10

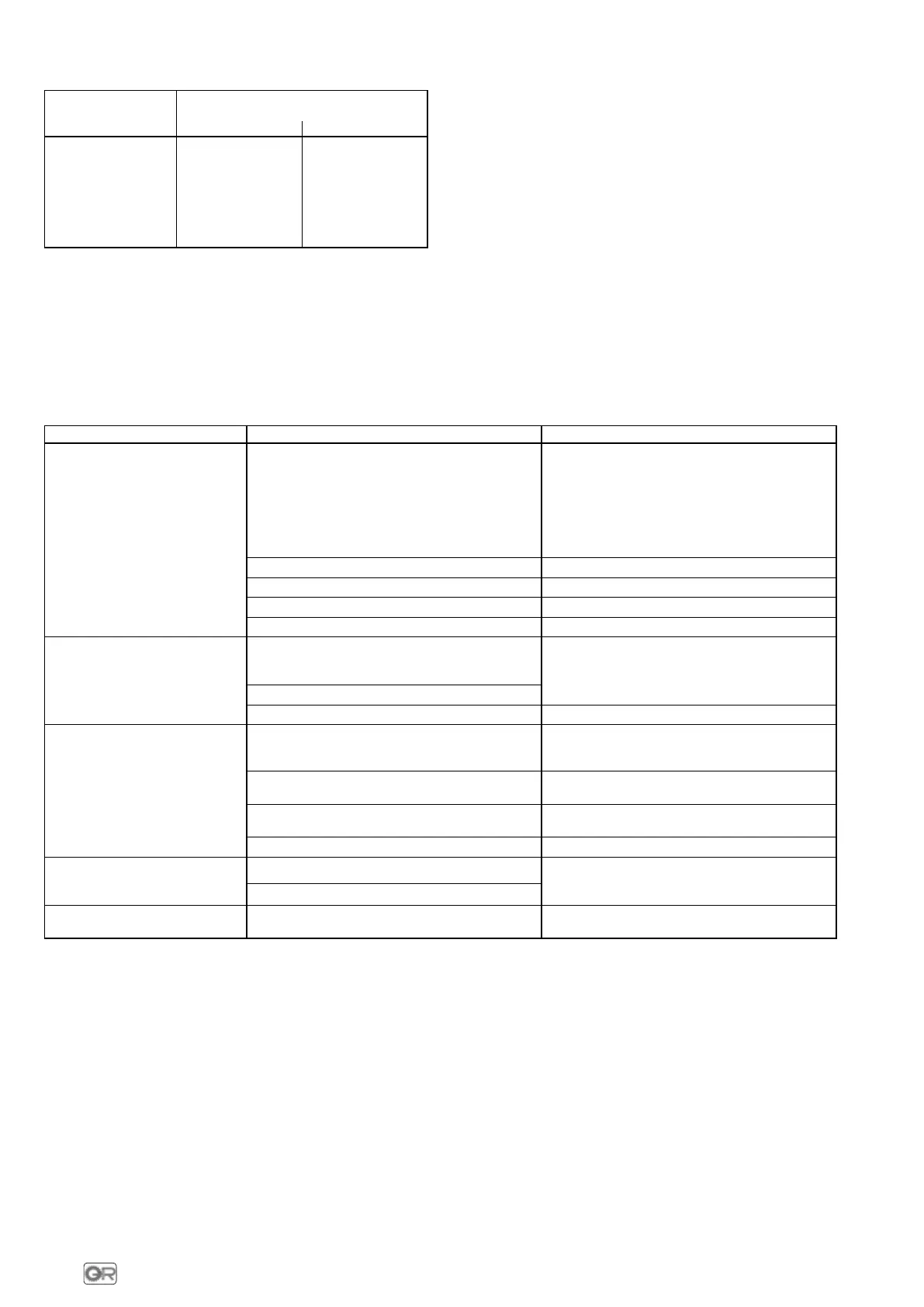

Table of tightening torques for fastening screws

bolts (foot, flange and cover lids)

Bolt

M

[N m]

UNI 5737 - 88

class 8.8 class 10.9

M 4

3 4,3

M 5

6 8,5

M 6

11 15

M 8

25 35

M10

50 71

M12

85 120

M16

205 290

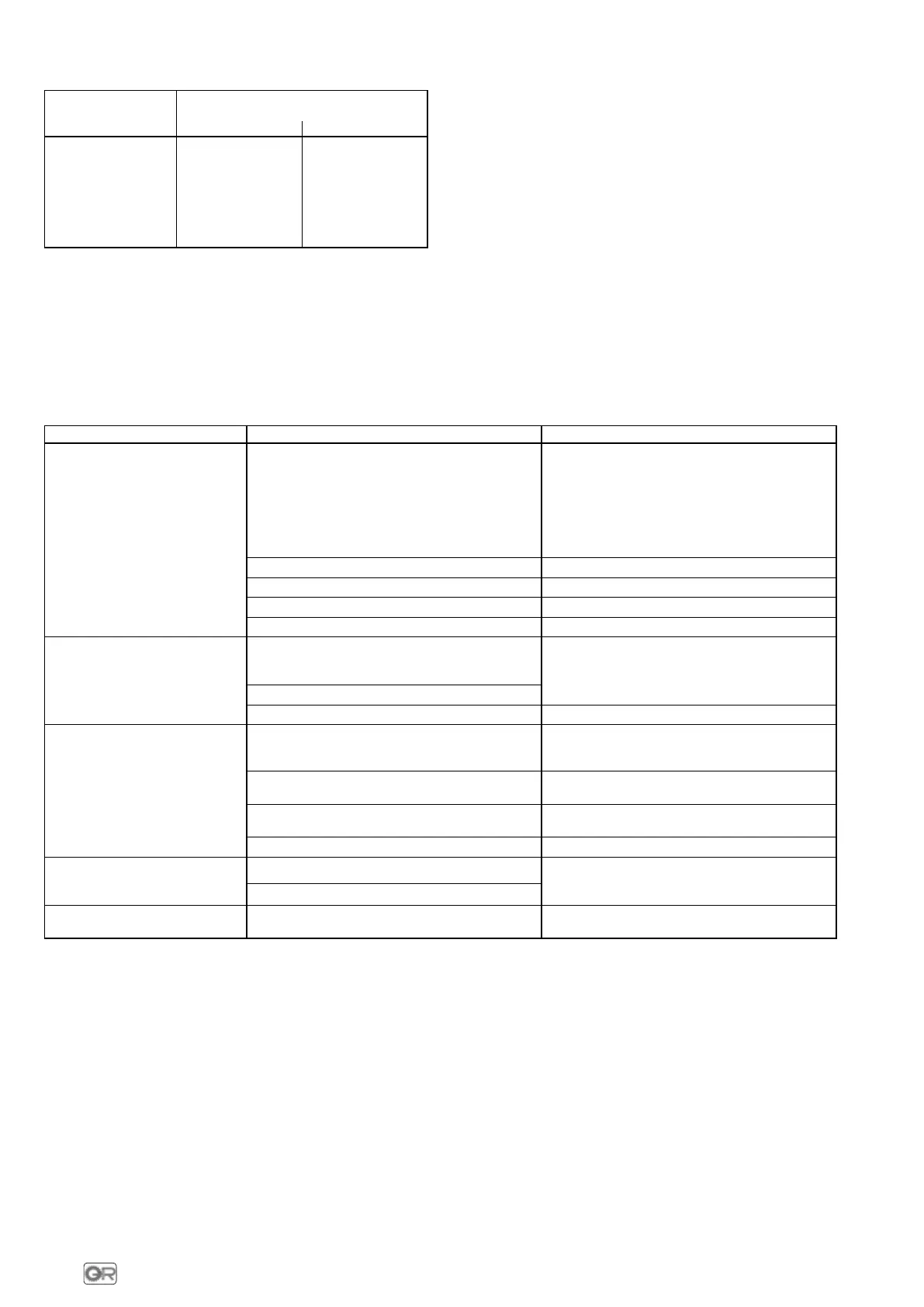

Trouble Possible causes Corrective actions

Excessive oil temperature Inadeguate lubrication:

–

excessive or insufficient oil quantity

–

unsuitable lubricant (different type, too viscous,

exhausted, ecc.)

–

Wrong mounting position

–

Excessive ambient temperature

Check:

– oil level (gear reducer at rest) or quantity

–

lubricant type and/or state; replace if necessary

– change mounting position

– increase the cooling or correct the ambient tem-

perature

Obstructed passage of air Eliminate obstructive material

Slow or missing air recycle Arrange auxiliary ventilation

Radiance Screen gear reducer and motor properly

Worn, faulty or badly lubricated bearings Consult ROSSI MOTORIDUTTORI

Anomalous noise

One or more teeth with:

–

dents or spallings

–

excessive flanks roughness

Consult ROSSI MOTORIDUTTORI

Worn, faulty or badly lubricated bearings

Vibrations Check the fastening and the bearings

Lubricant leaking from seal rings

Seal ring with worn, bakelized, damaged or false

mounted seal lip

Replace seal ring

Damaged raceway surface (scoring, rust, dent,

etc.)

Restore the raceway

Mounting position differs from the one stated on

the name plate

Position the gear reducer correctly

Too much oil Check oil quantity

Low speed shaft not rotating

even with high speed shaft/motor

running

Broken key Consult ROSSI MOTORIDUTTORI

Completely worn gear pairs

Lubricant leaking from cover lids

Defective oil seals Consult ROSSI MOTORIDUTTORI

Gear reducer troubles:causes and corrective actions

Motor: see specific instructions.

NOTE

When consulting ROSSI MOTORIDUTTORI state:

–

all data of gearmotor name plate;

–

nature and duration of failure;

–

when, under which conditions, and in which way (systematically or occasionally) the failure occured;

–

during the warranty period, in order not to loose validity, do not disassemble nor tamper the gear reducer or gearmotor without approval

by ROSSI MOTORIDUTTORI.

Notes

- Class 8.8 is usually sufficient (gearmotors are supplied with screws and bolts

class.8.8).

-

Before tightening the bolt be sure that the centering of flanges are inserted properly

- The bolts are to be diagonally tightened with the maximum tightening torque.

Loading...

Loading...