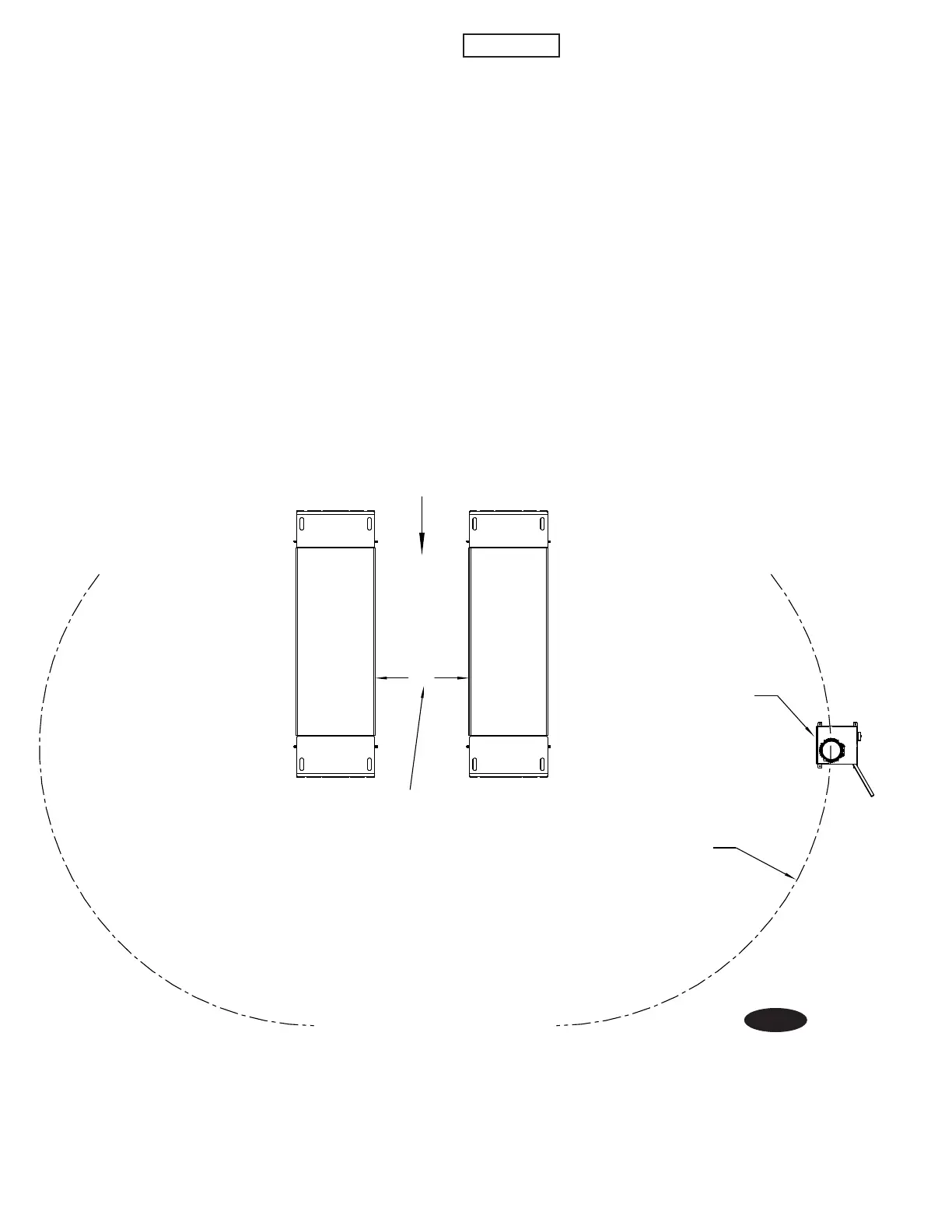

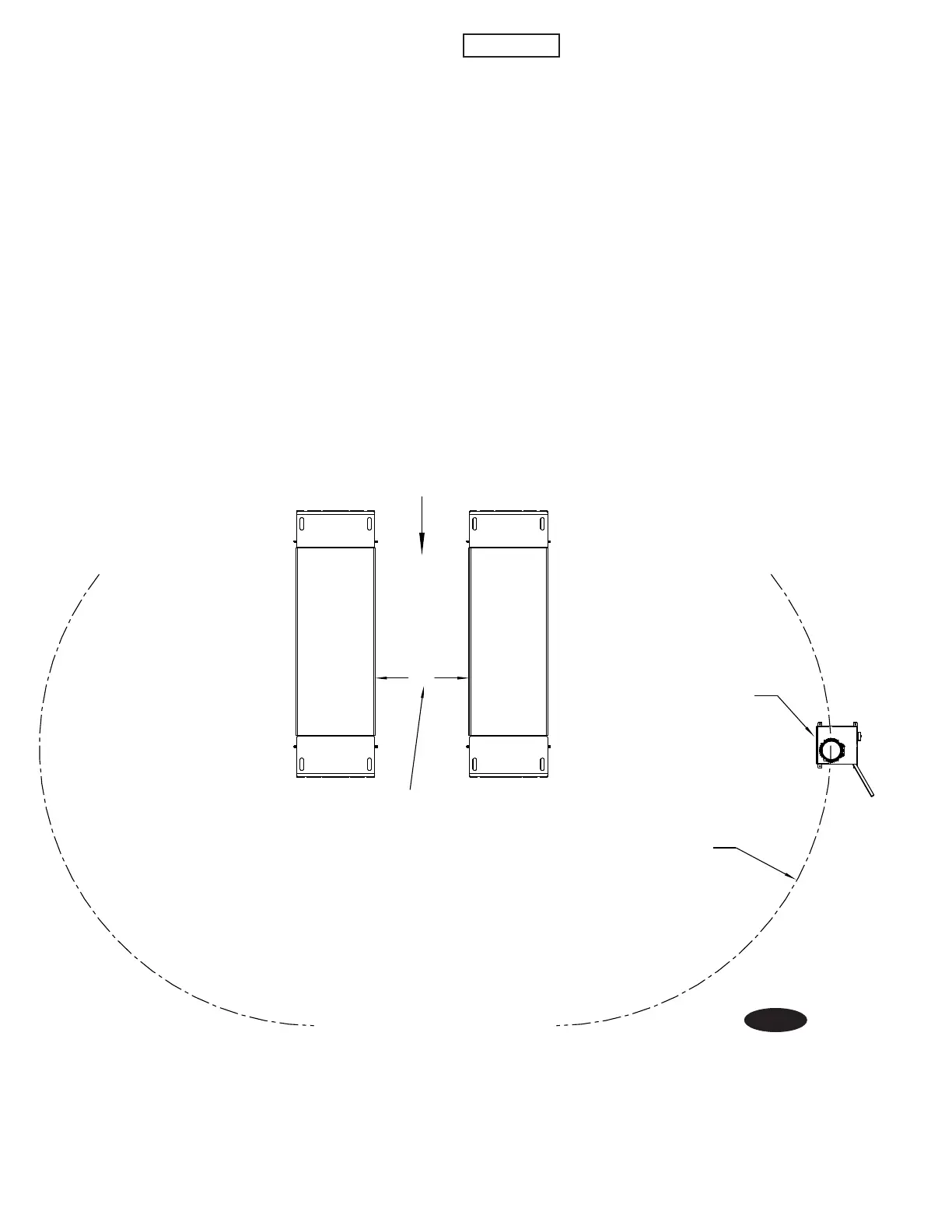

9. Platforms and Control Cabinet Detail Layout

Place platforms and control cabinet as shown in Fig. 3

for surface mount or flush mount applications.

DO NOT anchor any components at this time. The

control cabinet should be located on the opposite

end of vehicle approach, as shown in Fig. 3. Operator

should be in a position to notice any misalignment of

lifting pads or vehicle during operation. Rotary Lift

does not recommend placing the control cabinet in a

different location orientation and doing so would be

the responsibility of the installer and/or end user.

*750

CONTROL CABINET PLACEMENT

DISTANCE BETWEEN

PLATFORMS

CONTROL CABINET SHOULD BE

ORIENTED SO THAT OPERATOR

FACES LIFT WHEN OPERATING

CONTROLS

DIRECTION

OF APPROACH

CONTROL CABINET PLACEMENT ENVELOPE

MAXIMUM 5 METERS FROM EDGE OF LIFT PLATFORM,

MINIMUM 1.5 METERS FROM EDGE OF LIFT PLATFORM,

EITHER FRONT SIDE OF LIFT (HOSE SIDE)

(OPTIONS AVAILABLE FOR HOSE EXTENSIONS

AND ADDITIONAL HOSE COVERS IF EXCEED

5 METERS ENVELOPE)

*NOTE: 750mm WILL ACCOMMODATE MOST

VEHICLES. LIFT MAY BE ADJUSTED DURING

INSTALLATION BUT DISTANCE BETWEEN

PLATFORMS SHOULD NOT EXCEED 912mm.

Fig. 3

IMPORTANT

Control cabinet should always be

oriented so operator is facing the direction of the lift

when operating the lift.

If lift will be a flush mount application, the total run

length of the pipe chase from pit to bottom rear of

control cabinet should not exceed 2000mm.

10

Loading...

Loading...