------------

Rolls-Royce

&

Bentley-------

Air

Conditioning

System

Manuol

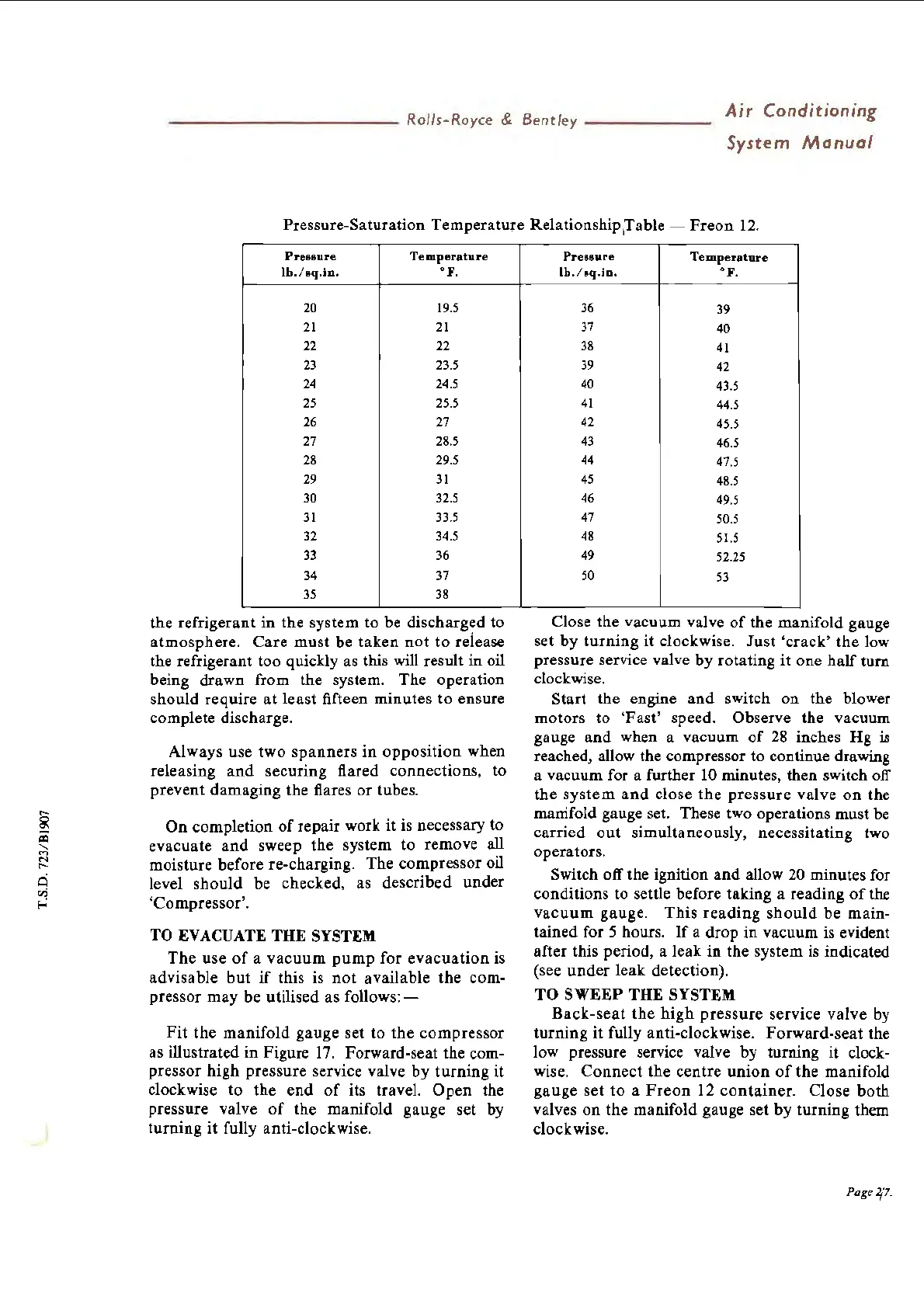

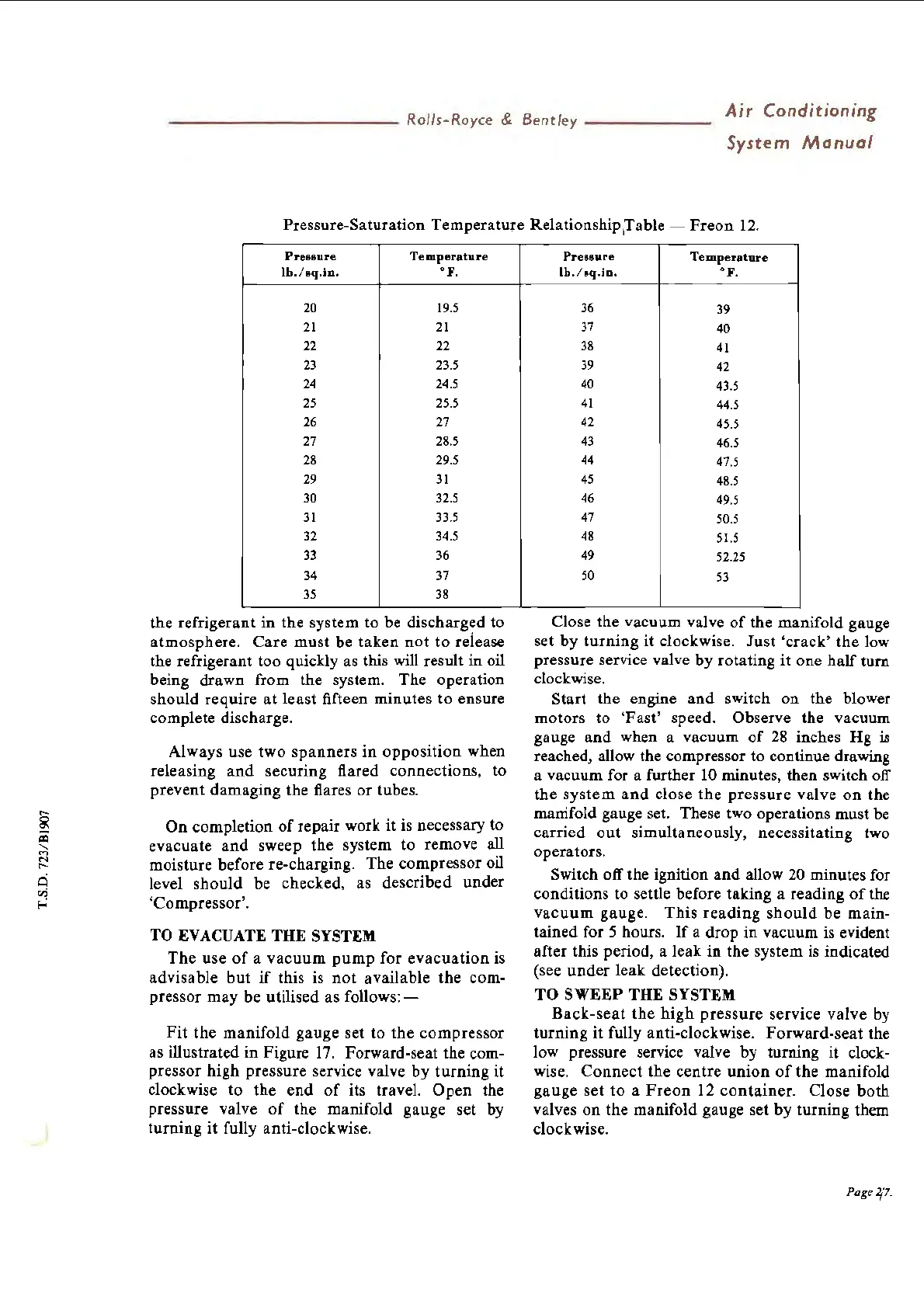

Pressure-Saturation

Temperature

Relationship

1

Table -

Freon

12.

Pressure

Temperature

lb./eq.h>..

•F.

20

19.5

21

21

22

22

23

23.5

24

24.5

25

25.5

26 27

27

28.5

28

29.5

29

31

30

32.5

JI

33.5

32

34.5

33

36

34 37

35 38

the refrigerant

in

the system to be discharged to

atmosphere.

Care

must

be

taken

not

to

reiease

the refrigerant too quickly as this will result in oil

being drawn from the system.

The

operation

should

require

at

least

fifteen minutes

to

ensure

complete discharge.

Always use

two

spanners

in

opposition

when

releasing

and

securing flared connections, to

prevent damaging the flares

or

tubes.

On

completion

of

repair work it is necessary to

evacuate

and

sweep the system to remove all

moisture before re-charging. The compressor oil

level

should

be

checked, as described under

'Compressor'.

TO EVACUATE THE SYSTEM

The

use

of

a

vacuum

pump

for

evacuation

is

advisable

but

if

this is

not

available

the

com-

pressor may

be

utilised as

follows:-

Fit

the

manifold

gauge set to

the

compressor

as illustrated in Figure

17.

Forward-seat the com-

pressor

high pressure service valve

by

turning

it

clockwise to the

end

of

its travel.

Open

the

pressure valve

of

the manifold gauge set by

turning

it

fully anti-clockwise.

Press11re

Temperature

lb.leq.io.

"F.

36

39

37

40

38

41

39

42

40

43.5

41

44.S

42

45.5

43

46.S

44

47.5

45

48.5

46

49.5

47

50.5

48

51.S

49

52.25

50

53

Close the vacuum valve

of

the manifold gauge

set

by

turning

it clockwise.

Just

'crack'

the

low

pressure service valve

by

rotating it

one

half

tum

clockwise.

Start

the engine

and

switch

on

the blower

motors to

'Fast'

speed. Observe the vacuum

gauge

and

when a vacuum

of

28

inches Hg

is

reached, allow the compressor to continue drawing

a vacuum for a further 10 minutes, then switch off

the

system

and

close

the

pressure

valve

on

the

manifold gauge set. These two operations must

be

carried

out

simultaneously, necessitating two

operators.

Switch off the ignition

and

allow

20

minutes for

conditions to settle before taking a reading

of

the

vacuum

gauge.

This

reading

should

be

main-

tained for

5 hours.

If

a drop in vacuum is evident

after this period, a leak in the system is indicated

(see

under

leak detection).

TO

SWEEP

THE SYSTEM

Back-seat

the

high

pressure

service valve

by

turning

it fully anti-clockwise. Forward-seat the

low pressure service valve by turning it clock-

wise.

Connect

the

centre

union

of

the manifold

gauge

set

to

a

Freon

12

container.

Close

both

valves

on

the manifold gauge set by turning them

clockwise.

Page

ljl.

Loading...

Loading...