6 Preparation

Installer reference guide

26

RRLQ004~008CA + RHBH/X04+08CB

ROTEX HPSU low temperature Bi‑bloc

4P384979-1C – 2017.04

▪ You might need to adjust the pre-pressure of the expansion

vessel.

Minimum water volume

Check that the total water volume in the installation is minimum

10litre, the internal water volume of the indoor unit NOT included.

INFORMATION

In critical processes, or in rooms with a high heat load,

extra water might be required.

NOTICE

When circulation in each space heating/cooling loop is

controlled by remotely controlled valves, it is important that

the minimum water volume is guaranteed, even if all of the

valves are closed.

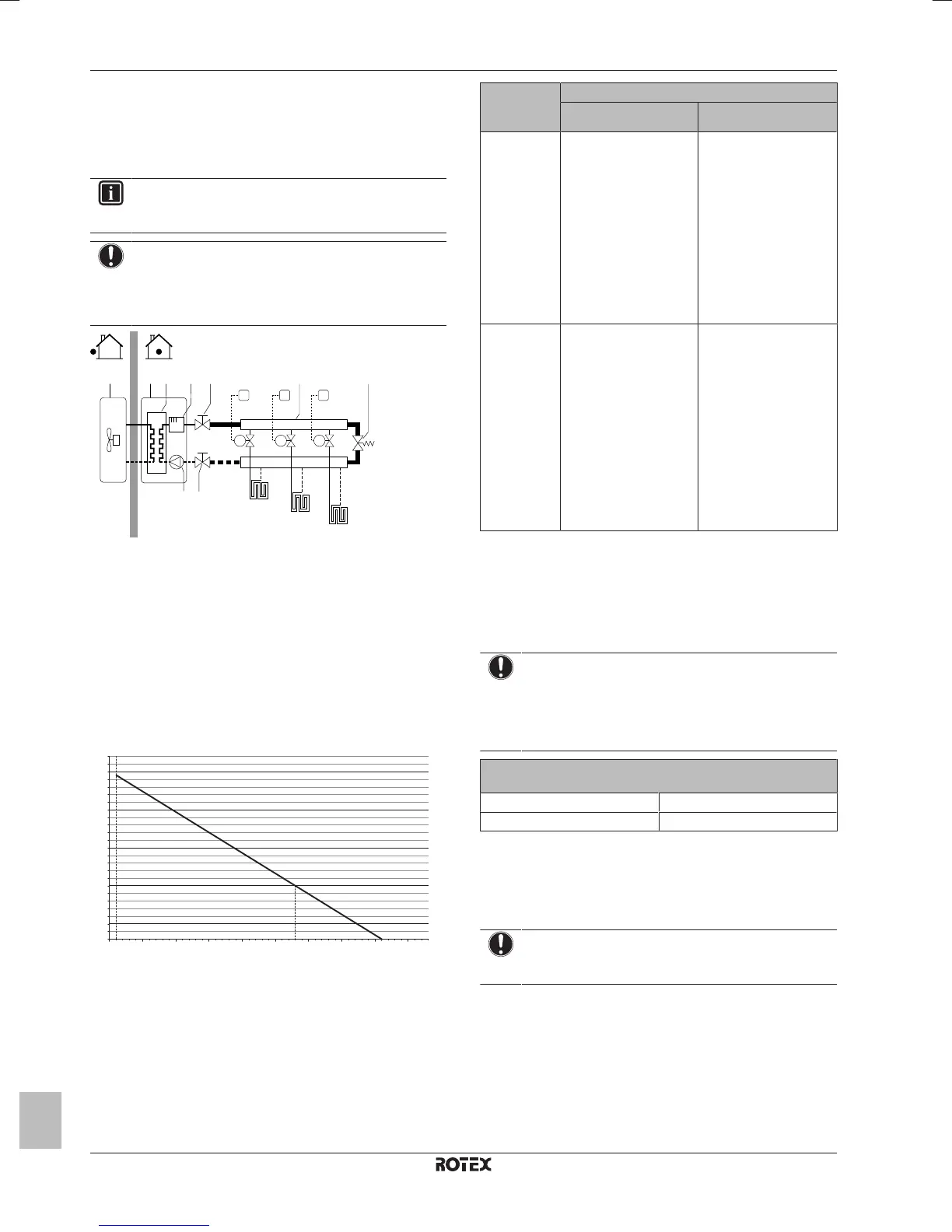

FHL1

FHL2

FHL3

M1

T1

M2

T2

M3

T3

fdcba

f

g h

e

a Outdoor unit

b Indoor unit

c Heat exchanger

d Backup heater

e Pump

f Shut-off valve

g Collector (field supply)

h By-pass valve (field supply)

FHL1...3 Floor heating loop (field supply)

T1...3 Individual room thermostat (optional)

M1...3 Individual motorised valve to control loop FHL1...3 (field

supply)

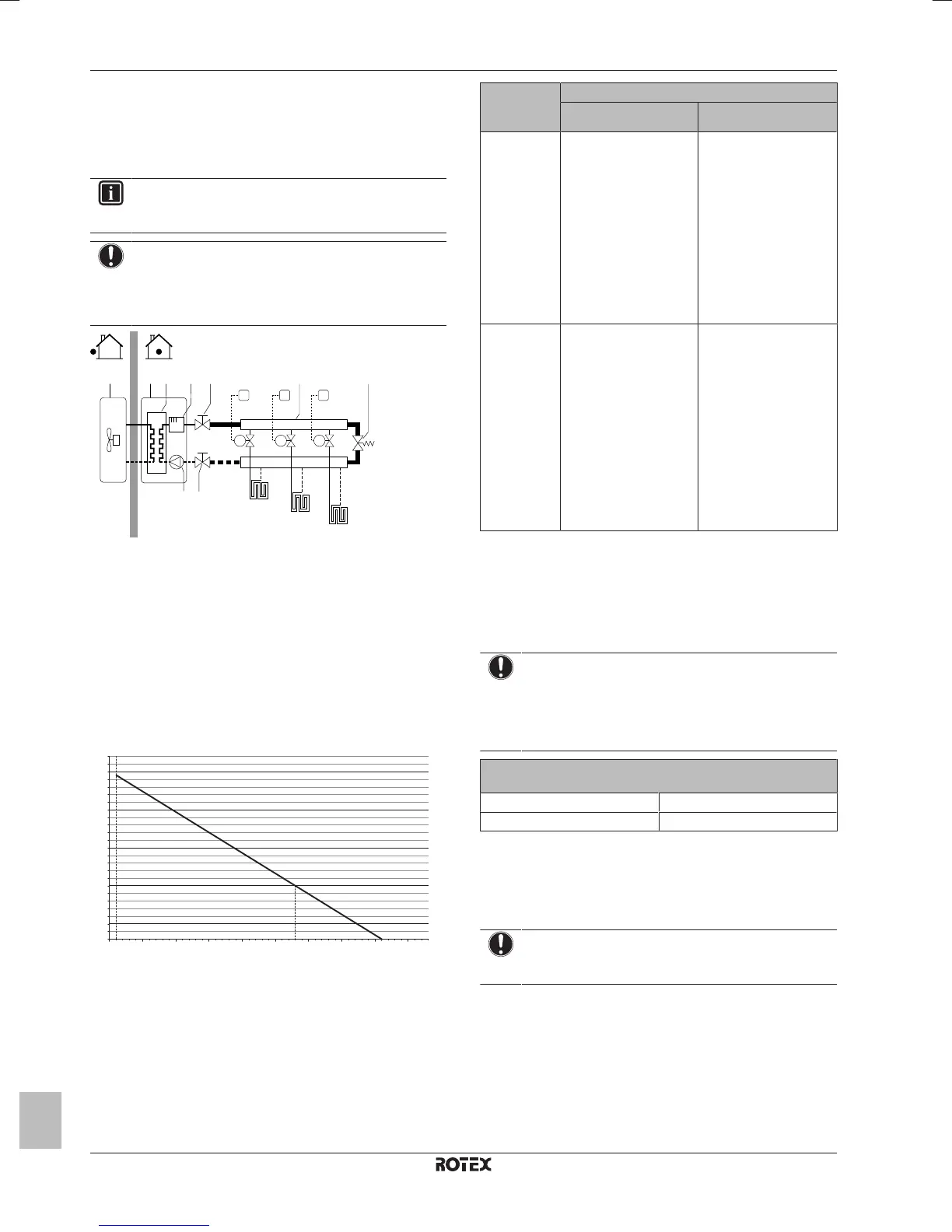

Maximum water volume

Use the following graph to determine the maximum water volume for

the calculated pre-pressure.

0.3

0.5

1

1.5

2

2.5

100500

10

150 200 250 300 350 400 450

a

b

a Pre-pressure (bar)

b Maximum water volume (l)

Example: Maximum water volume and expansion vessel pre-

pressure

Installation

height

difference

(a)

Water volume

≤280l >280l

≤7m No pre-pressure

adjustment is required.

Do the following:

▪ Decrease the pre-

pressure according to

the required installation

height difference. The

pre-pressure should

decrease by 0.1 bar for

each metre below 7 m.

▪ Check if the water

volume does NOT

exceed the maximum

allowed water volume.

>7m Do the following:

▪ Increase the pre-

pressure according to

the required

installation height

difference. The pre-

pressure should

increase by 0.1 bar for

each metre above 7 m.

▪ Check if the water

volume does NOT

exceed the maximum

allowed water volume.

The expansion vessel of

the indoor unit is too

small for the installation.

In this case, it is

recommended to install

an extra vessel outside

the unit.

(a) This is the height difference (m) between the highest point

of the water circuit and the indoor unit. If the indoor unit is

at the highest point of the installation, the installation height

is 0m.

Minimum flow rate

Check that the minimum flow rate (required during defrost/backup

heater operation) in the installation is guaranteed in all conditions.

NOTICE

When circulation in each or certain space heating loops is

controlled by remotely controlled valves, it is important that

the minimum flow rate is guaranteed, even if all valves are

closed. In case the minimum flow rate cannot be reached,

a flow error 7H will be generated (no heating/operation).

Minimum required flow rate during defrost/backup heater

operation

04+08 models 12l/min

11+16 models 15l/min

See the recommended procedure as described in "9.4 Checklist

during commissioning"on page73.

6.4.4 Changing the pre-pressure of the

expansion vessel

NOTICE

Only a licensed installer may adjust the pre-pressure of the

expansion vessel.

When changing the default pre-pressure of the expansion vessel

(1bar) is required, take following guidelines into account:

▪ Only use dry nitrogen to set the expansion vessel pre-pressure.

▪ Inappropriate setting of the expansion vessel pre-pressure will

lead to malfunction of the system.

Changing the pre-pressure of the expansion vessel should be done

by releasing or increasing nitrogen pressure through the Schrader

valve of the expansion vessel.

Loading...

Loading...