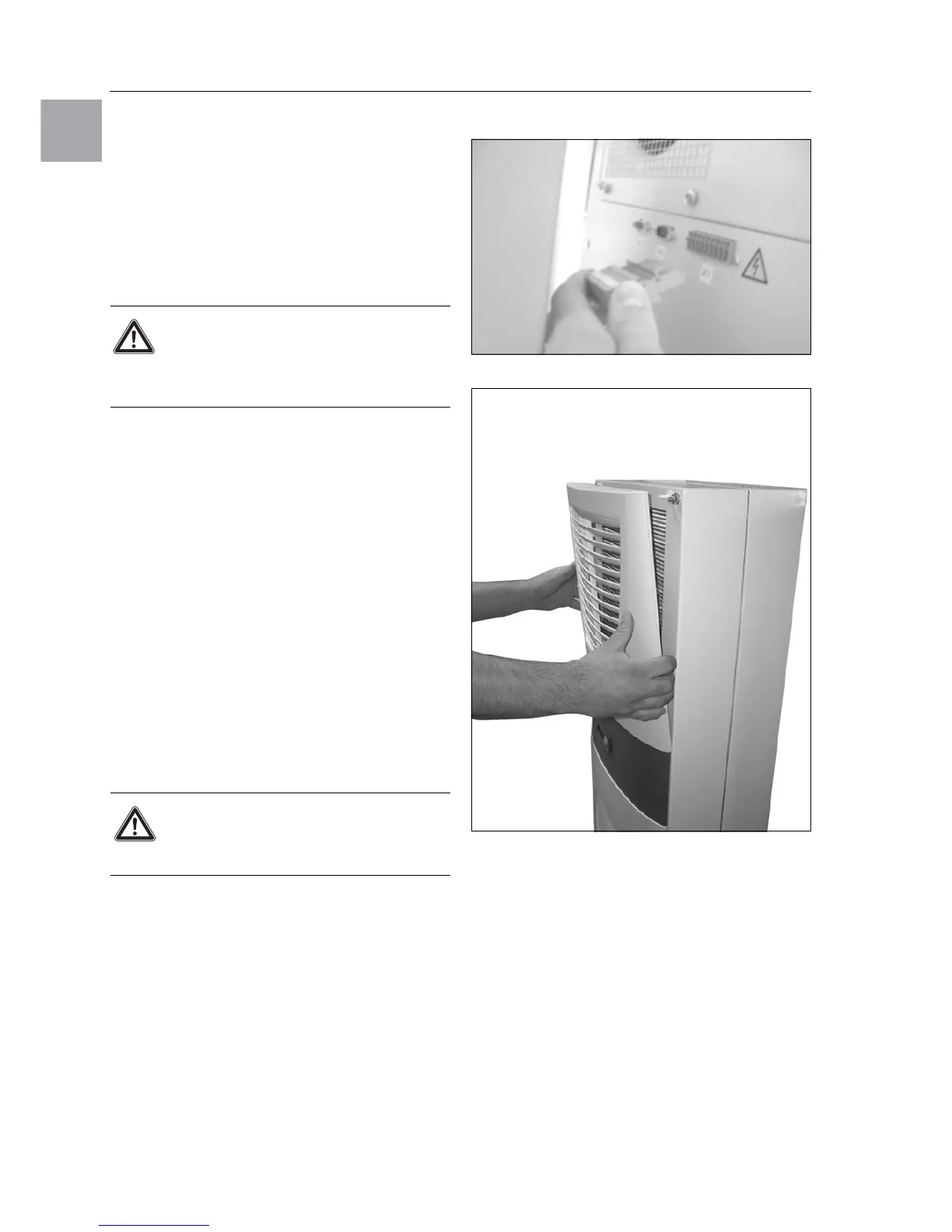

Fig. 41: Disconnect the power cord

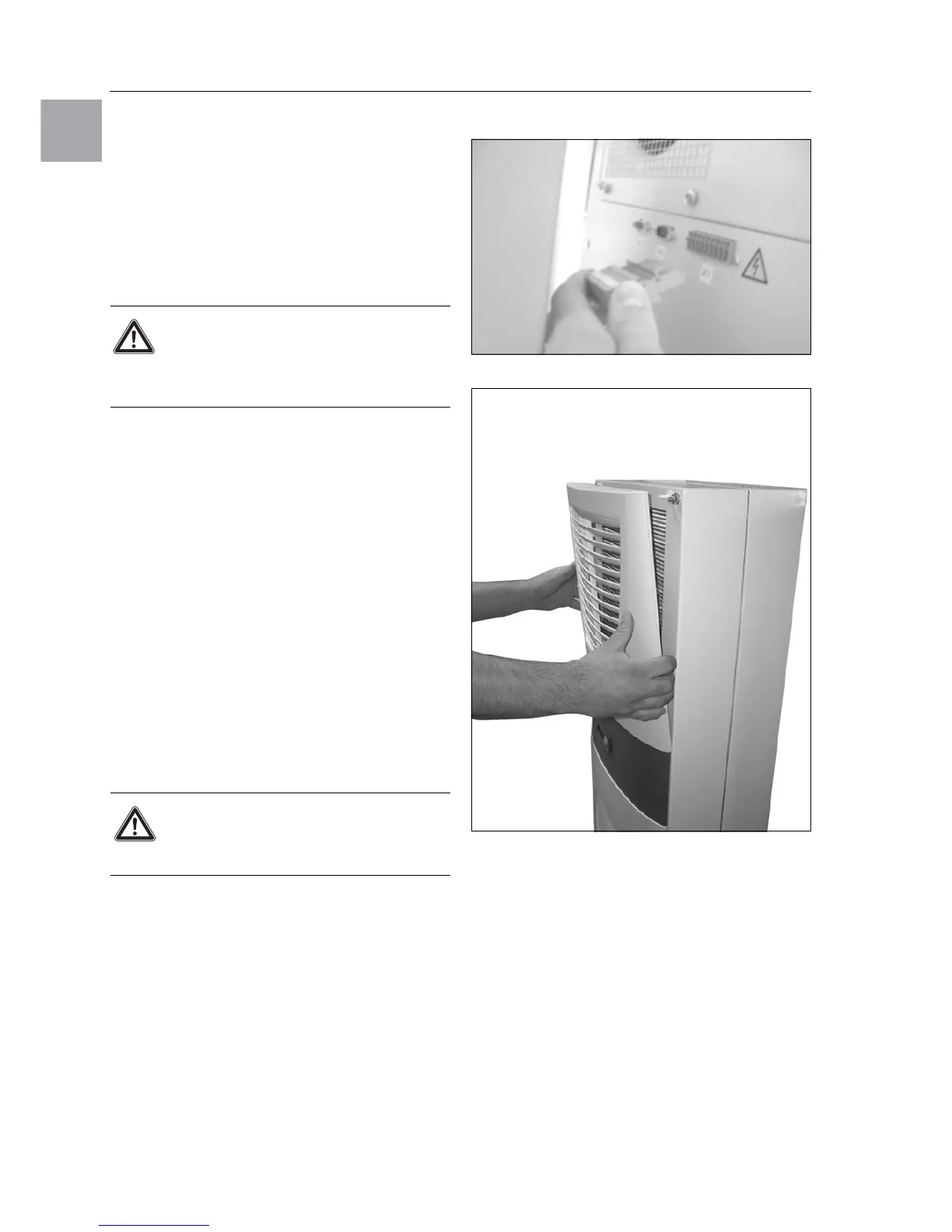

Fig. 42: Remove the upper louvred grille

Risk of electric shock!

The unit is live.

Switch off the power supply before open-

ing, and take suitable precautions

against

it being accidentally switched back on.

Caution!

Risk of fire!

Never use flammabel liquids

for cleaning.

Loading...

Loading...