52

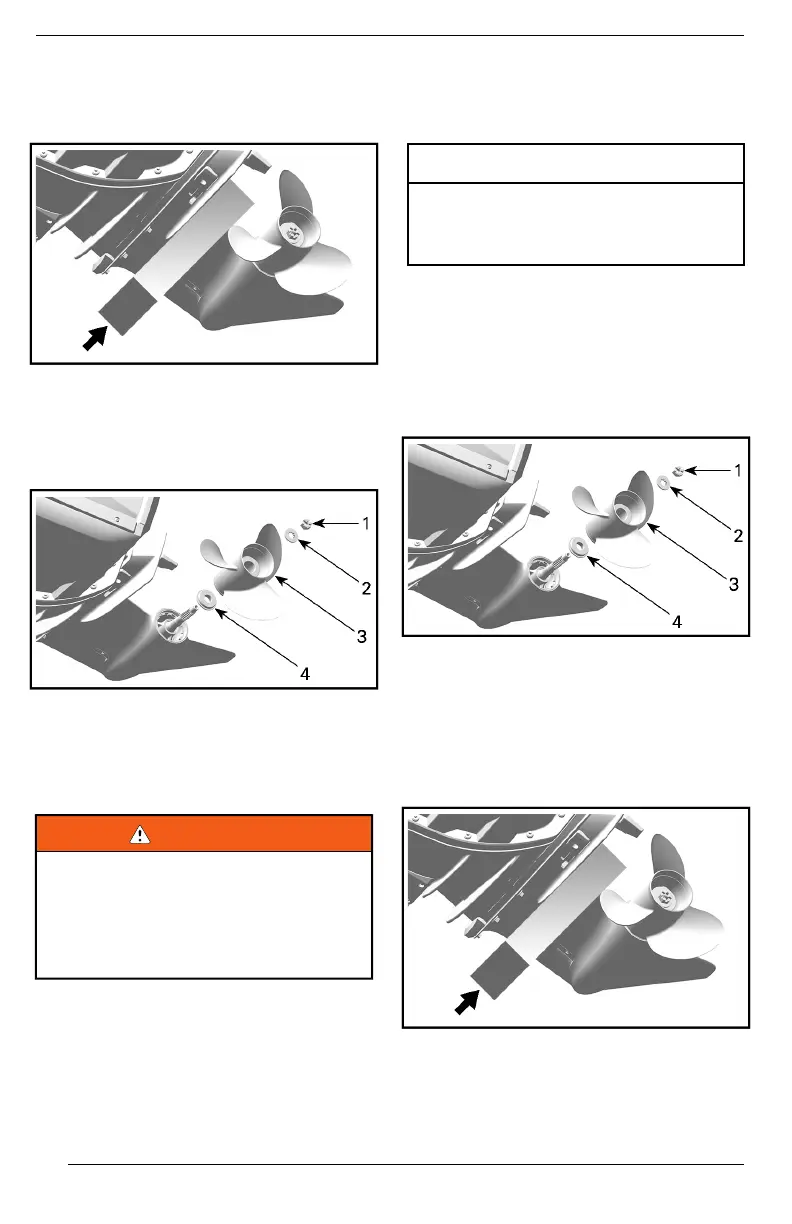

2. Wedge a block of wood between

the propeller blade and the anti--

ventilation plate.

3. Remove the slotted nut, and then

remove the block of wood.

4. Remove the spacer.

5. Remove the propeller.

6. Remove the thrust bushing.

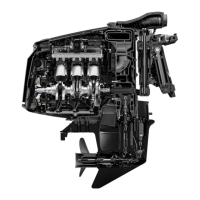

1. Slotted nut

2. Spacer

3. Propeller

4. Thrust bushing

IInnssttaalllliinngg tthhee PPrrooppeelllleerr

WWAARRNNIINNGG

WWhheenn sseerrvviicciinngg tthhee pprrooppeelllleerr,, aall--

wwaayyss sshhiifftt tthhee oouuttbbooaarrdd ttoo tthhee

NNEEUUTTRRAALL ppoossiittiioonn,, ttuurrnn tthhee kkeeyy

sswwiittcchh OOFFFF,, aanndd rreemmoovvee tthhee kkeeyy

ssoo tthhee oouuttbbooaarrdd ccaannnnoott bbee ssttaarrtteedd

aacccciiddeennttaallllyy..

IIMMPPOORRTTAANNTT:

Rotax E-TEC

out-

board engines REQUIRE propeller

hardware kit, P/N 5012290. This kit

can be ordered from an authorized

BRP dealer.

1. Apply

Triple Guard

grease to the

entire propeller shaft before instal-

ling the propeller.

RReeqquuiirreedd PPrroodduucctt

TTrriippllee GGuuaarrdd ggrreeaassee

PP//NN 550088229988

2. Install the thrust bushing so that

the taper of the bushing matches

the taper of the shaft.

3. Align the splines of the propeller

with the splines of the propeller

shaft. Push the propeller until it is

seated on the thrust bushing.

4. Install the spacer.

1. Slotted nut

2. Spacer

3. Propeller

4. Thrust bushing

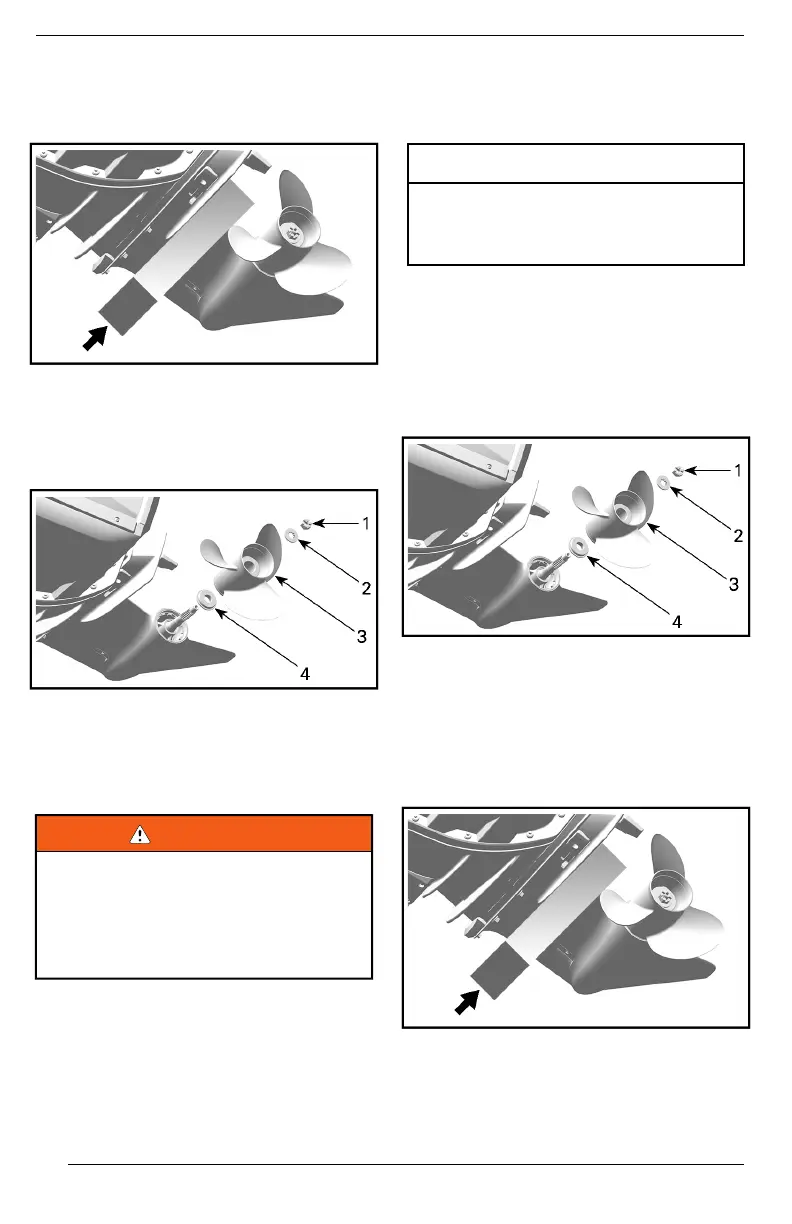

5. Wedge a block of wood between

the propeller blade and the anti--

ventilation plate.

6. Tighten the slotted nut to a torque

of 120 to 144 in·lb (13.6 to 16.3

MAINTENANCE PROCEDURES

Loading...

Loading...