!

!

Setting the manifold

Manifolds Manual 25

(*1) ATTENTION:

Whenrstputintooperation,theheatmustgraduallybebroughtintotheunderoorbecauseof

the linear expansion of the screed and the risk of cracking.

Advice:Useedgeisolationallaroundtocounterbalancethelinearexpansionoftheoorduring

warming up.

Robot manifolds are standard delivered in a hydraulically neutral design (in other words no

pressure difference between the supply and return primary.

When exchanging the pump, if required, account should be taken that only the socket head

screws will be unscrewed. Any form of guarantee will lapse if changes are made to the nickelplated

socketheadscrewsinthepumpinghouse(back-panel).

PLEASE NOTE: THE PUMP MUST ALWAYS BE RUNNING WHEN THE SYSTEM IS FILLED. This

will prevent damage to the pump, which will invalidate the guarantee.

Additives:

Theadditionofchemicals(waterdescalersordetergentsetc.)totheboilerwatercanadversely

affect the lifetime of the system or even damage it. An exception to this is mono-ethylene Glycol

(rateofmaximum30%Glycol).Thisadditiveisusediftheunderoorheatingismountedoutside

i.e. driveway heating.

Mounting actuators, optional:

Actuators can be used in combination with a room control. It will then be possible to control each

areaseparately.Removethehandwheelofthethermostaticvalve(whitecover)andmountthe

Robot actuator 24 or 230 Volt.

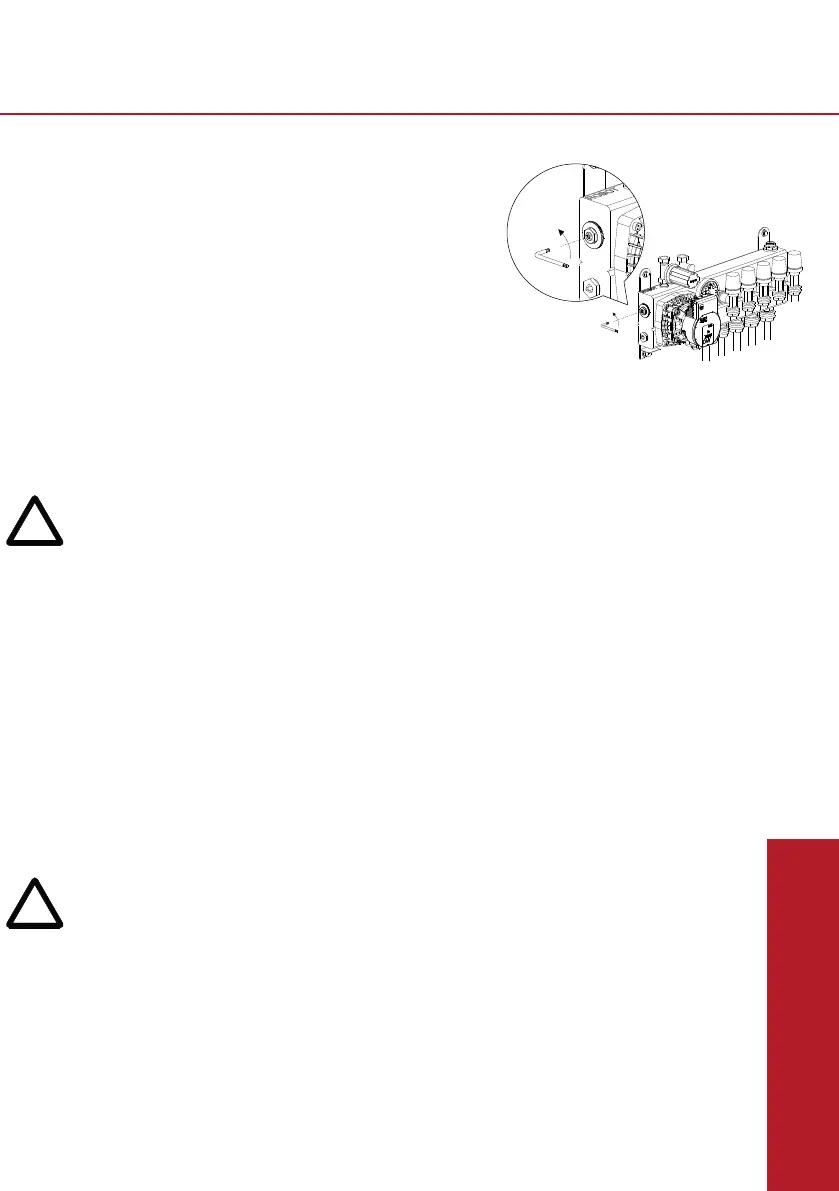

7.2 Setting of the PRO-valve on Standard and Optimum Flow manifolds

When fully closed (clockwise) there will be a minimum

mixtureofowand (underoor)returnwater.Thissetting

can be used for sourcetemperatures to about 40°C*

Whenfullyopen(counterclockwiseinfactorysetting)there

will be mixture of the ow and (underoor) returnwater.

This setting can be used for sourcetemperatures from

70°C.

The setting is done by means of an Allan-key. The more

you close the valve in this way, the less mixture there will

be, hence the lower the sourcetemperature can be.

*We recommend to leave the PRO valve a bit open to be sure of circulation. (One rotation is

enough)

Loading...

Loading...