Rivulis F2400 Media Filter

3. FILLING THE MEDIA LAYERS

Prior to media filling verify that all conical diffusers set on the distribution plate are installed

and good state. (Do not use filter with missing or damaged diffusers!!!)

The filtration media will be filled only after leakage checking.

Close array’s inlet valve.

Fill the gravel media through the top port of the filter, according to recommended weights (see

Table 1).

NOTE: The conical diffusers set on the double bottom must be totally covered by the

gravel media.

After having filled in the media layer, close the filling port tightly.

NOTE: In order to receive efficient filtering results, (in case the media layer is not supplied by

Rivulis) care should be taken to verify that the media layer particles should have sharp edges,

its minimal grain size – 0.6 mm; maximal unity coefficient - 1.5.

Recommended media layer: crushed basalt 1-2 mm, or crushed granite 1-2 mm

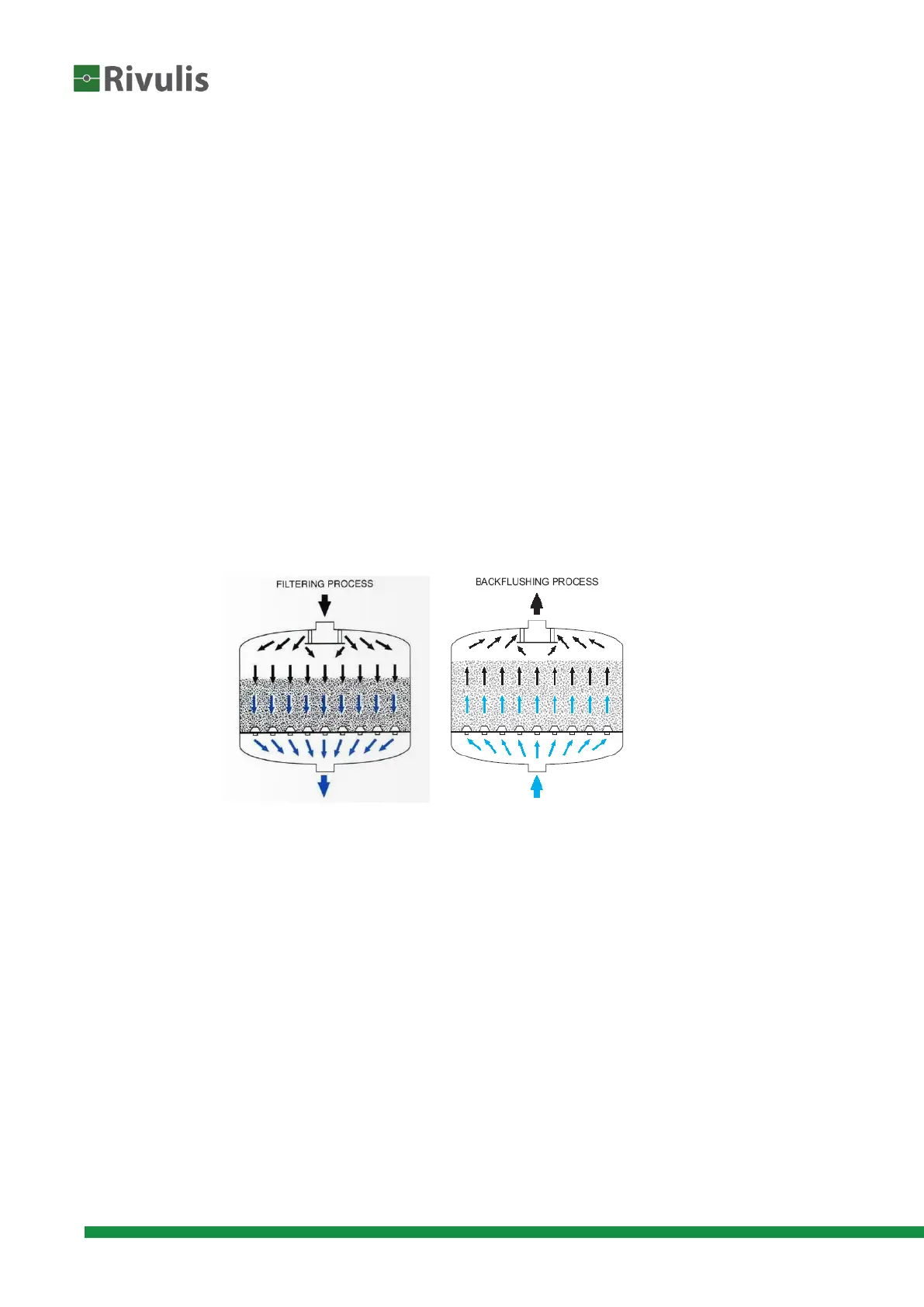

Image. 5. Flow direction of water through a media filter during filtration (left) and backwash

(right)

4. THE BACKWASH PROCESS

The backwash process is performed for each filter separately; one after the other

consecutively until each filter has been backwashed; this is called a Backwash Cycle. (In

arrays containing more than 10 filters the backwash is performed for two filters

simultaneously; one in every branch)

The backwash of a media filter is carried out by passing clean water (filtered by the other filter

units) in reverse flow, in an upward direction of the filter being backwashed. (see Images 5

and 7)

The reversal of water flow through the filter fluidizes the media, causing a turbulent expansion

of the media, which flushes out the entrapped debris through the filter's flushing valve and into

the Backwash Manifold. The flow limiting valve on the backwash manifold is used to regulate

the flushing to the required backwash flow rate.

Loading...

Loading...