RCMR Pag. 41 Rev. 02 02 13

UK

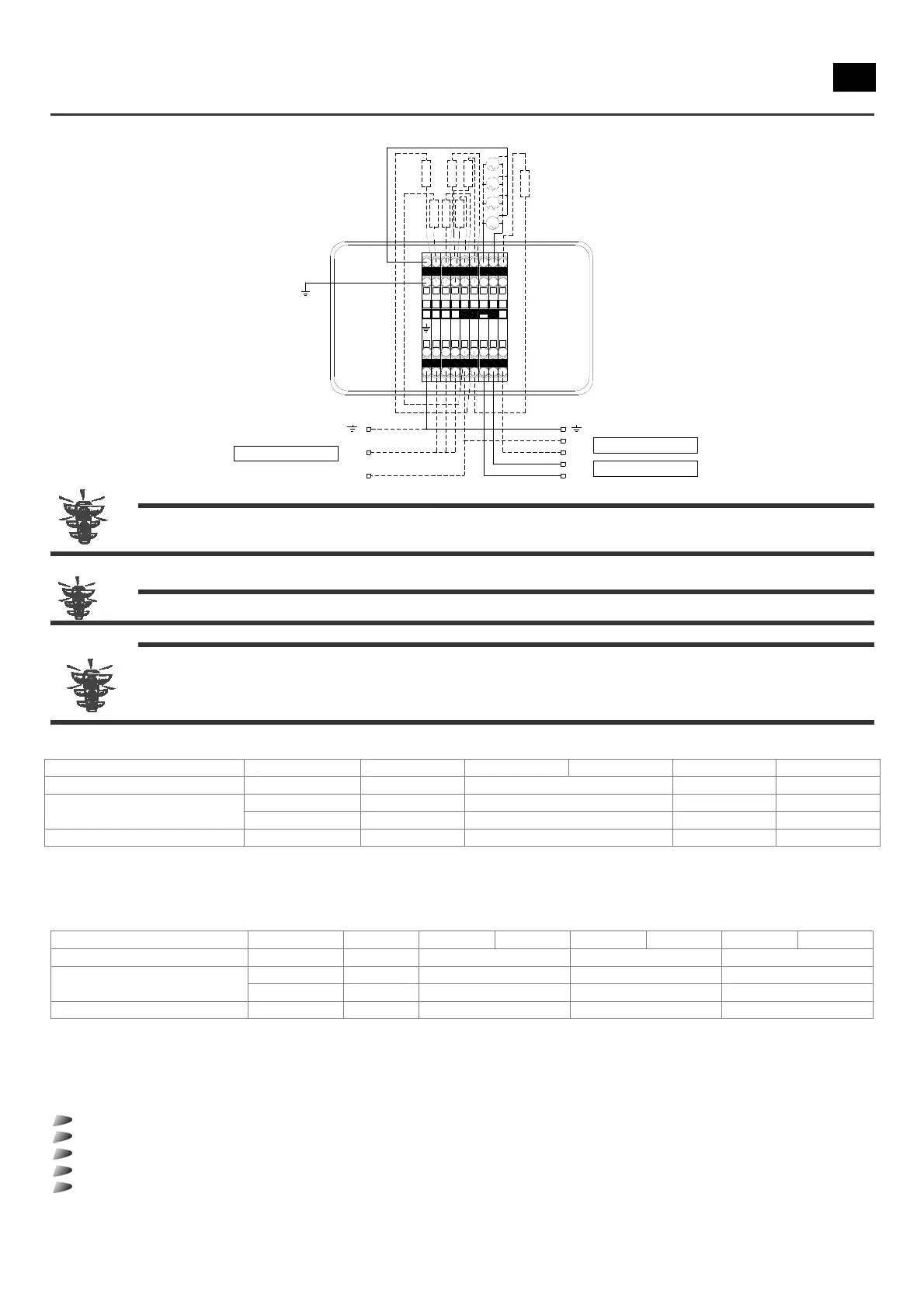

Figure 13 – Wiring diagram RCMR Ø450 with defrosting heaters powered with 230V/1Ph/50-60Hz.

M2

M4

M3

M1

123NN4N

5

1

R

3

R

5

R

7

R

2

R

4

R

6

R

L

N

L

N

230V/1Ph/50-60Hz

230V/1Ph/50-60Hz

L

230V/1Ph/50-60Hz

N

ATTENTION: the defrost heaters are only included in the ED version (version with electrical defrost Figure 12-13 see R1,

R2 ,R3, R4, R5 and R6).The drainage heater is supplied as optional (Figure 12- 13 see R7)

To make the wires pass, use the side openings that are already arranged.

ATTENTION

:

Rigorously follow the wiring diagrams reported above to avoid damages.

ATTENTION: Rigorously follow the wiring diagrams reported above to avoid damages to the motor. The motors

themselves are equipped with a protective, automatic restart system. If you intend to use a system to adjust

the number of fan motor revs, make sure that it is compatible with the fan motor; incompatible systems may

generate noise and cause damages.

Technical data of the RCMR Ø350 motors and heaters

The different RC models are grouped in the charts below:

Model RCMR 13506__ 23504__ 23508__ 33506__ 43506__

Fan motors No. x Ø (mm) 1x350 2x350 3x350 4x350

Fan motors

absorption (*)

A 0.58 1.16 1.74 2.32

W 130 260 390 520

Defrosting heater power (**) W 1800 2800 4096 5360

(*) Electrical power supply of the fan motors: 230/1/50 Hz

(**) only valid for the ED version. Electrical defrost arranged for 400/3/50Hz.

Technical data of the RCMR Ø450 motors and heaters

The different RC models are grouped in the charts below:

Model RCMR 14508__ 24506__ 24508__ 34506__ 34506__ 44506__ 44508__

Fan motors N°x Ø (mm) 1x450 2x450 3x450 4x450

Fan motors

absorption (*)

A 2.36 4.72 7.08 9.44

W 490 980 1470 1960

Defrosting heater power (**) W 3960 6600 8700 9240

(*) Electrical power supply of the fan motors: 230/1/50 Hz

(**) only valid for the ED version. Electrical defrost arranged for 400/3/50Hz.

4.3.6 Inspections before start-up

Before starting the air-cooled evaporator, make sure that:

the blockage screws are tightened;

the electrical connections have been performed properly;

there are no refrigerant leaks;

the panels are tightened;

the spaces for maintenance are sufficient.

Loading...

Loading...