C/3

-----------

- -

Rolls-Royce

&

Bentley-------

Air

Conditioning

System

Manual

carbon ring.

In

some cases it may be bonded to the

retainer.

Remove the seal assembly from the shaft

by

prying

behind the drive ring which is

that

portion

of

the seal

assembly farthest back on the shaft. When prying

the seal assembly from the shaft, do not scratch the

crankshaft

or

the sealing housing face on the

crankcase.

All parts should

be

cleaned prior to re-assembly.

INSTALLATION

Check the front face

of

the crankshaft front bearing

journal

in

the seal housing, to make certain

that

the

two seal drive pins are in place. These two drive pins

are located l

B0°

apart

on the front bearing journal

face.

Wash all portions

of

the seal assembly in clean

refrigerant oil.

Push the seal assembly, less the carbon ring,

if

it

is

free, over the end

of

the shaft, with the carbon ring

retainer facing out. Move the assembly along the

shaft a

few

times to ensure a good seal between the

neoprene ring and the shaft. Push the seal assembly

all the

way

on the shaft making sure the slots in the

seal drive ring engage the drive pins on the shaft

bearing journal face.

If

the carbon ring is separate, place it in the ring

retainer

so

that

the polished surface is facing out.

The carbon ring must engage the driving lugs and be

fully seated in the ring retainer.

Place a very light film

of

clean refrigerant oil on

the matching metal foccs where the seal plate gasket

is

to be placed. Place the seal plate gasket, dry, in

position on the seal housing face.

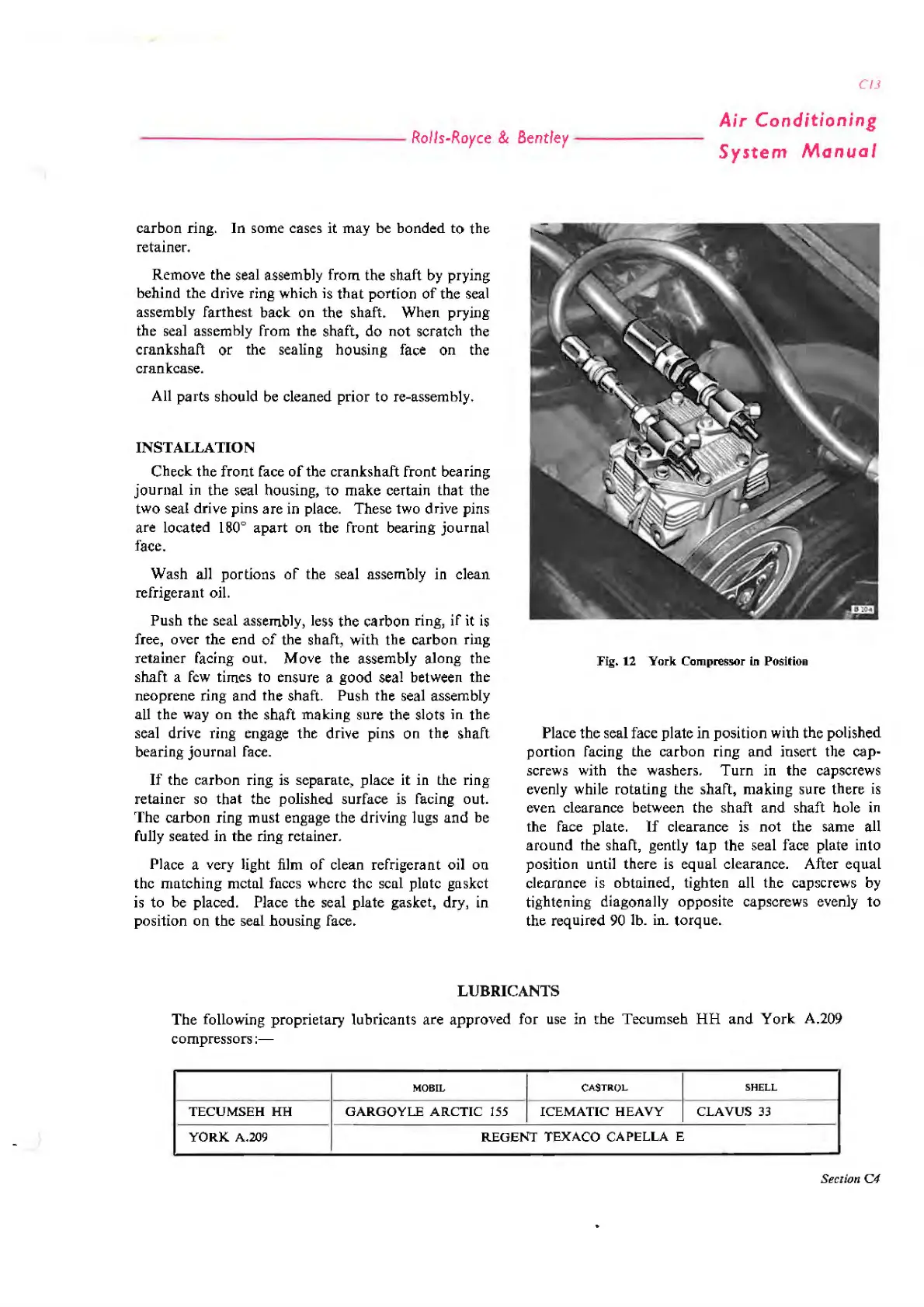

Fig. 12 York Compressor

in

Position

Place the seal face plate in position with the polished

portion facing the carbon ring and insert the cap-

screws with the washers.

Turn

in the capscrews

evenly while rotating the shaft, making sure there

is

even clearance between the shaft

and

shaft hole in

the face plate.

If

clearance is not the same all

around the shaft, gently tap the seal face plate into

position until there is equal clearance. After equal

cleo.ro.nce

is obtained, tighten all the capscrews

by

tightening diagonally opposite capscrews evenly to

the required

90

lb. in. torque.

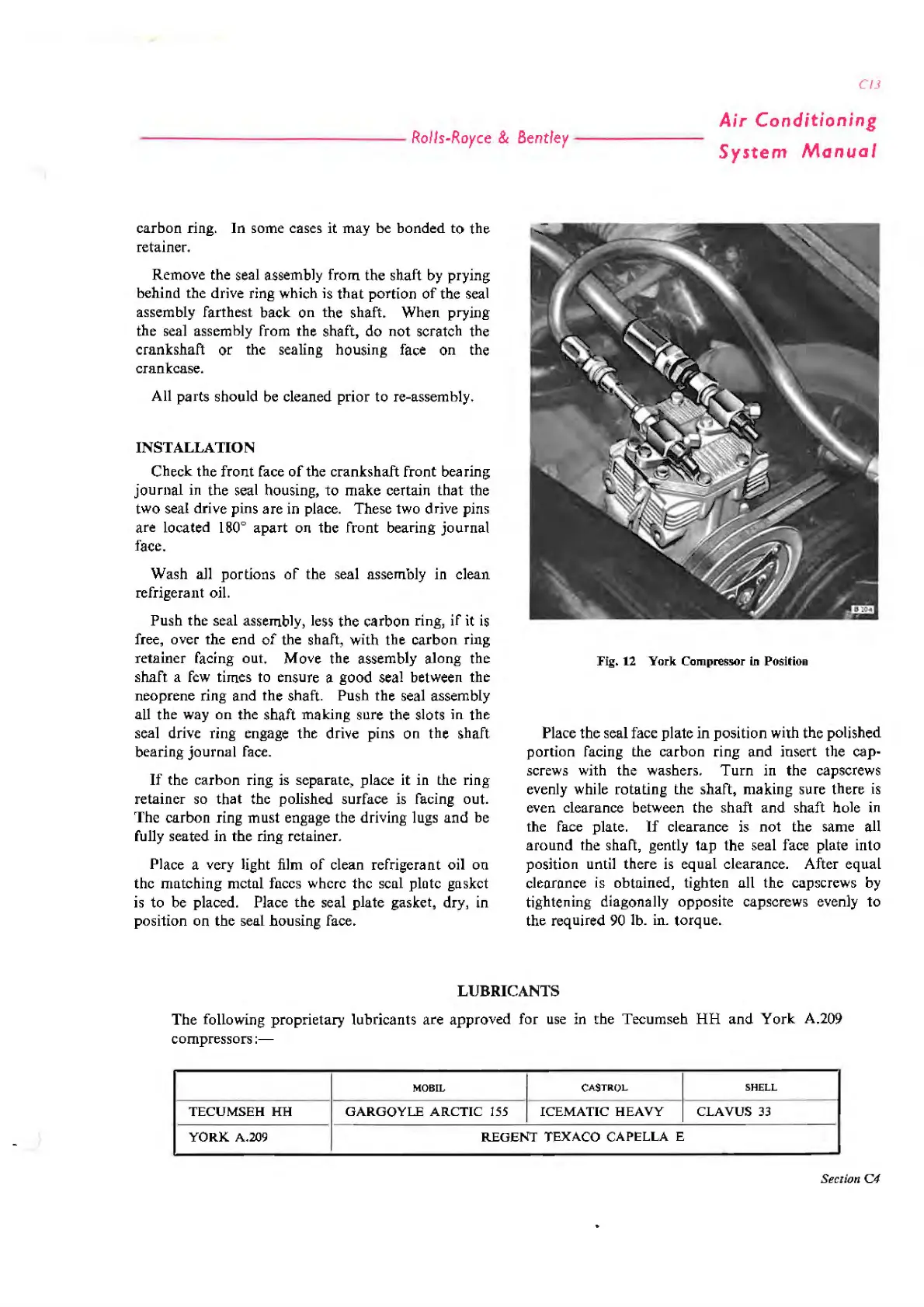

LUBRICANTS

The following proprietary lubricants are approved for

use

in the Tecumseh

HH

and

York

A.209

compressors:-

MOBIL

CASTROL SHELL

TECUMSEH

HH

GARGOYLE

ARCTIC

155

ICEMATIC

HEAVY

CLAVUS

33

YORK A.209

REGENT

TEXACO CAPELLA E

Section

C4

Loading...

Loading...