2 x Operation

FA ROTEX RoCon HP - 03/2013

13

Function heating

Function heating verifies that the installation is fault-free for the

heating engineer. A pre-printed heating up report, referring to

ROTEX underfloor heating can be found at the internet portal at

http://www.rotex.de.

In this case, function heating (identical with "Heating up" in

EN 1264, section 5.2) does not constitute a heating up process

for drying and curing. Normally you need to carry out separate

heating process to cure the floor and/or perform mechanical

drying.

Heating up should be carried out no earlier than after 21 days for

cement screed, and no earlier than after 7 days for anhydrite

screed in accordance with the details provided by the manufac-

turer. The first heating up starts at a feed temperature of 25 °C,

which must be maintained for a period of 3 days. Then heating is

carried out at the maximum flow temperature set for the heating

circuit (limited to max. 55 °C) and this is then held for a further

4 days.

As a result of the insulating effect of the DUO heating pipe on

System 70, the screed function is carried out at higher tempera-

tures. On System 70, the heating up starts at a temperature of

38 °C, which is held for a period of 3 days. After that, the set

maximum heating circuit temperature (limited to 70 °C) is held for

4 days.

After the heating up process described, there is no guarantee that

the screed has achieved the moisture content required to cure

the floor.

You must determine the moisture content in the screed by

measurement before laying the floor covering.

Ready-to-apply heating

The drying out procedure for the screed cannot be predicted

exactly in advance. At higher humidity levels in the air this can

come to a complete stop under certain circumstances. The drying

out process may be accelerated by running the underfloor

heating (curing heating) or by using measures such as

mechanical drying.

Every curing heating process must be commissioned separately

by the building owner as an extra service in accordance with

VOB. For the flooring contractor to achieve fault-free installation,

the flooring must be properly cured before work is started on the

top flooring layer.

The standard functions shown in the following illustrations for

curing heating can be adjusted in order to achieve a residual

moisture level in the screed required by the curing process. The

residual moisture level in the screed must, however, always be

checked by measurement before the floorcovering is laid.

More detailed explanations and possible setting values for this function can be seen

in chapter 3.2.

2.4.7 Whisper mode

Whisper mode means that the exterior heat pump unit is

operating at reduced output. This reduces the operating noise

caused by the exterior heat pump unit.

The whisper mode is set and turned off as follows:

Ɣ Place the rotary switch in the "Configuration" position.

Î An overview is displayed.

Ɣ Select the "System Configuration" level with the rotary switch.

Î An overview is displayed.

Ɣ Select the parameter [Quiet Mode] with the rotary switch.

Ɣ Select and change the value to be changed within the

individual display using the rotary switch.

Ɣ Confirm the changes with a brief push of the rotary switch.

Î Change has been accepted. Jump back to previous dis-

play.

More detailed explanations and possible setting values for this function can be seen

in chapter

3.2.

Procedure in accordance with EN 1264 part 4:

The heating circuits must be checked for leaks by a

water pressure test once the anhydrite and cement

screeds are completed. The absence of leaks must be

ensured immediately before and during screed laying.

The level of the test pressure is at least 1.3 times the

maximum permissible operating pressure.

If there is a danger of freezing up, you must take suita-

ble measures, e.g. the use of antifreeze or temperature

control in the building. If antifreeze is no longer required

for intended use of the installation, you must remove

the antifreeze by draining it out and flushing the instal-

lation with at least 3 changes of water.

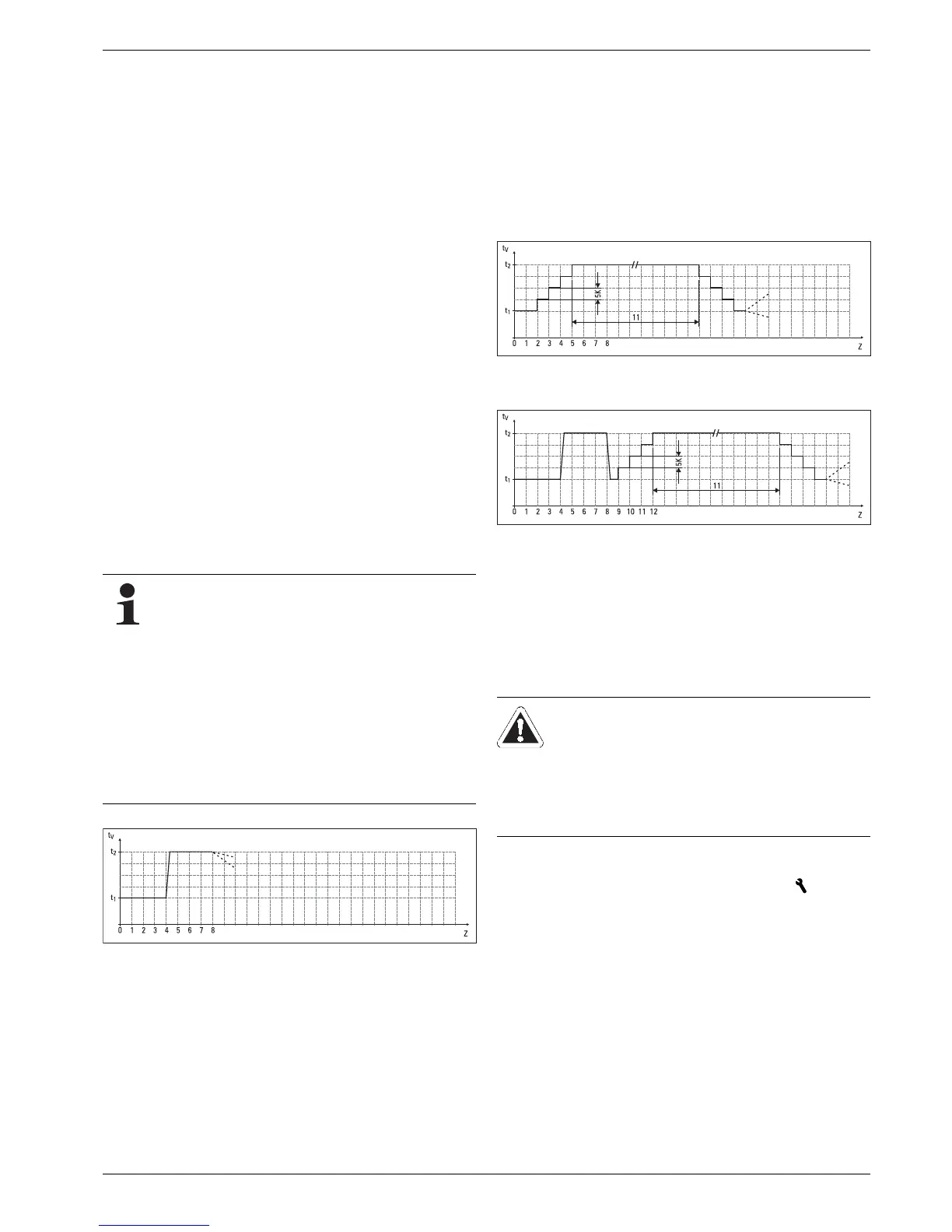

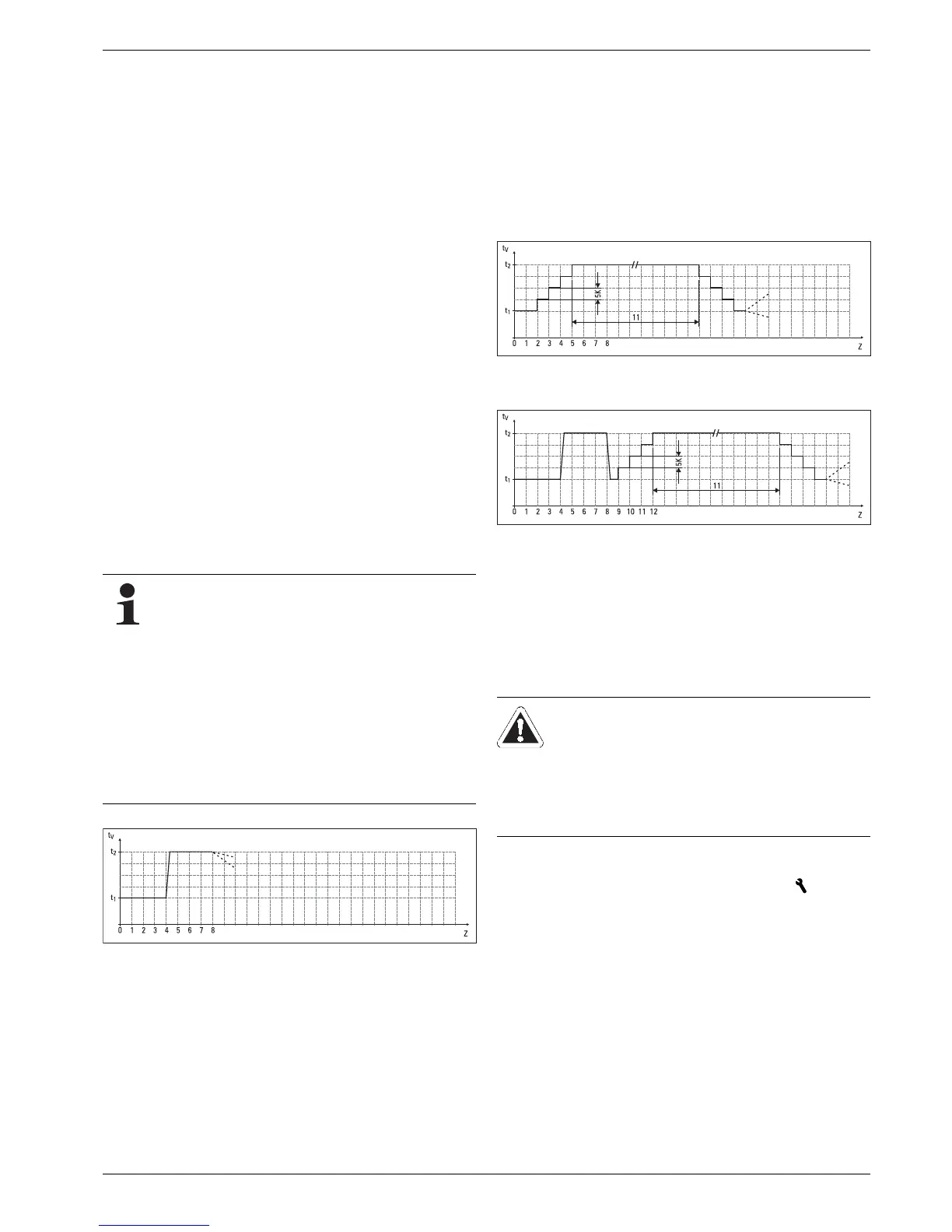

t

1

Starting temperature 25°C (38°C on System 70)

t

2

Maximum heating circuit temperature

T

V

Flow temperature

Z Duration of screed function, in days, after function start

Fig. 2-10 Time sequence of screed function in function heating

Fig. 2-11 Time sequence of screed function in curing heating (for legend

see

fig. 2-10)

Fig. 2-12 Time sequence of screed function in combined function and

curing heating (for legend see fig. 2-10)

CAUTION!

The operating mode "Whisper mode" reduces the

performance in room heating and room cooling

operation with the result that it may no longer be

possible to reach the preset target temperatures.

Ɣ With outside temperatures below freezing, there is

a risk of material damage caused by frost.

Loading...

Loading...