C/5

---------

----

Rolls-Royce

& Bentley

--

---

- -

Air

Conditioning

System

Manual

CONDENSER

The

condenser matrix

is

situated between the

radiator

matrix

and the

intake

grille (see Fig. 14).

Its purpose is

to

cool refrigerant gas delivered by the

compressor

and

condense

it;

the liquid refrigerant

then passes into the receiver.

The

matrix comprises two banks, each

of

sixteen

horizontal

tubes. A single inlet pipe conveys com-

pressed refrigerant

to

a 'Tee'

junction

at

the head

of

the matrix. This

junction

supplies the

two

banks

independently.

At

the

base

of

the matrix

another

junction

connects

them

to

the single outlet.

A by-pass pipe to the solenoid valve permits high

pressure

vapour

to

flow back

to

the suction side

of

the compressor when the valve

is

open.

THE RECEIVER

The

receiver

is

a steel container

of

welded con-

struction, secured by three bolts to a bracket forward

of

the frame

front

cross-member (see Fig. 15).

The

inlet pipe union is situated

at

the

top

of

the

container;

the

outlet

union

is

positioned midway

down

the

right-hand

end-face. Inside the receiver,

a

pipe

attached to the outlet union bends

downward

to

the base

of

the unit

in

order

to ensure

that

liquid

refrigerant only will pass

to

the drier.

A fusible plug, inserted

at

the base

of

the

unit,

prevents explosion in

the

event

of

fire. Under no

circumstances must

thi.<;

he replaced by a solid plug.

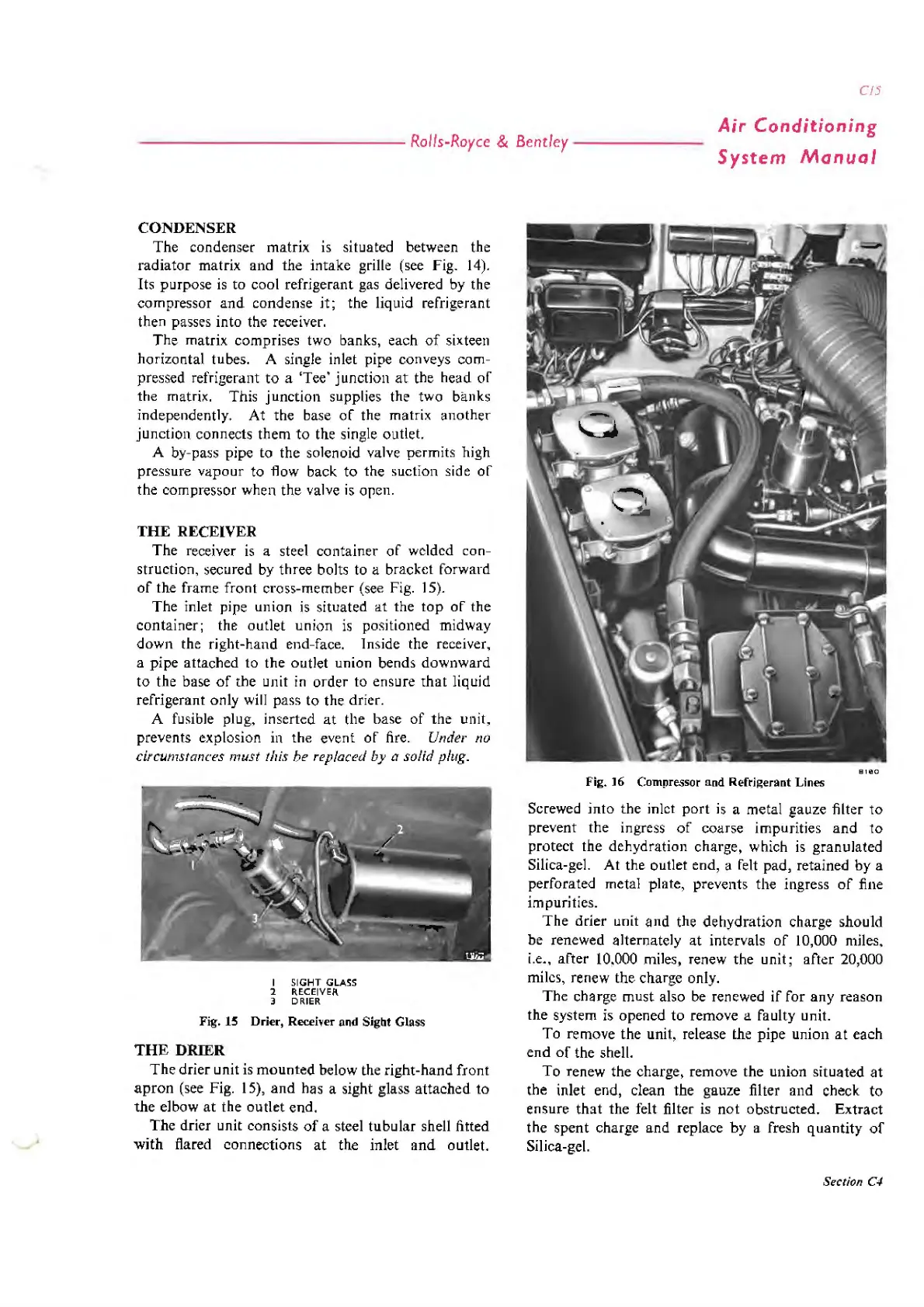

I

SIGHT

GLASS

2 RECEIVER

3

DRIER

Fig.

15

Drier, Receiver and Sight Glass

THE

DRIER

The

drier

unit is

mounted

below the right-hand

front

apron

(see Fig. 15),

and

has a sight glass

attached

to

the

elbow

at

the

outlet

end.

The

drier unit consists

of

a steel

tubular

shell fitted

with

flared connections

at

the inlet

and

outlet.

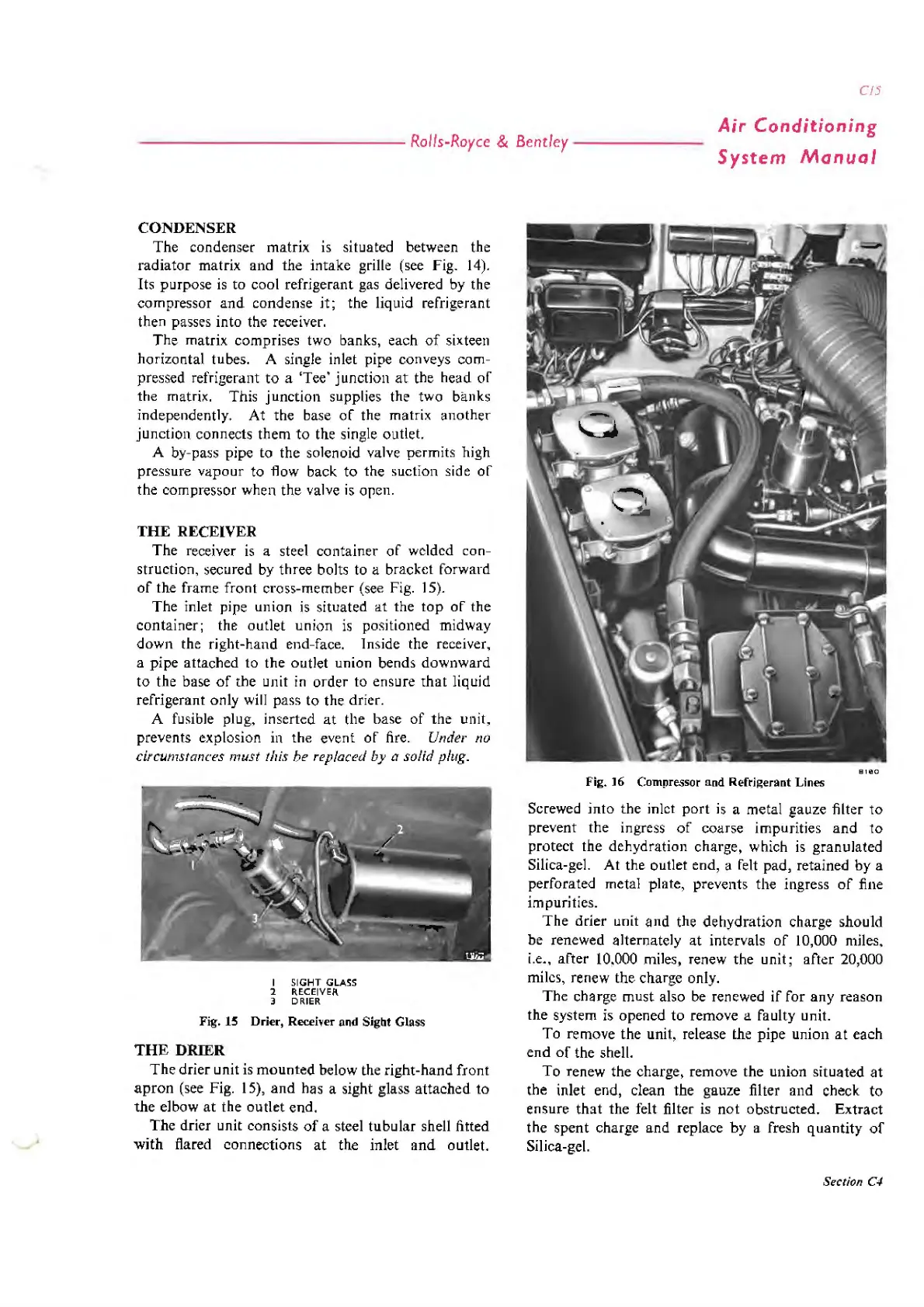

8180

Fig. 16 Compressor and Refrigerant Lines

Screwed

into

the inlet

port

is

a metal gauze filter

to

prevent the ingress

of

coarse impurities

and

to

protect the dehydration charge, which

is

granulated

Silica-gel.

At

the outlet end, a felt pad, retained

by

a

perforated metal plate, prevents the ingress

of

fine

impurities.

The

drier unit

and

the

dehydration

charge should

be

renewed alternately

at

intervals

of

10,000 miles,

i.e.,

after

10,000 miles, renew the unit;

after

20,000

miles, renew the charge only.

The

charge must also be renewed

if

for

any

reason

the system is opened

to

remove a faulty unit.

To

remove the unit, release the

pipe

union

at

each

end

of

the shell.

To

renew the charge, remove the union

situated

at

the inlet end, clean the gauze filter

and

check

to

ensure

that

the felt filter

is

not

obstructed.

Extract

the

spent

charge and replace

by

a fresh

quantity

of

Silica-gel.

Section C4

Loading...

Loading...